Method for preparing amphiphilic nano silica powder and method for preparing Pickering emulsion using same

A nano-silica and amphiphilic technology, which is applied in the manufacture of silica, silicon oxide, and nanostructures, can solve the problems of time-consuming, difficult operation, and inability to form Pickering emulsions, etc., and achieve the effect of short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

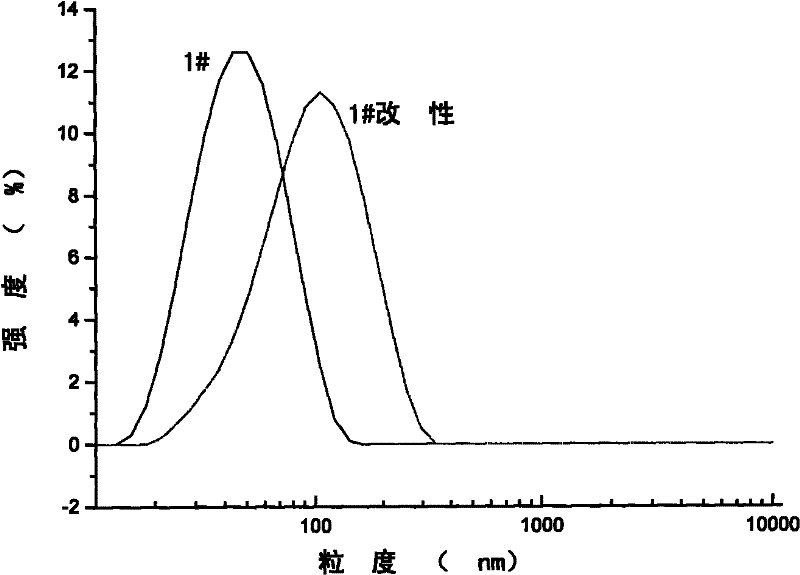

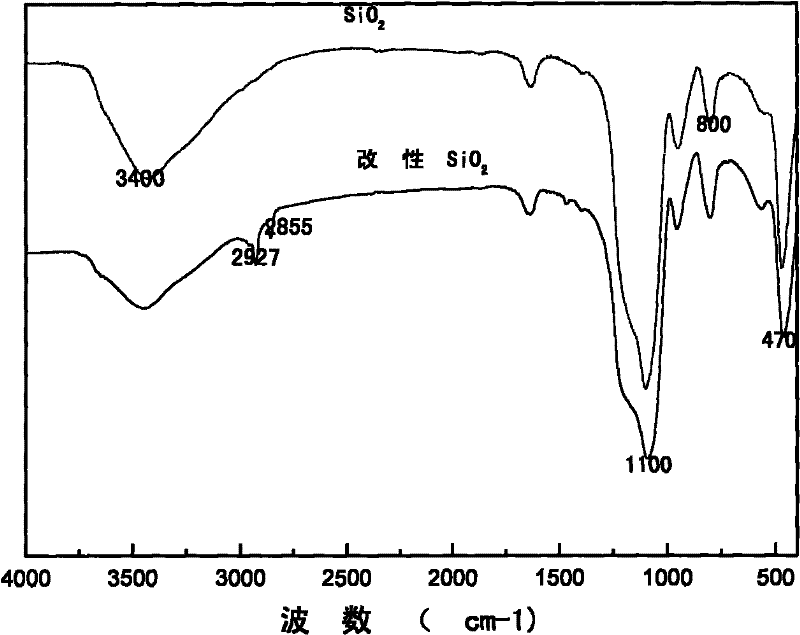

[0022] Example 1: Take 20mL tetraethyl orthosilicate and 200mL methanol, vibrate in an ultrasonic cleaner with a frequency of 40KHz and a power of 250W for 5min; take 40mL ammonia water with a concentration of 25% and add it to 400mL methanol, stir it evenly and pour it into the In the methanol solution of tetraethyl orthosilicate oscillated by ultrasound, continue to react under ultrasound for 3 hours. The whole process is cooled by circulating water, and the water temperature is kept at 15°C. Finally, light blue nano-SiO can be obtained. 2 Dispersions. After detection by laser particle size analyzer, Z-Average (d.nm): 42.8nm, particle size polydispersity index (PDI) is 0.149, see the test results figure 1 . The dispersion liquid is stable in nature, and the particle size basically does not change after being stored at room temperature for more than 3 months.

