Method for preparing high-concentration emulsion from modified nano titanium dioxide powder

A nano-titanium dioxide, concentrated emulsion technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of preparing high-concentration emulsion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Get 1 gram of nano-titanium dioxide powder with a particle size of 24nm, under magnetic stirring at 1000rmp, disperse in a mixed solution of 50 ml of chloroform and 50 ml of oleic acid, and react for 2 hours at 30 degrees Celsius;

[0020] Add 100 ml of methanol to stop the reaction and precipitate, centrifuge the flocculated precipitate at 20,000 rpm, remove the supernatant to obtain a light blue gel-like modified nano-titanium dioxide, then add 20 ml of chloroform to rinse for 20 minutes, and centrifuge again at high speed; add 50 Wash with 1 ml of methanol, centrifuge at a high speed, and wash with methanol for 3 times, and place the obtained gel-like product in a vacuum oven, dry at 120 degrees Celsius for 24 hours, take it out and grind it lightly to obtain the modified nano-titanium dioxide powder.

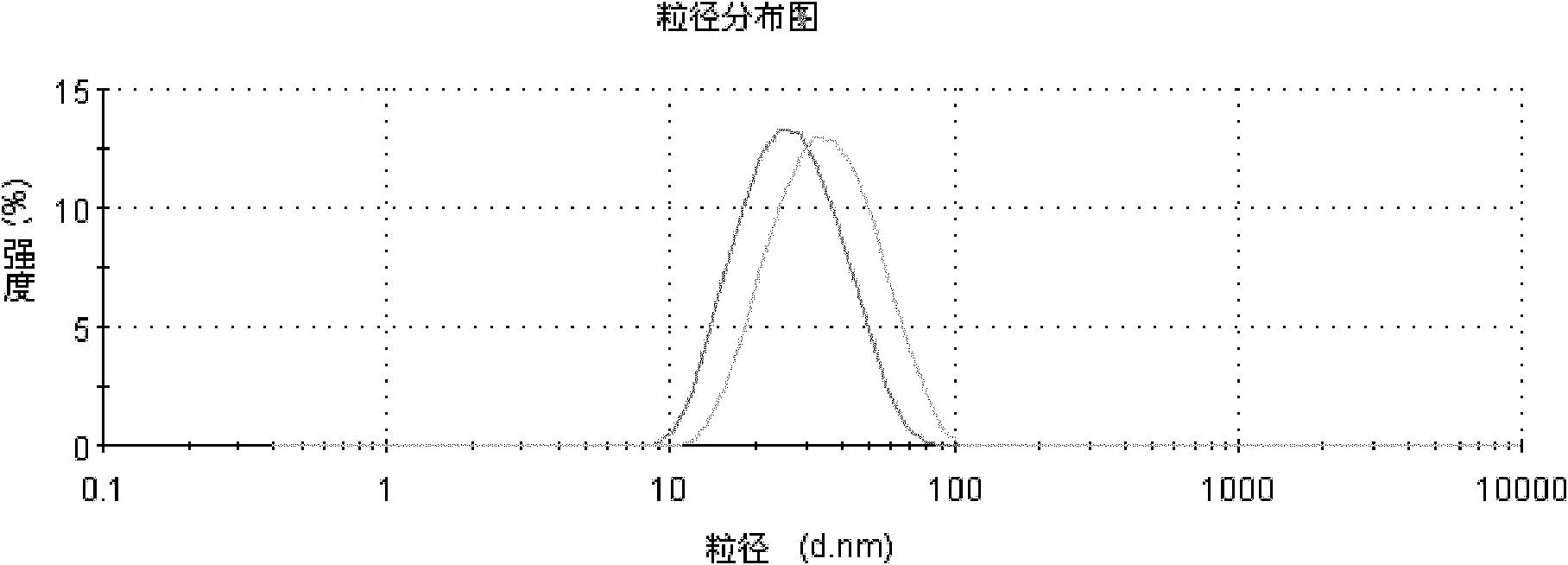

[0021] Get 0.3 g of the prepared modified nano-titanium dioxide powder, add it to 30 milliliters of xylene, ultrasonically disperse it for 15 minutes (60KHz, power 200...

