Automatic control system for surface process treatment

An automatic control system and process technology, applied in the direction of comprehensive factory control, digital control, electrical program control, etc., can solve the problem of damage to precision objects, and achieve the effects of reducing damage rate, convenient operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention clear and easy to understand, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

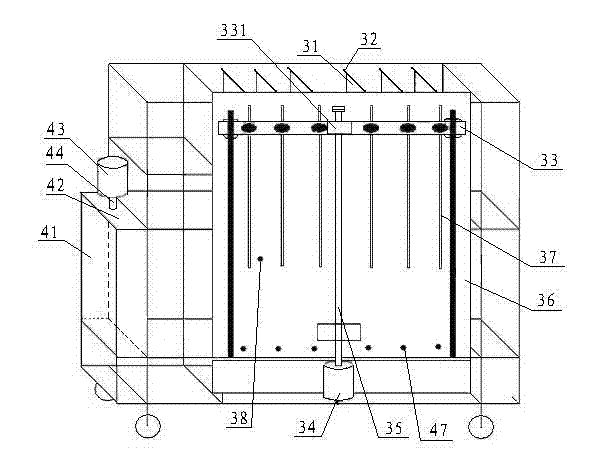

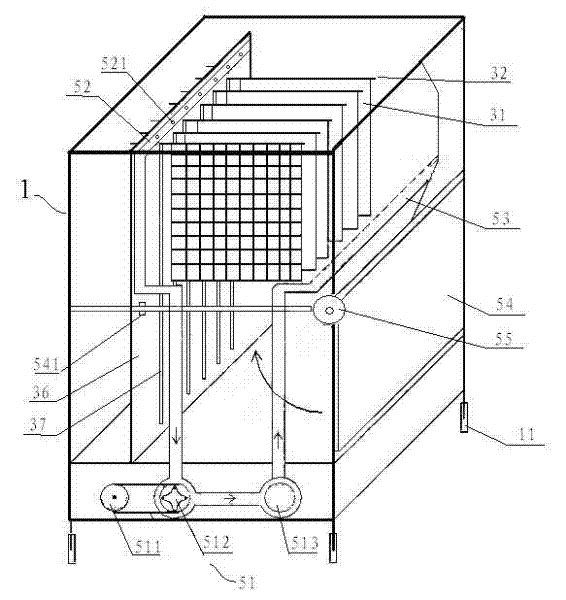

[0024] combine Figure 1 to Figure 5 As shown, an automatic control system for surface process treatment of the present invention includes a cabinet body 1 and a control unit 2. The control unit 2 includes an operation panel that can set the number of parts boxes, heat treatment process curves, and switch control motors. MCU or other software modules in the art realize related automatic control functions. The system also includes a parts box control component 3, a material tank control component 4, and a heat treatment control component 5, wherein:

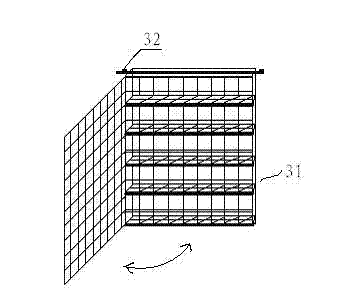

[0025] Parts box control assembly 3 comprises parts box 31, hanging bar 32, transverse arm 33, Y direction motor 34, Y direction screw mandrel 35, and parts box 31 is the multi-layer mesh box body that stainless steel wire welds,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com