[0023] Take the above nano-SiO 2 Dispersion liquid 100mL, add glacial acetic acid dropwise under pH meter monitor...

Embodiment 2

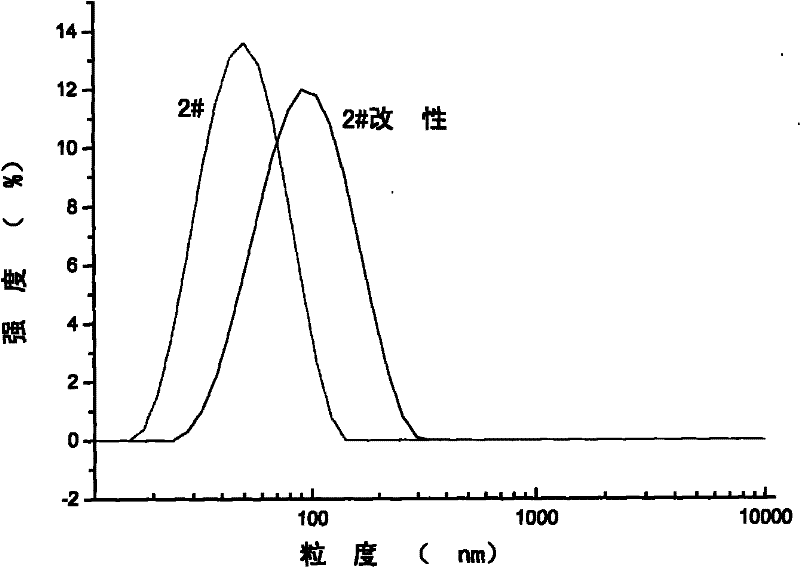

[0026] Example 2: Take 10mL tetraethyl orthosilicate and 100mL methanol, and vibrate in an ultrasonic cleaner with a frequency of 30KHz and a power of 300W for 6min; take 20mL of ammonia water with a concentration of 26% and add it to 200mL of methanol, stir it evenly, and pour it into the In the methanol solution of tetraethyl orthosilicate oscillated by ultrasonic waves, continue to react under ultrasonic for 2 hours. The whole process is cooled by circulating water, and the water temperature is kept at 18°C. Finally, light blue nano-SiO can be obtained. 2 Dispersions. After detection by laser particle size analyzer, Z-Average (d.nm): 44.1nm, particle size polydispersity index (PDI) is 0.157, see figure 2 .

[0027] Take the above nano-SiO 2 Dispersion liquid 100mL, add glacial acetic acid dropwise under pH meter monitoring and magnetic stirring, adjust the pH value of the dispersion liquid to 7.3, add 0.15mL long-chain alkyltrimethoxysilane (WD-10) after ultrasonic dispers...

Embodiment 3

[0030] Example 3: Take 30mL tetraethyl orthosilicate and 300mL methanol, and vibrate in an ultrasonic cleaner with a frequency of 60KHz and a power of 200W for 8min; take 60mL of ammonia water with a concentration of 27% and add it to 600mL of methanol, stir it evenly, and pour it into the In the methanol solution of tetraethyl orthosilicate oscillated by ultrasound, continue to react for 5 hours under ultrasound. The whole process is cooled by circulating water, and the water temperature is kept at 21°C. Finally, light blue nano-SiO can be obtained. 2 Dispersions. After detection by laser particle size analyzer, Z-Average (d.nm): 43.2nm, particle size polydispersity index (PDI) is 0.173, see Figure 4 .

[0031] Take the above nano-SiO 2 Dispersion liquid 100mL, add glacial acetic acid dropwise under pH meter monitoring and magnetic stirring, adjust the pH value of the dispersion liquid to 7.5, add 0.09mL long-chain alkyltrimethoxysilane (WD-10) after ultrasonic dispersion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com