Epoxy resin composition

A technology of epoxy resin and epoxy compound, which is applied in the direction of epoxy resin adhesive, modified epoxy resin adhesive, non-polymer organic compound adhesive, etc. In order to solve problems such as poor ejection performance, low initial viscosity and good ejection performance can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

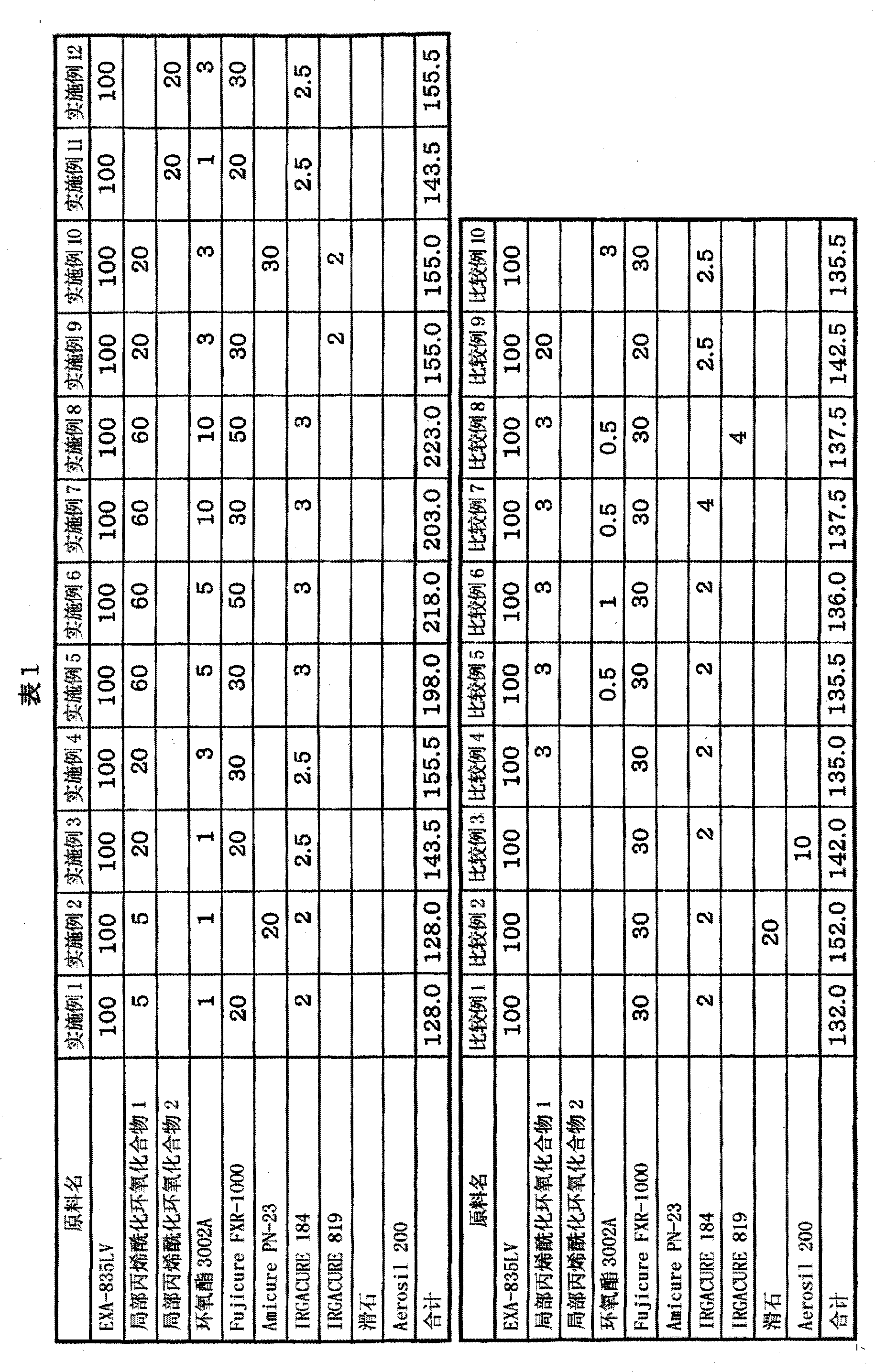

[0048] In order to prepare the epoxy resin composition, the following components were prepared.

[0049] (A) Component Epoxy compound

[0050] Liquid epoxy resin mixture of bisphenol A type and bisphenol F type: "Epiclon EXA-835LV (manufactured by Dainippon Ink Chemical Industry Co., Ltd.)"

