Electret microphone

An electret microphone and back electrode technology, applied in the field of microphones, can solve the problems of low surface flatness, low product qualification rate, poor performance, etc., and achieve the effects of simple production process adjustment, improved production qualification rate, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

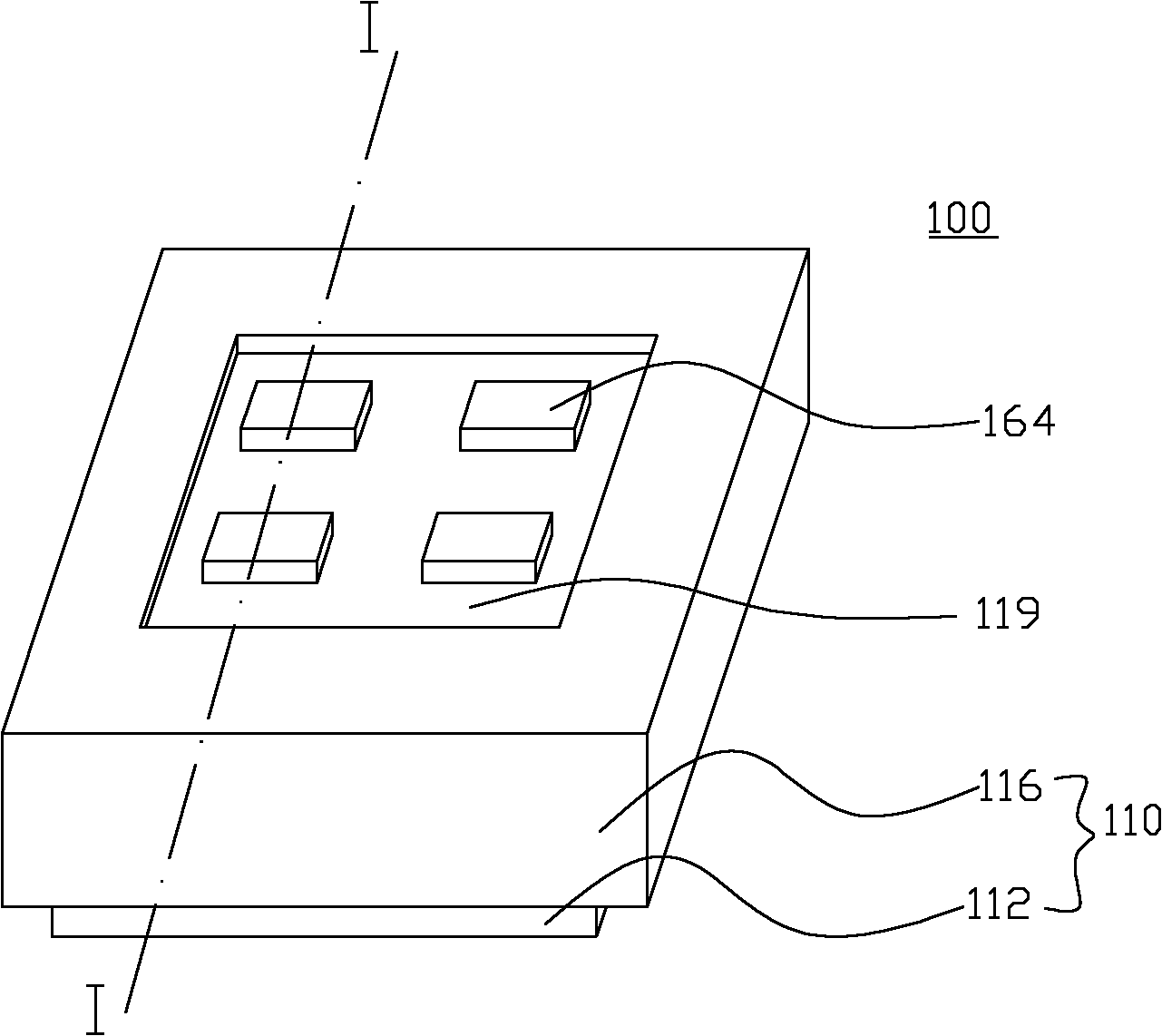

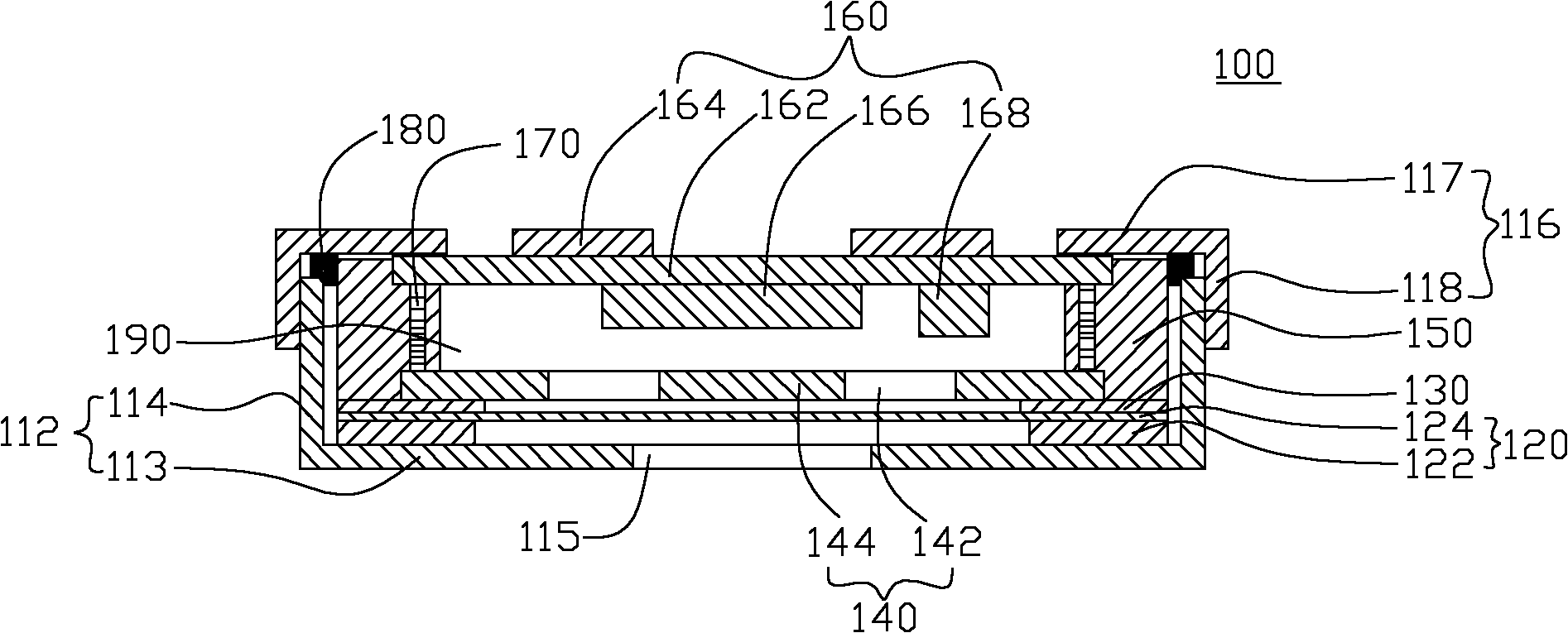

[0023] Such as figure 1 with figure 2 As shown, the electret microphone 100 of this embodiment includes a casing 110 and a diaphragm assembly 120, an insulating gasket 130, a back electrode assembly 140, an insulating cavity 150, a circuit board assembly 160, and a conductive member arranged in sequence in the casing 110. 170 and seal 180. The back electrode assembly 140 is electrically connected to the circuit board assembly 160 through the conductive member 170 .

[0024] The housing 110 includes a bottom case 112 and a top case 116 . The top shell 116 is socketed with the bottom shell 112 to form a cavity for accommodating the diaphragm assembly 120, the insulating gasket 130, the back electrode assembly 140, the insulating cavity 150 and the circuit board assembly 160, wherein the circuit board assembly 160 is disposed adjacent to the top case 116 . The top 117 of the top case 116 , that is, the surface parallel to the diaphragm assembly 120 is a planar structure.

...

