Carbon dioxide gas recovery apparatus

A carbon dioxide and gas recovery technology, applied in gas treatment, inorganic chemistry, through absorption, etc., can solve problems such as changing the temperature range, and achieve the effect of increasing absorption efficiency, small pressure loss, and high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

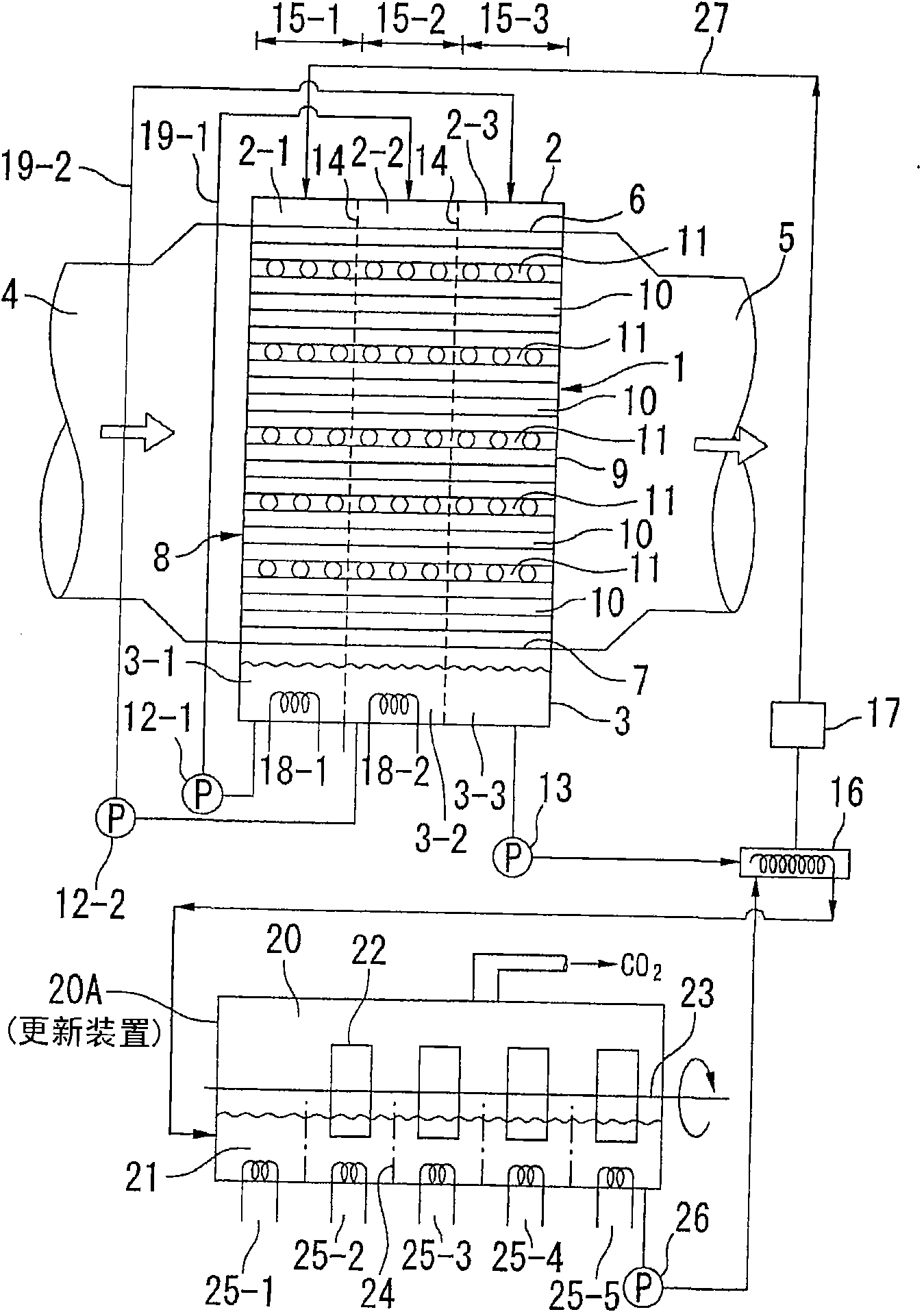

[0065] Hereinafter, embodiments of the present invention will be specifically described. That is to say, when the vertical cross-section of the carbon dioxide gas absorption chamber 1 is 10m x 10m and the flow velocity of the exhaust gas is 1.17Nm / sec, as the length of the carbon dioxide gas absorption chamber 1 corresponds to the change of the amount of absorbed carbon dioxide gas,

[0066] Amount of processed gas: 420,000Nm 3 / h;

[0067] When the concentration of recovered carbon dioxide gas in this case is 5%, the amount of recovered carbon dioxide gas is 21,000Nm 3 / h,

[0068] The weight of the carbon dioxide gas is 41.6t / h,

[0069] The amount of carbon dioxide gas absorbing solution required in this case is:

[0070] In the case of monoethanolamine, 57.6t / h,

[0071] In the case of potassium carbonate, 130.0t / h,

[0072] When the concentration of recovered carbon dioxide gas is gradually increased to 5%, 10%, 15% and 20%, since all you have to do is to extend the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com