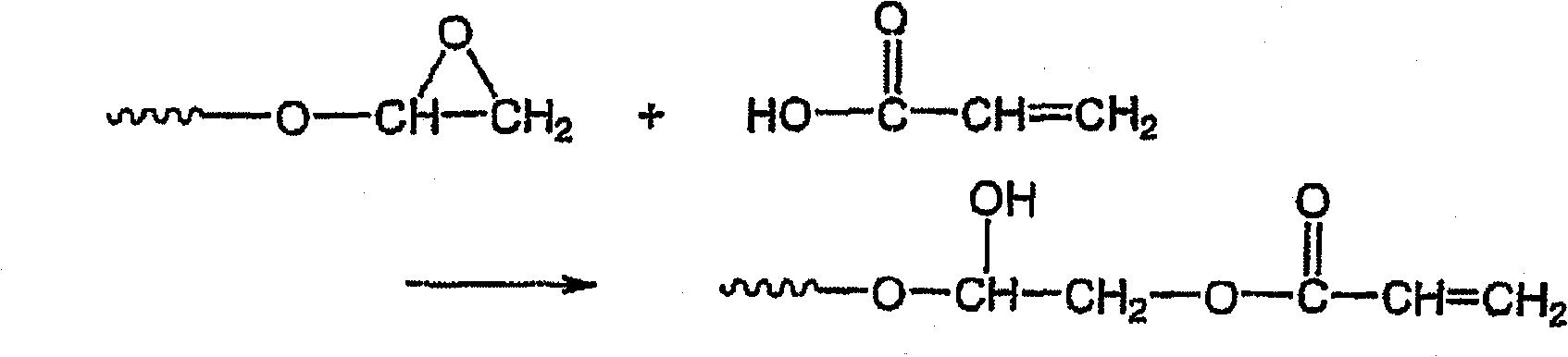

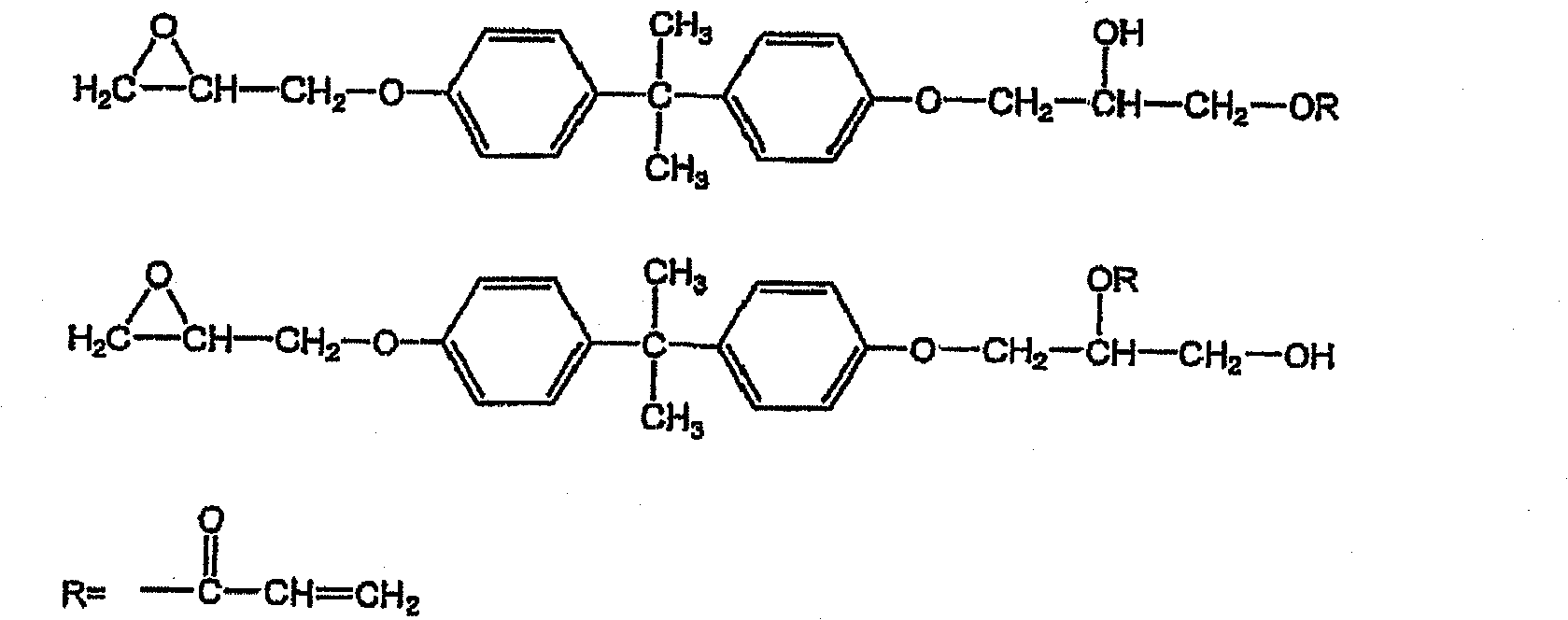

[0051] (B) Component Partially acrylated epoxy compound

[0052] ● Partially Acrylated Epoxy Compound 1

[0053] ● Partially acrylated epoxy compound 2

[0054] (C) Component (meth)acryloyl compound

[0055] Epoxy-modified acrylic compound: "Epoxy Ester 3002A (manufactured by Kyoeisha Chemical Co., Ltd.)"

[0056] (D) Component Amine curing agent

[0057] Epoxy addition curing agent: "Fujicure FXR-1000 (manufactured by Fuji Chemical Industry Co., Ltd.)"

[0058] Epoxy addition curing agent: "Amicure PN-23 (manufactured by Ajinomoto Fine Techno Co., Ltd.)"

[0059] (E) Component Photoinitiator

[0060] 1-Hydroxy-cyclohexyl-phenyl ketone "IRGACURE 184 (manufactured by Ciba Specialty...

Embodiment 1

[0111] In Examples 1 to 12, the viscosities were 10 to 51 Pa·s, and the TI values were very low, and the ejection properties were good. In addition, fluidity during heating was not observed, indicating that the discharge shape was maintained. On the other hand, in Comparative Examples 2 and 3, although thixotropy was imparted by the addition of the filler, the resin composition spread when heated, so it was not suitable for micro-amount coating. In addition, according to the comparison between Examples 1-12 and Comparative Examples 1-8, it is necessary to add both (B) component and (C) component, and for the addition amount, (B) component needs to be added at least 5 mass parts, (C) Components need to be added at least 1 part by mass. As for the amount of outgassing which is important for the HDD adhesive, it can be seen from Comparative Examples 7 and 8 that when the component (E) is added in excess, the total amount of outgassing tends to increase. In addition, when Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com