Embodiment 2

[0025] Take 1 gram of nano-titanium dioxide powder with a particle size of 22nm, disperse it in a mixed solution of 30 ml of chloroform and 70 ml of oleic acid under magnetic stirring at 1200 rpm, and react at 25 degrees Celsius for 5 hours.

[0026] Add 100 ml of methanol to stop the reaction and precipitate, centrifuge the flocculated precipitate at 20,000 rpm, remove the supernatant to obtain a light blue gel-like modified nano-titanium dioxide, then add 20 ml of chloroform to rinse for 20 minutes, and centrifuge again at high speed; add 50 Washing with one milliliter of methanol, high-speed centrifugation, and repeated washing with methanol for 5 times, the obtained gel-like product was placed in a vacuum oven, dried at 120 degrees Celsius for 24 hours, taken out and lightly ground to obtain the modified nano-titanium dioxide powder.

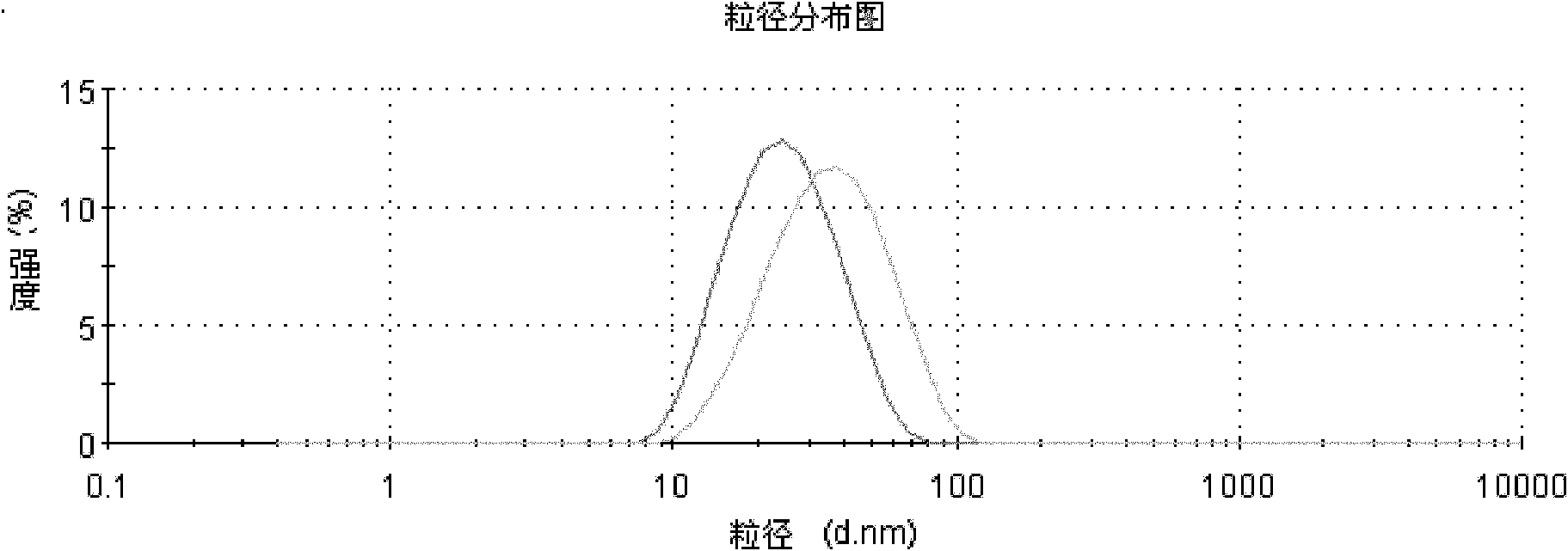

[0027] Get the modified nano-titanium dioxide powder that 0.5 gram makes, add in 50 milliliters of styrenes, high-speed stirring 15 minutes ...

