Drive control method for glow plugs

A technology of glow plug and electronic control unit, which is applied in engine control, combustion method, electrical control, etc., can solve the problems of shortening the life of ceramic glow plug, deterioration of ceramic heater, deterioration of exhaust gas characteristics, etc., to suppress harmful components, The effect of avoiding cracks and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

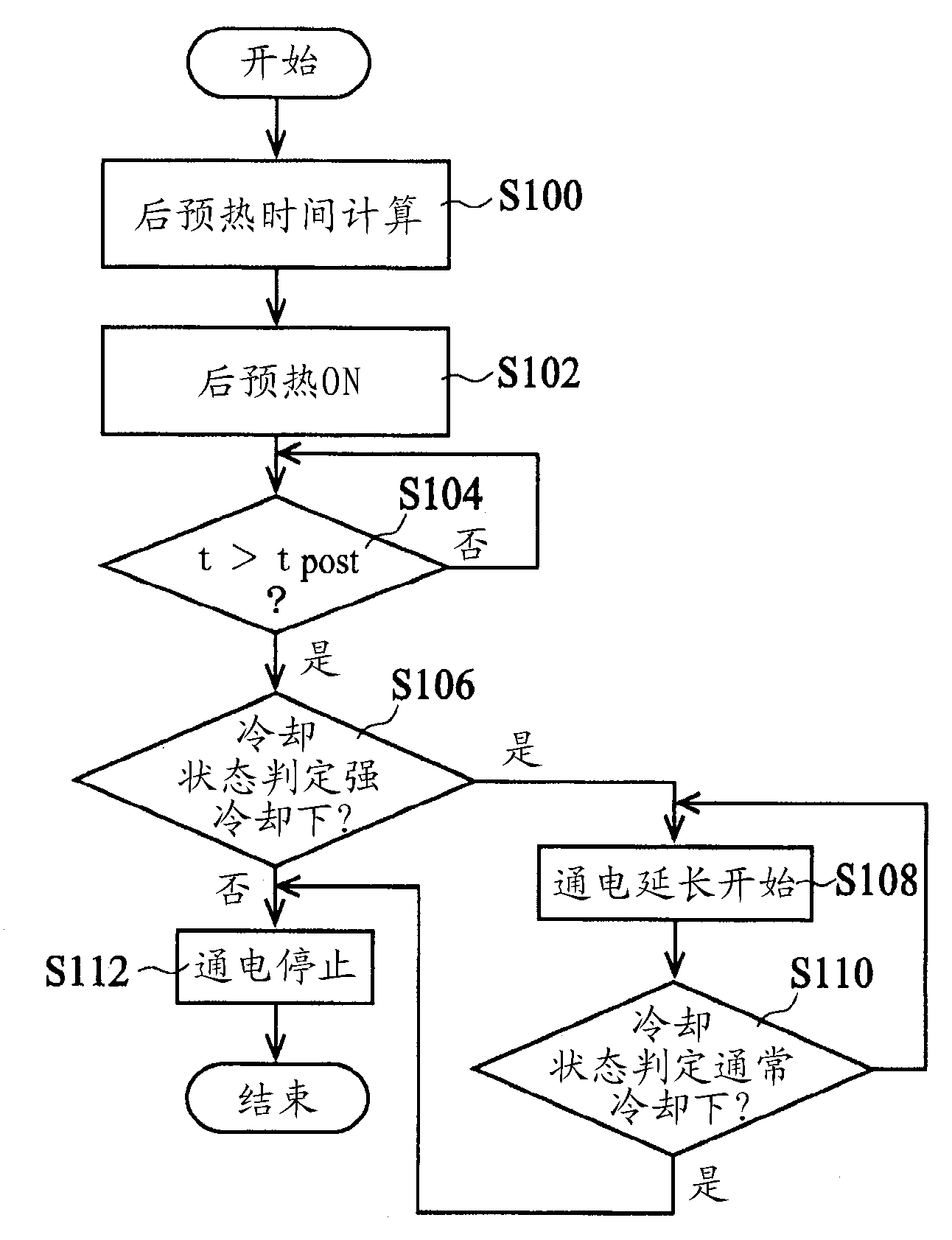

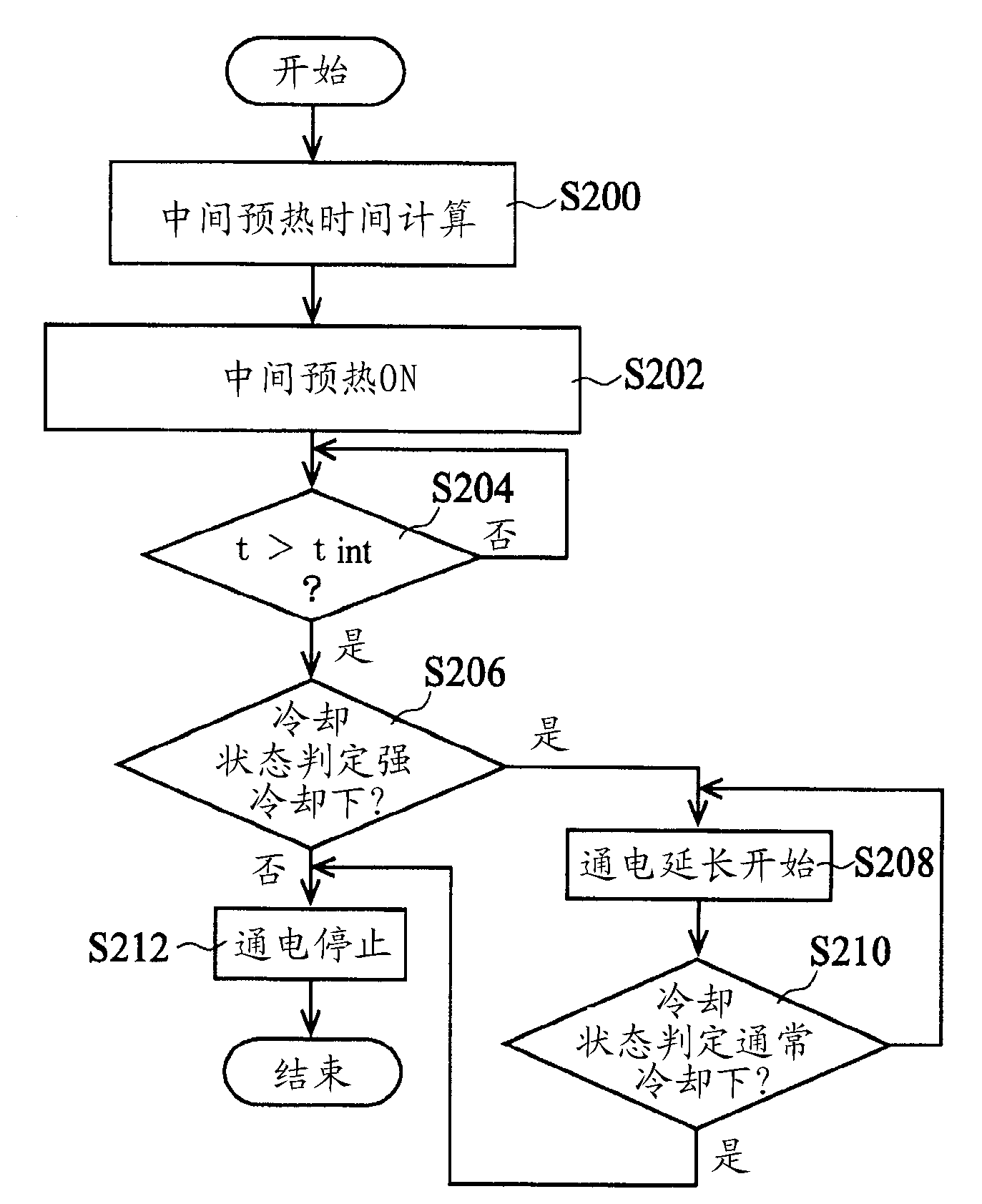

[0027] Below, refer to Figure 1 to Figure 5 Embodiments of the present invention will be described.

[0028] In addition, members, arrangements, and the like described below do not limit the present invention, and various changes can be made within the scope of the gist of the present invention.

