Control method of combustion engine using dimethyl ether and high-octane rating fuel

A high-octane, dimethyl ether technology, applied in fuel injection control, engine control, internal combustion piston engines, etc., can solve the problems of reducing, consuming part of power, increasing fuel consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

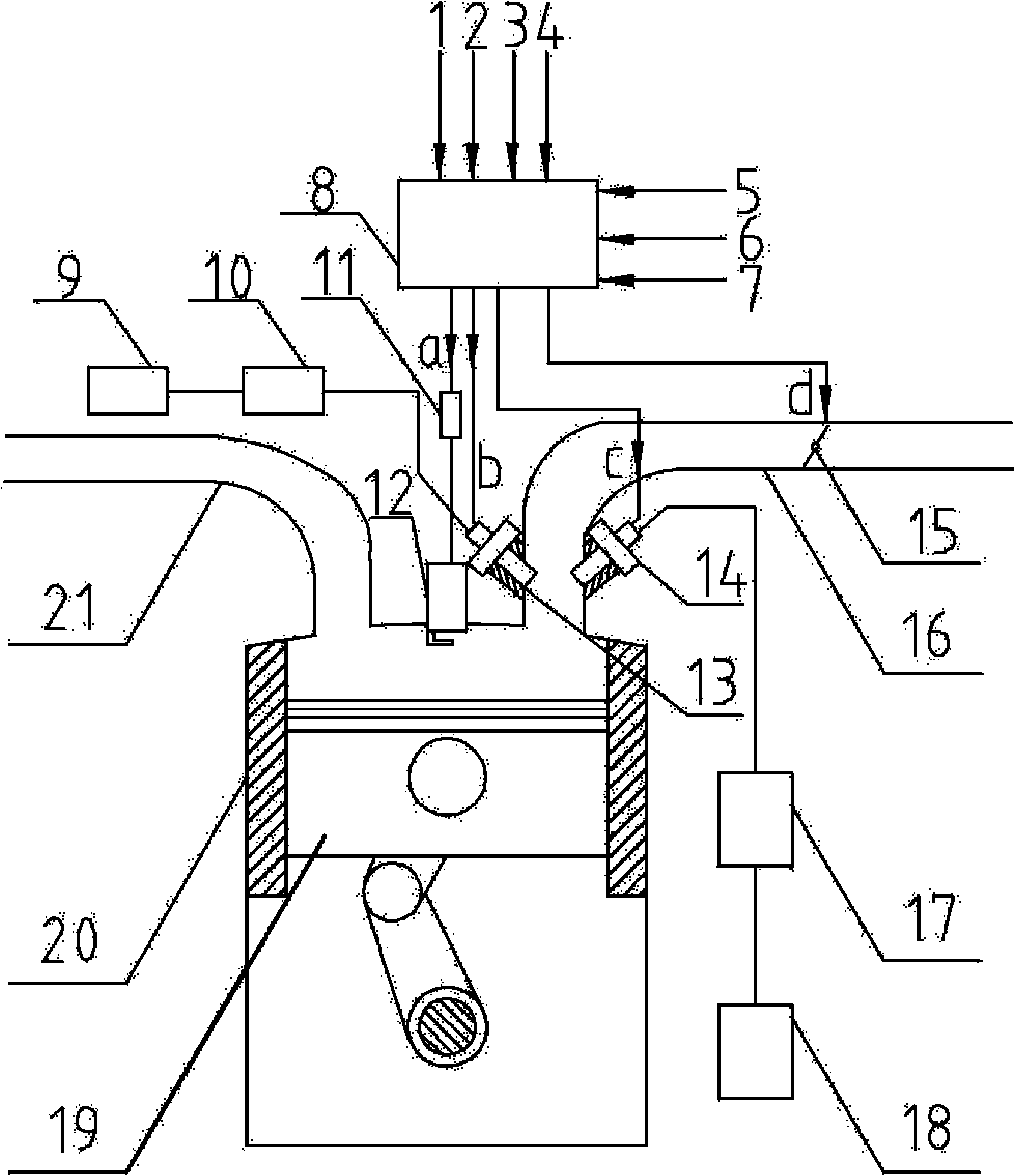

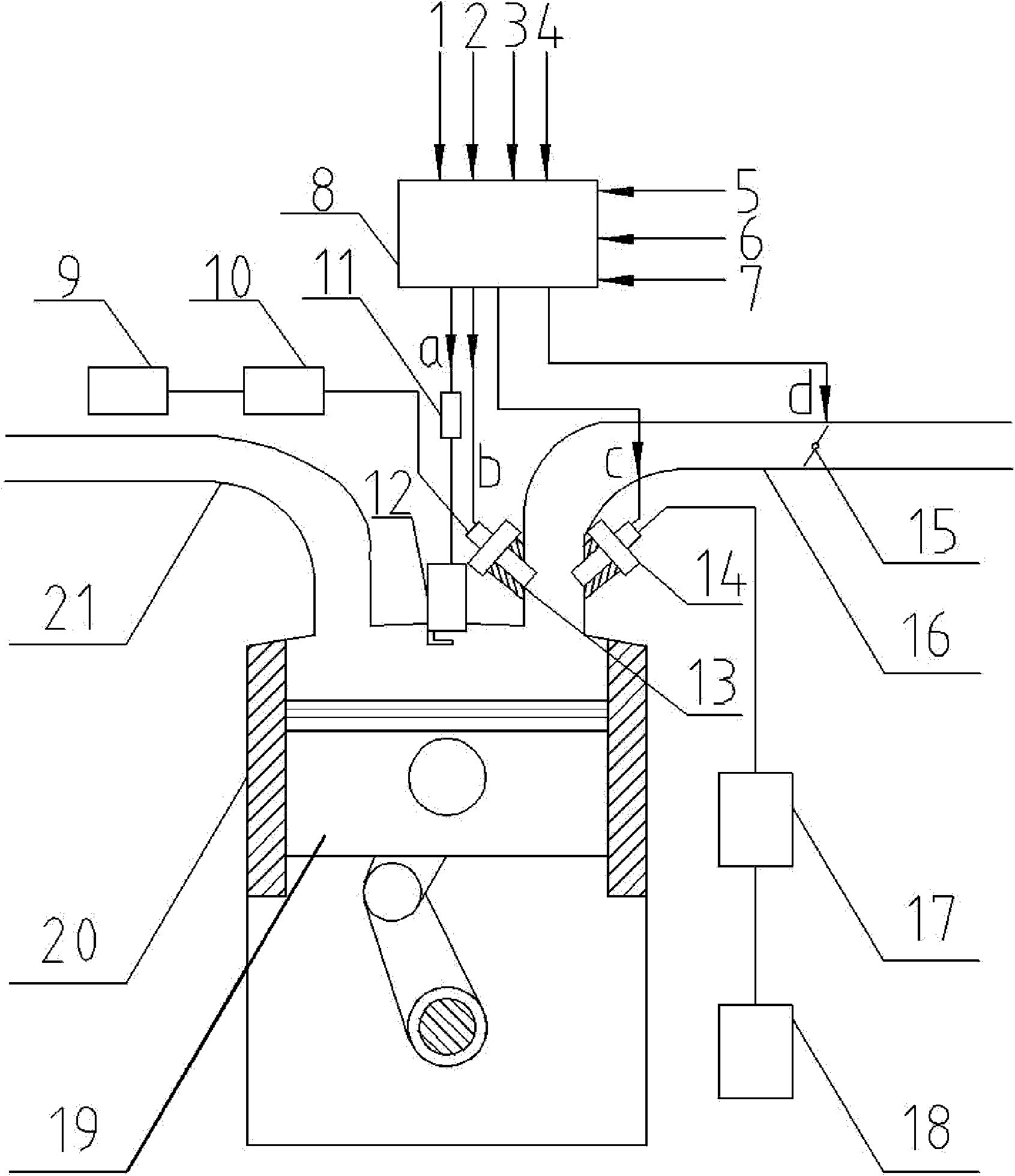

[0032] This embodiment has done following experiment to various working conditions:

[0033] The experimental internal combustion engine is an in-line 4-cylinder 1.6L EFI gasoline engine, according to figure 1 Shown is a combustion-mode internal combustion engine retrofitted to DME and high-octane fuels in-situ for mixed loads. The high-octane fuel used in the experiment is methanol CH 3 . Use a Horiba-7100DEGR emission analyzer produced by Horiba Co., Ltd. to measure HC, CO and NO in each operating condition of the internal combustion engine x emission.

[0034] 1. Start experiment

[0035]Start the engine, and the mixed fuel electronic control unit 8 determines the injection amount of DME and the mixture gas concentration according to the temperature indicated by the cooling water temperature signal 2 of the cooling water temperature sensor. The experimental results show that when the cooling water temperature signal 2 is 0.3V, the cooling water temperature is 10-12°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com