Embodiment 3

[0030] Take 1 gram of nano-titanium dioxide powder with a particle size of 25.4nm, and disperse it in a mixed solution of 40 milliliters of chloroform and 60 milliliters of oleic acid under magnetic stirring at 1000 rpm, and react at 25 degrees Celsius for 4 hours.

[0031] Add 100 ml of methanol to stop the reaction and precipitate, centrifuge the flocculated precipitate at 20,000 rpm, remove the supernatant to obtain a light blue gel-like modified nano-titanium dioxide, then add 20 ml of chloroform to rinse for 20 minutes, and centrifuge again at high speed; add 50 Wash with 1 ml of methanol, centrifuge at high speed, and repeat the washing with methanol for 5 times, place the obtained gel-like product in a vacuum oven, dry at 120 degrees Celsius for 24 hours, take it out and grind it lightly to obtain the modified nano-titanium dioxide powder.

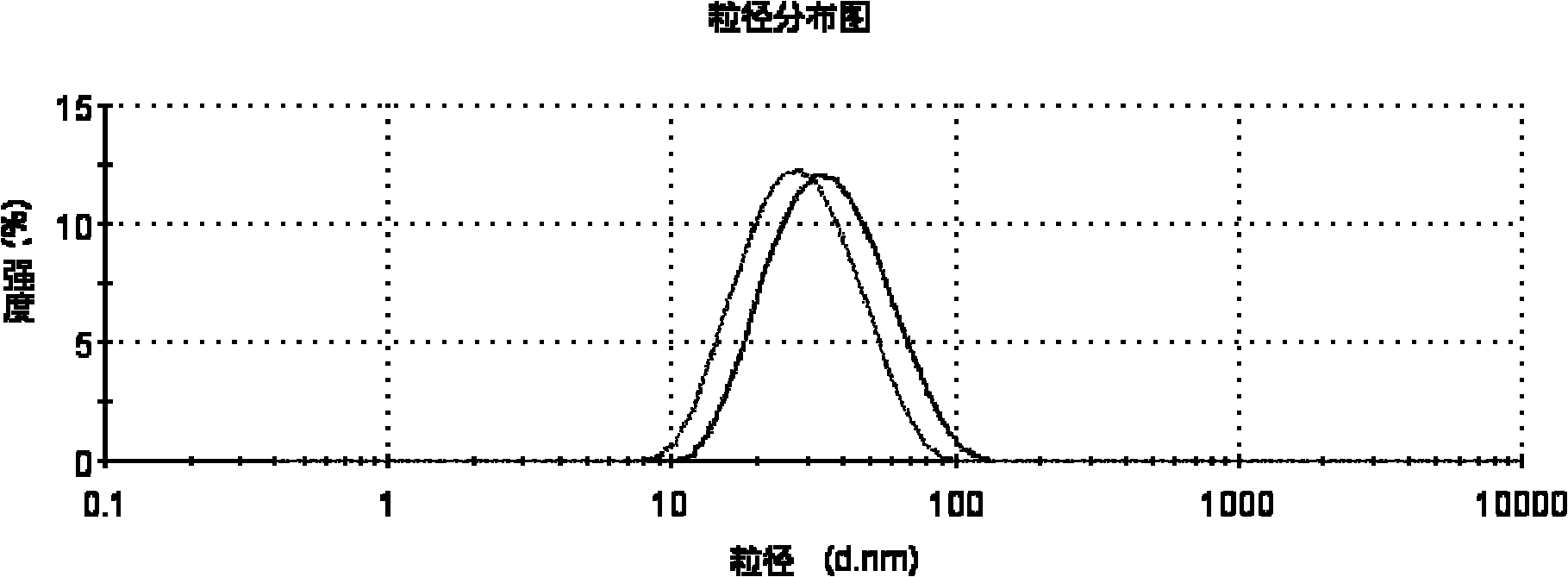

[0032] Get 0.5g of modified nano-titanium dioxide powder, add 25ml of styrene and 25ml of divinylbenzene in the mixed oil phase, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com