Machining load control system based on instruction sequence optimization

A technology of command sequence and load control, applied in electrical program control, digital control and other directions, can solve the problems of large manual participation, high cost and poor intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

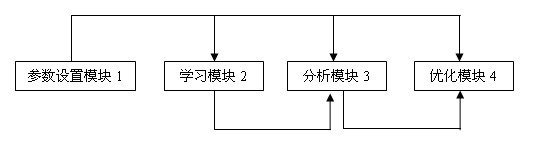

Method used

Image

Examples

Embodiment Construction

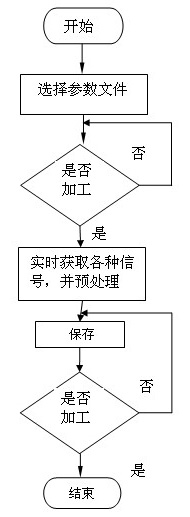

[0021] The system of the present invention first learns the working condition characteristics and accuracy of a certain part processed in large batches, wherein the working condition information includes cutting load and vibration. During the learning process, the learning module embedded in the numerical control system needs to obtain the corresponding processing instructions in real time. Collect the processing load and vibration corresponding to the instruction running, and at the same time obtain online or offline (manually input) the machining accuracy of the geometric position of the relevant parts, and the system automatically determines the processing instruction code corresponding to the geometric position of the part.

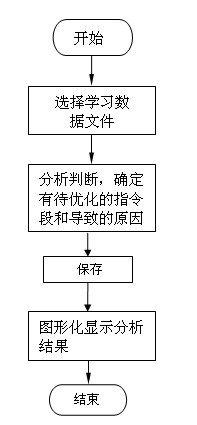

[0022] Then, analyze the error between the precision of the machined parts and the actual machining precision and the vibration characteristics, find the problematic machining position, determine the reasons that affect the precision and cause the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com