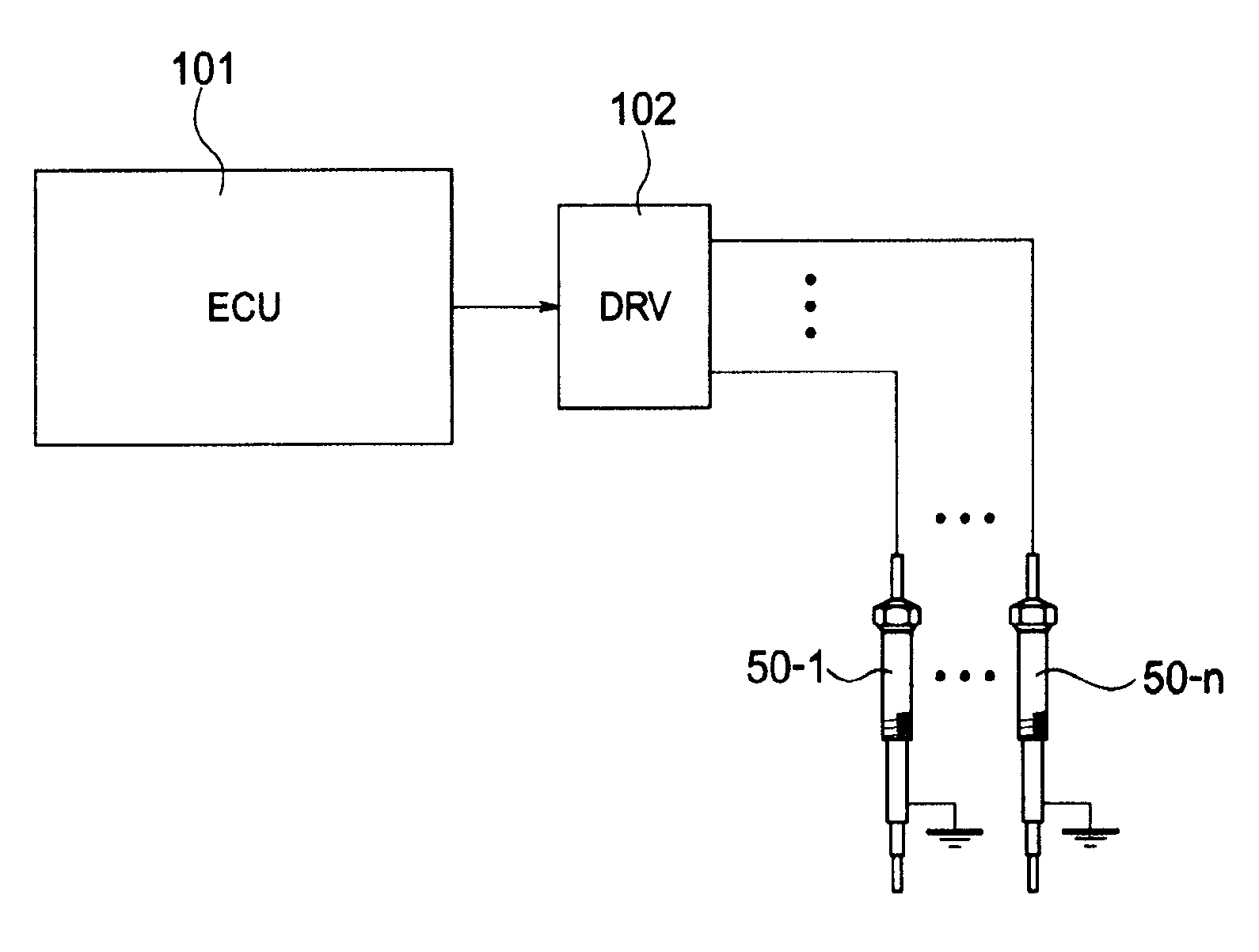

[0029] First, refer to figure 1 A configuration example of a glow plug drive control device to which the glow plug drive control method in the embodiment of the present invention is applied will be described.

[0030] The glow plug driving device in the embodiment of the present invention is roughly divided into electronic control units ( figure 1 denoted as "ECU") 101, and energized circuit ( figure 1 Denoted as "DRV") 102 and constituted.

[0031] The electronic control unit 101 is centered on, for example, a microcomputer (not shown) having a well-known and well-known configuration, has memory elements (not shown) such as RAM and ROM, and has a circuit for transmitting signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com