Forming method for resistance-change non-volatile memory element, and resistance-change non-volatile memory device

A non-volatile storage and resistance-variable technology, applied in electrical components, information storage, static memory, etc., can solve the problems of increased manufacturing deviation factors, improve data reliability, high-speed readout and improve, reduce The effect of the likelihood that misreadings will occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0127] The variable resistance nonvolatile memory device in the first embodiment of the present invention is a 1T1R nonvolatile memory device in which a variable resistance element and a MOS transistor are connected in series, and is used to provide a variable resistance element capable of controlling The high resistance level molding method and the most suitable high resistance pulse voltage application to the variable resistance element, so the high resistance state and the low resistance state have a wide operating window.

[0128] [Basic data of the present invention 1 Characteristics of variable resistance films with fixed resistance elements connected in series]

[0129] As preparation for the description, basic data related to the variable resistance element used in the variable resistance nonvolatile memory device of the present invention will be described.

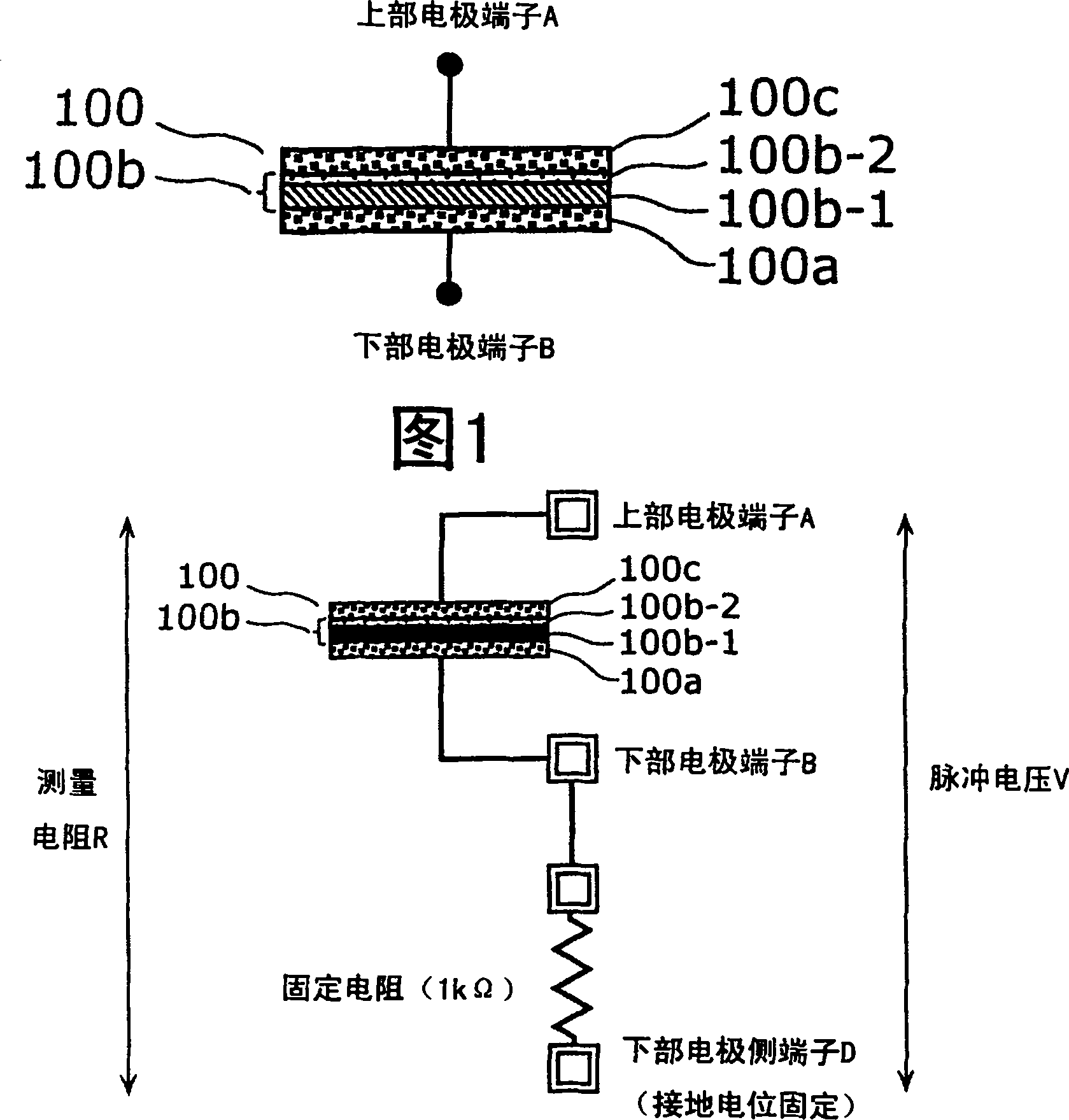

[0130] figure 1 It is a schematic diagram showing the basic structure of the variable resistance element used in this...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap