Module combined type exhaust-heat boiler

A waste heat boiler and module combination technology, applied in the field of boilers, can solve the problems of large floor space, difficult maintenance, complex structure of waste heat recovery and utilization devices and waste gas treatment and utilization devices, etc., to reduce the frequency of failures, facilitate installation, disassembly and adjustment, Improve the effect of difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

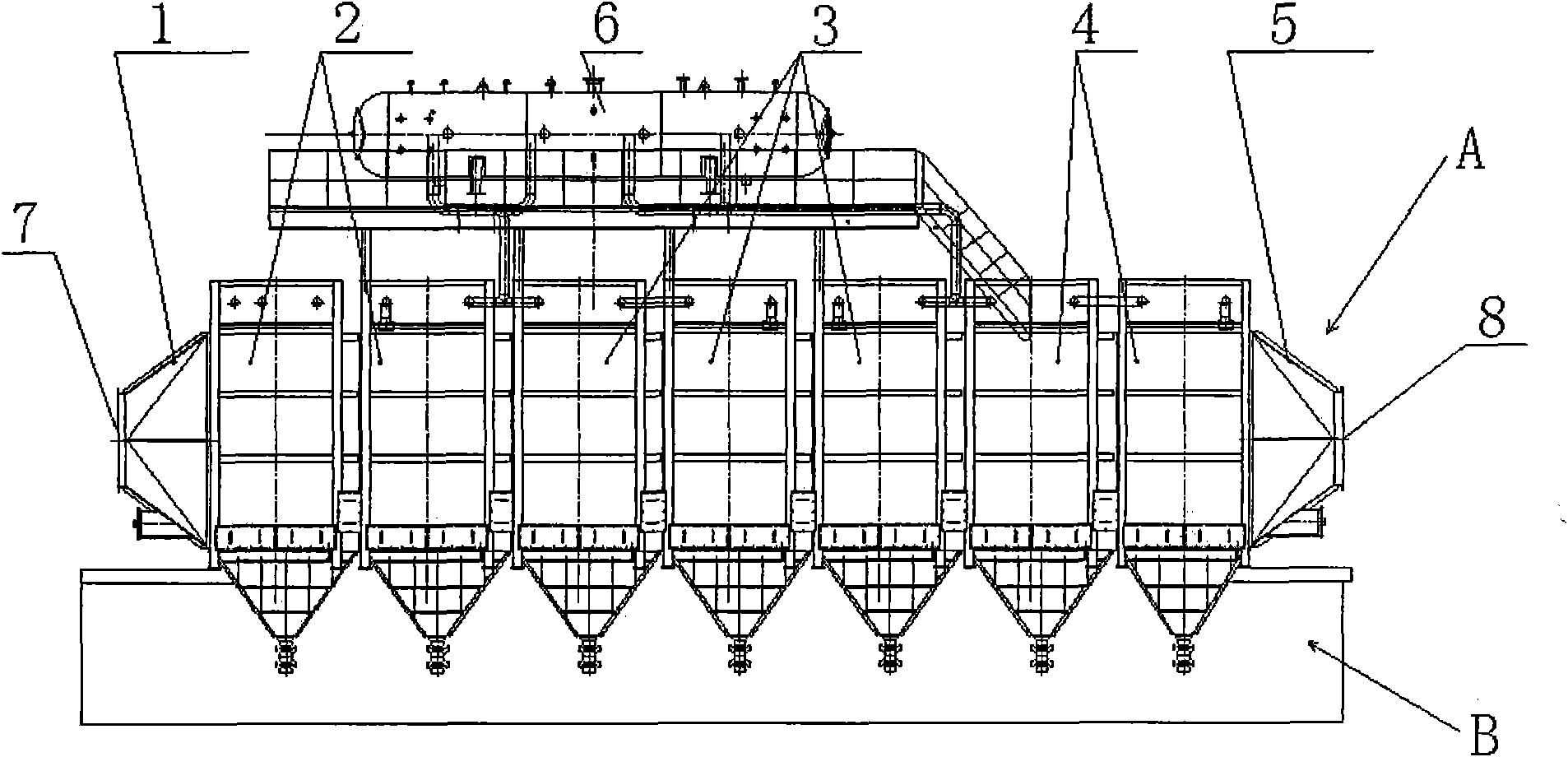

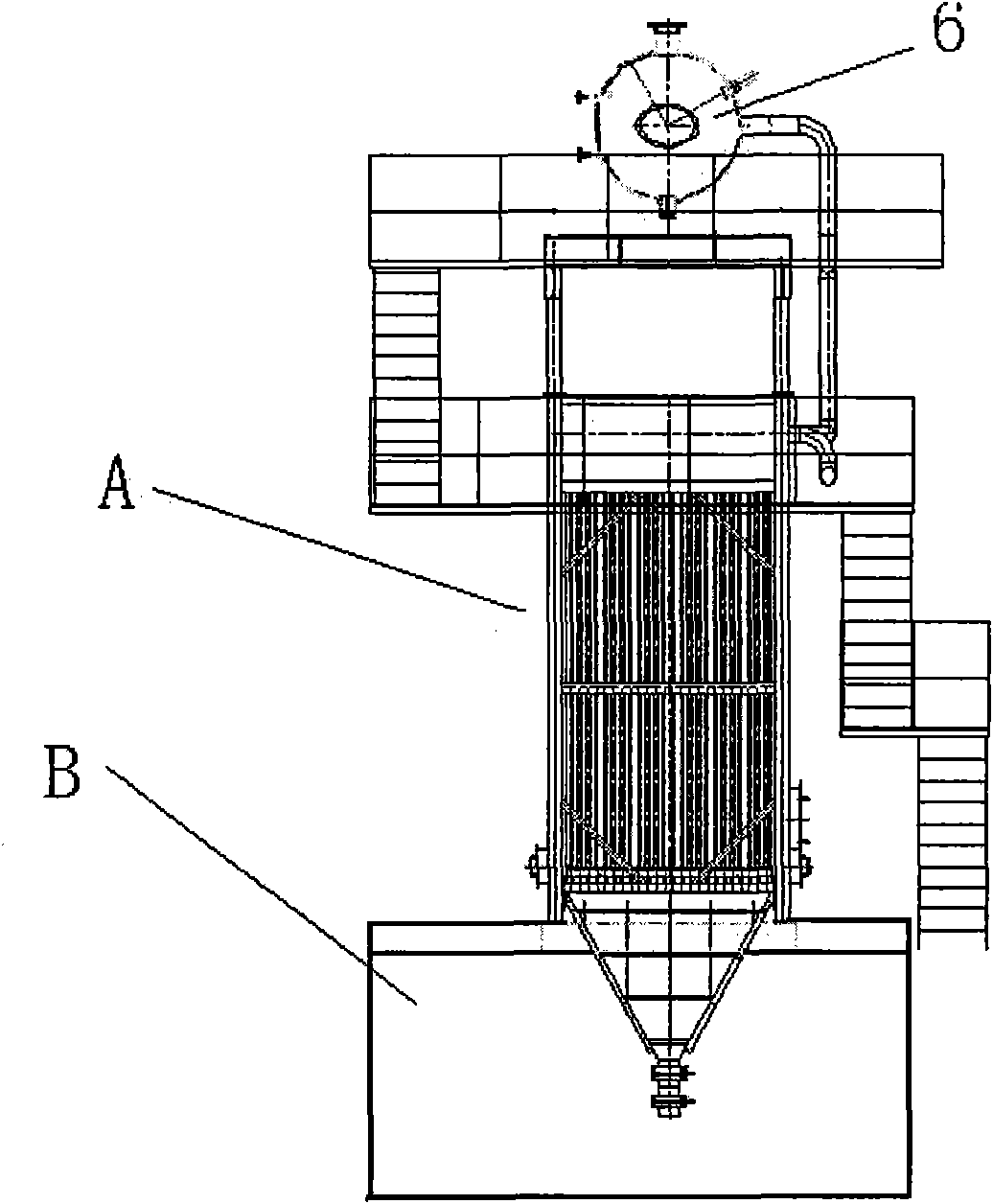

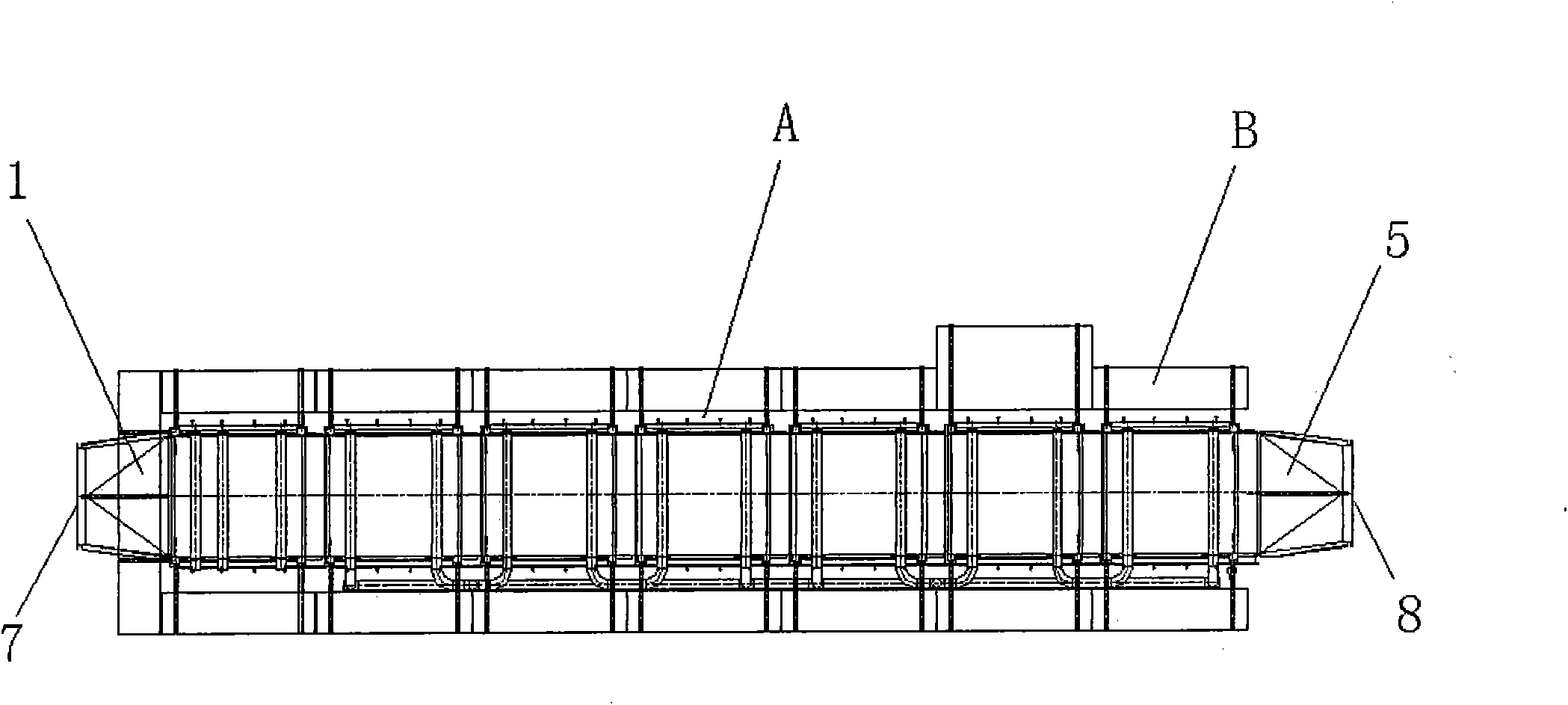

[0039] like figure 1 , figure 2 and image 3As shown, the modular combined waste heat boiler of the present invention is provided with a flue gas inlet smoke box 1, a superheater module group 2, an evaporator module group 3, a preheater module group 4 and a flue gas outlet smoke box 5 in sequence from left to right In addition, a steam drum assembly 6 is arranged on the upper part of the superheater module group, the evaporator module group and the preheater module group to form a modular waste heat boiler of the present invention.

