Horizontal type spiral centrifuge

A horizontal screw and centrifuge technology, which is applied to centrifuges and centrifuges with rotating drums, etc., can solve the problems of operator inconvenience, damage to mud viscosity and density, and failure to achieve cleaning, etc., to achieve good cleaning effect, The mud pressure is stable and the vibration reduction effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

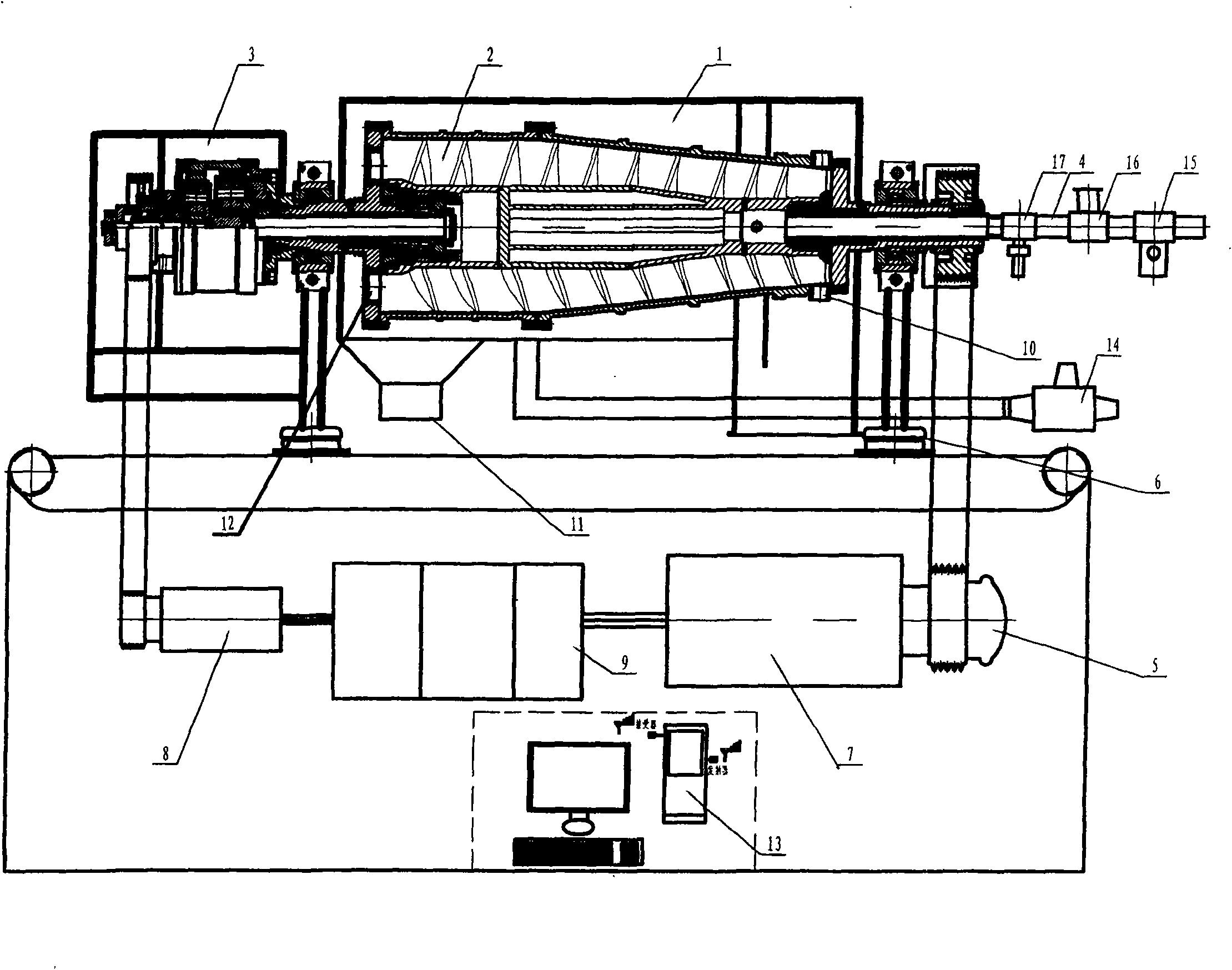

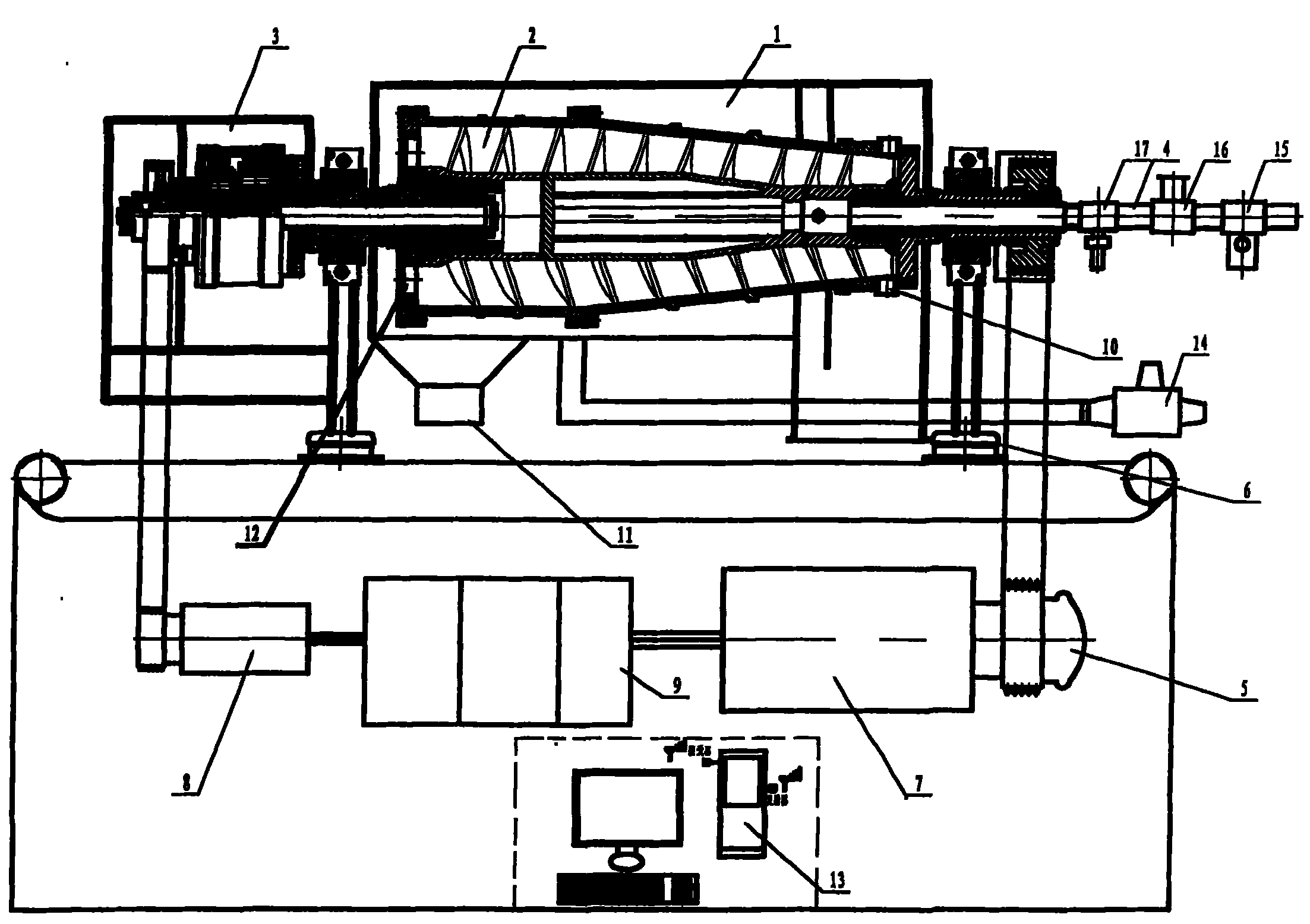

[0008] If the present invention is used in oil field drilling (as shown in the accompanying drawings), the open end of the constant pressure liquid flow valve 15 is connected with the screw pump, and the slurry inlet valve 16 is opened, and the frequency conversion control 9 is instructed to work through the wireless remote sensing device 13, The frequency conversion control 9 directs the main motor 7 and the auxiliary motor 8 to work respectively. The main motor 7 drives the drum 1 to rotate, and the auxiliary motor 8 drives the screw propeller 2 and the drum 1 to rotate at different speeds and in the same direction through the differential assembly 3 . When the screw pump pumps the drilling mud into the inner cavity of the drum 1, due to the pushing action of the blades of the screw propeller 2, the barite, stones and large-grained hard objects in the mud are discharged from the slag discharge port 10. After being discharged, the remaining mud that meets the drilling pipe lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com