Embodiment 2

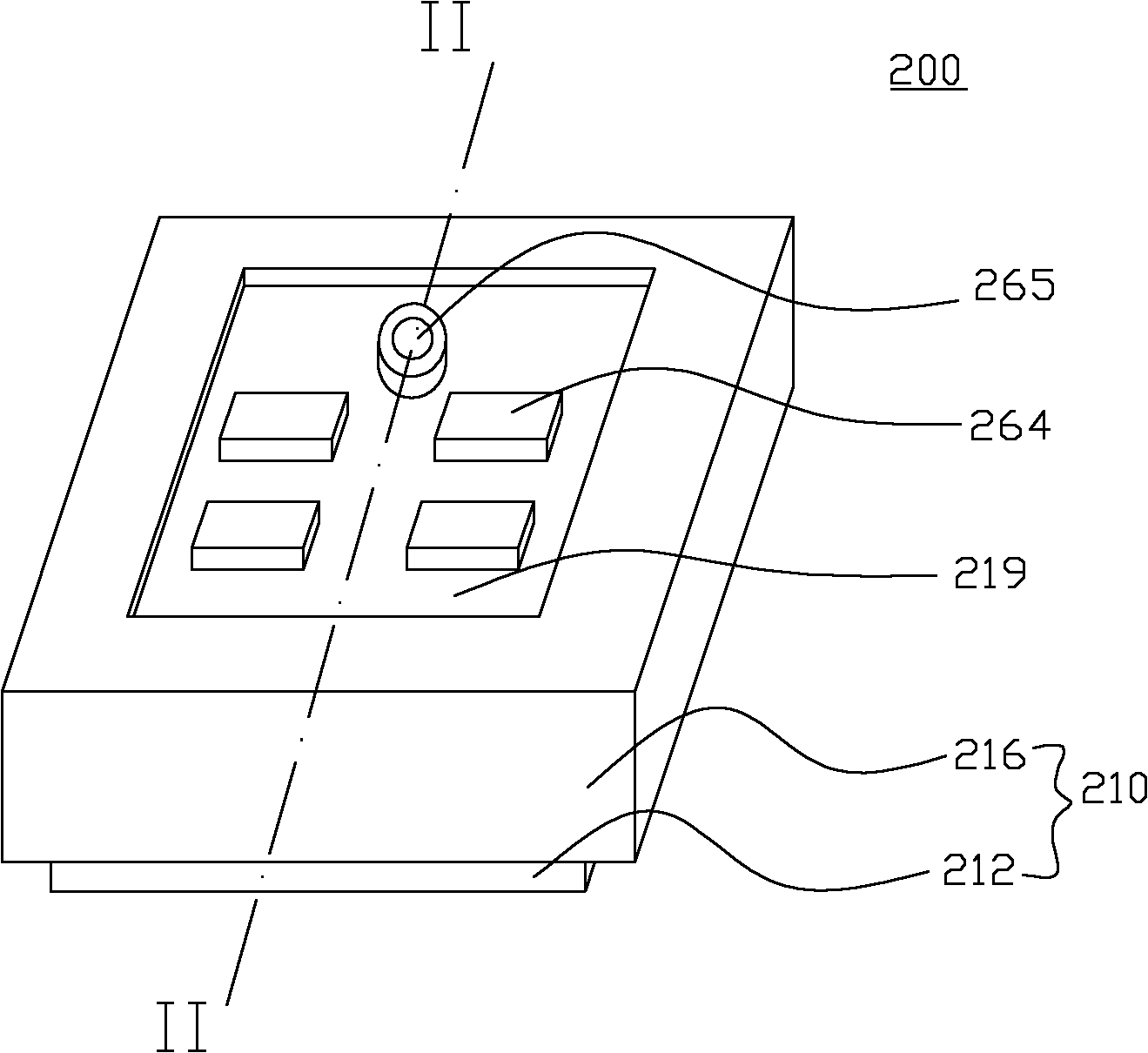

[0037] Such as image 3 with Figure 4 As shown, the electret microphone 200 of this embodiment includes a casing 210 and a diaphragm assembly 220, an insulating gasket 230, a back electrode assembly 240, an insulating cavity 250, a circuit board assembly 260, and a conductive member arranged in sequence in the casing 210. 270 and seal 280. The back electrode assembly 240 is electrically connected to the circuit board assembly 260 through the conductive member 270 .

[0038]The shell 210 is similar in structure to the first embodiment, including a bottom shell 212 and a top shell 216 . Wherein, the bottom case 212 includes a square bottom 213 and a bottom case extension 214 extending vertically along the edge of the bottom 213 . The top case 216 includes a square top 217 and a top case extension 218 extending vertically along an edge of the top 217 . The top 217 of the top case 216 , that is, the surface parallel to the diaphragm assembly 220 is a planar structure. The to...

Embodiment 3

[0044] like Figure 5 As shown, the electret microphone 300 of this embodiment includes a casing 310 and a diaphragm assembly 320, an insulating gasket 330, a back electrode assembly 340, an insulating cavity 350, a circuit board assembly 360, and a conductive member arranged in sequence in the casing 310. 370 and seal 380. The back electrode assembly 340 is electrically connected to the circuit board assembly 360 through the conductive member 370 .

[0045] The shell 310 is similar in structure to the first embodiment, including a bottom shell 312 and a top shell 316 . Wherein, the bottom case 312 includes a square bottom 313 and a bottom case extension 314 extending vertically along the edge of the bottom 313 . The top case 316 includes a square top 317 and a top case extension 318 extending vertically along an edge of the top 317 . The top 317 of the top case 316 , that is, the surface parallel to the diaphragm assembly 320 is a planar structure. An opening 319 is defin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com