[0040] The module type and the way of assembling in embodiment 1 are as follows figure 1 As shown, it is specifically a flue gas inlet smoke box 1, the number of superheaters in the superheater module group 2 is 2, the number of evaporators in the evaporator module group 3 is 3, and the number of preheaters in the preheater module group 4 The number of heaters is 2, plus a flue gas outlet smoke box 5, and a steam drum assembly 6 connected to i...

Embodiment 2

[0042] specific structure reference figure 1 , figure 2 and image 3 , the difference lies in the number of components in each module group, specifically: the number of superheaters in superheater module group 2 is 1, the number of evaporators in evaporator module group 3 is 2, and the number of evaporators in preheater module group 4 The number of preheaters is 1. In addition, because the number of components is small, a smaller steam drum assembly can be used. The installation settings of the remaining flue gas inlet smoke box 1 and flue gas outlet smoke box 5 are the same as in Example 1. , the installation method of the modular waste heat boiler in this embodiment is the same as that in Embodiment 1, but due to the small number of components, the floor area is small, and it is suitable for the waste heat utilization field of small boilers.

Embodiment 3

[0044] specific structure reference figure 1 , figure 2 and image 3 , the difference lies in the number of components in each module group, specifically: the number of superheaters in superheater module group 2 is 3, the number of evaporators in evaporator module group 3 is 6, and the number of preheater module group 4 The number of preheaters is 3. In addition, due to the large number of components, a larger steam drum assembly is required. The installation settings of the remaining flue gas inlet smoke box 1 and flue gas outlet smoke box 5 are the same as in Example 1. The installation method of the modular combined waste heat boiler of this embodiment is the same as that of Embodiment 1, but due to the large number of components, it occupies a larger area, but it is still smaller than the integrated waste heat boiler in the prior art, and is suitable for large boilers waste heat utilization field.

[0045] In order to simplify the installation of the modular combined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com