Clock system standard source and work method

A clock system and working method technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve the problems of large quantity, high cost, time-consuming and laborious, etc., and achieve the effect of low equipment cost, low cost, and convenient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

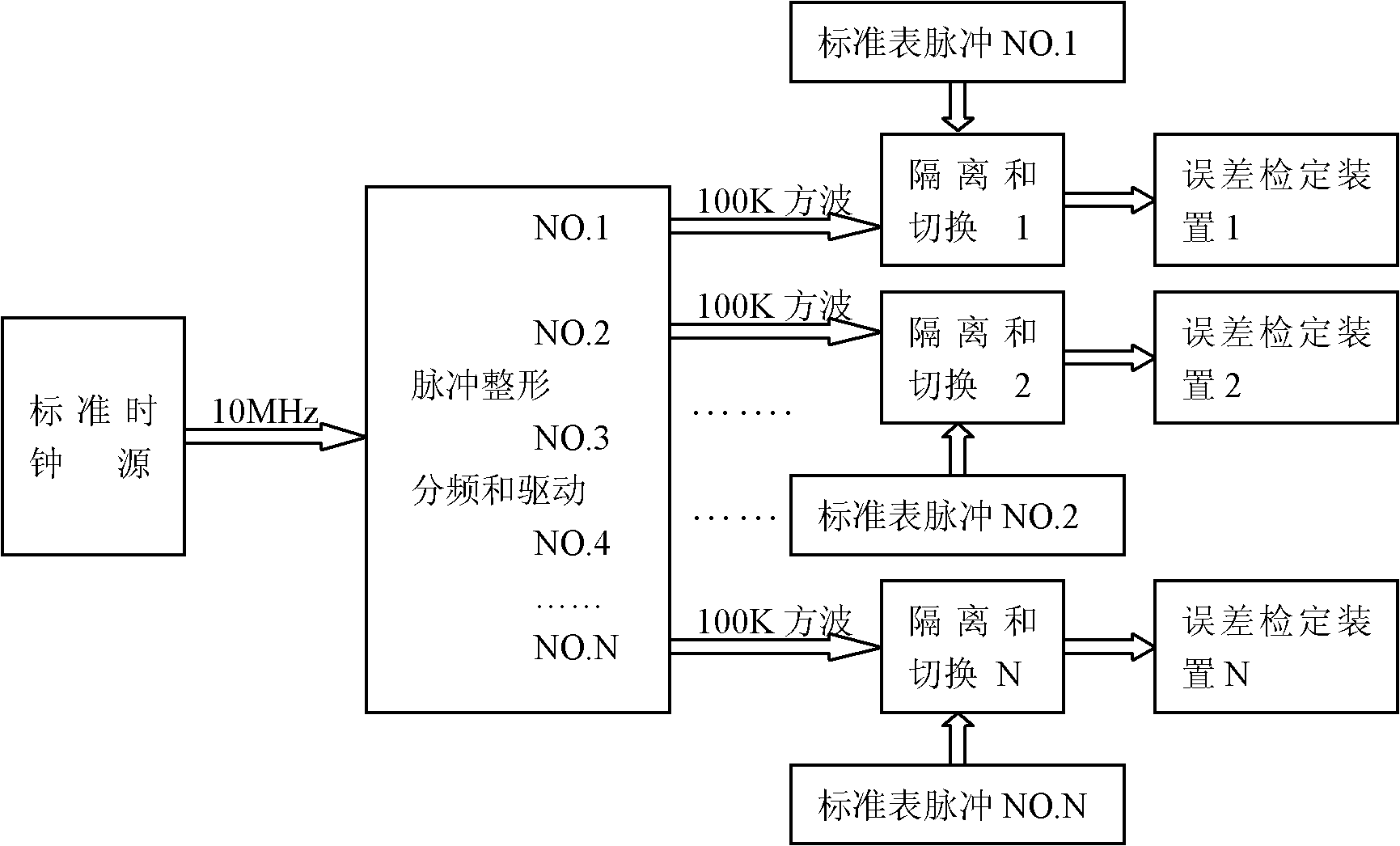

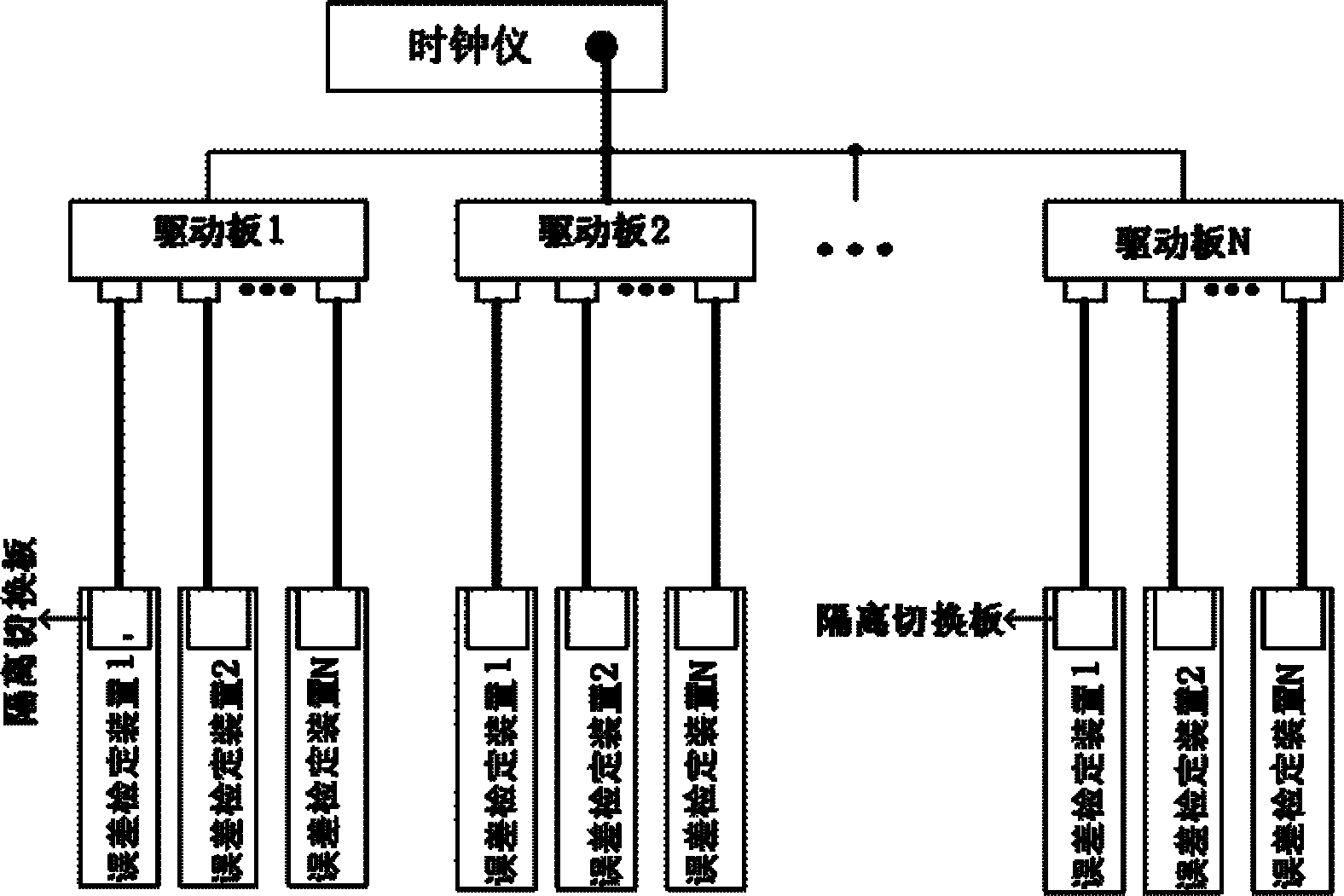

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 2 As shown, the present invention includes a clock instrument, a drive board connected to the clock instrument for frequency division and shaping of high-frequency pulses, a plurality of isolation switch boards connected to the drive board for electrical isolation, and an output port of the isolation switch board It is connected with the error checking device to send the divided frequency clock signal to the error checking device after isolation. The number of isolation switching boards and error verification devices matches the number of detection stations. The clock instrument is connected to a plurality of driving boards, and a driving board is connected to a plurality of isolation switching boards. The wiring between the clock instrument and the driver board adopts a bus plus star wiring method, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com