Modeling method of steel mill production scheduling system based on Agent and Agent UML (Unified Modeling Language)

A production scheduling and system modeling technology, applied in the field of complex system modeling, can solve the problems of not meeting the requirements of system design, not strong object autonomy, and not being able to realize system parallelism well, so as to achieve enhanced dynamics, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

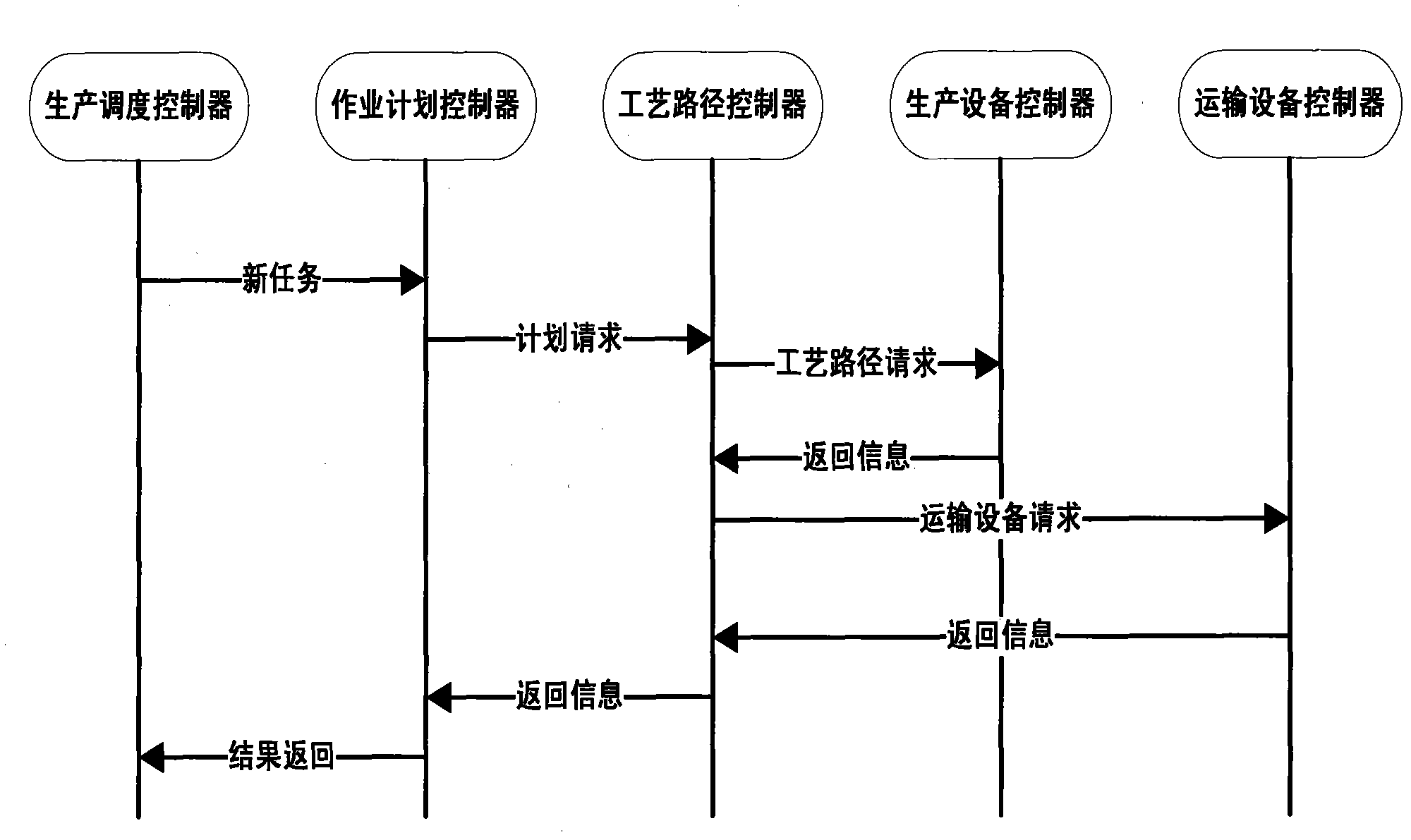

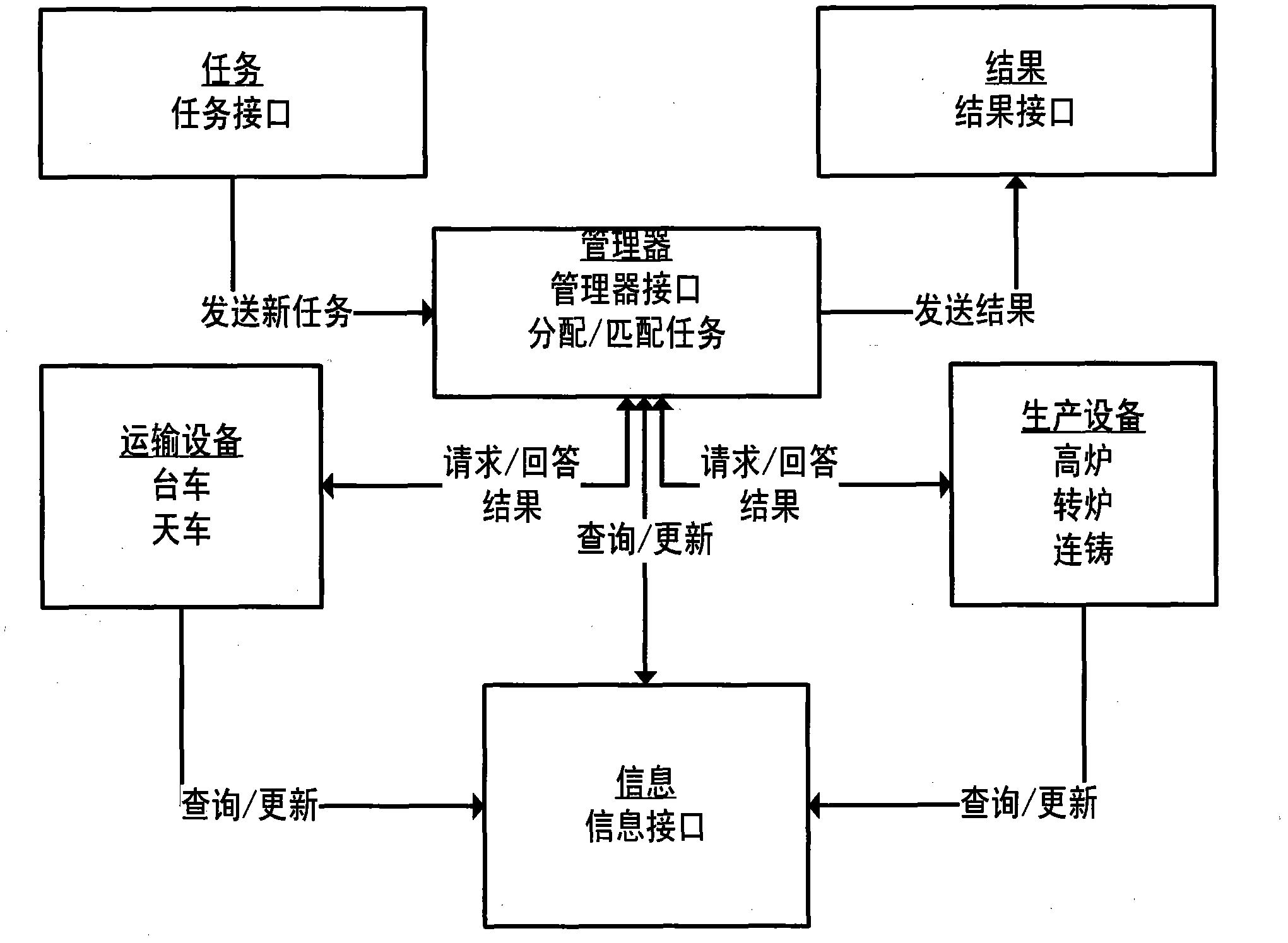

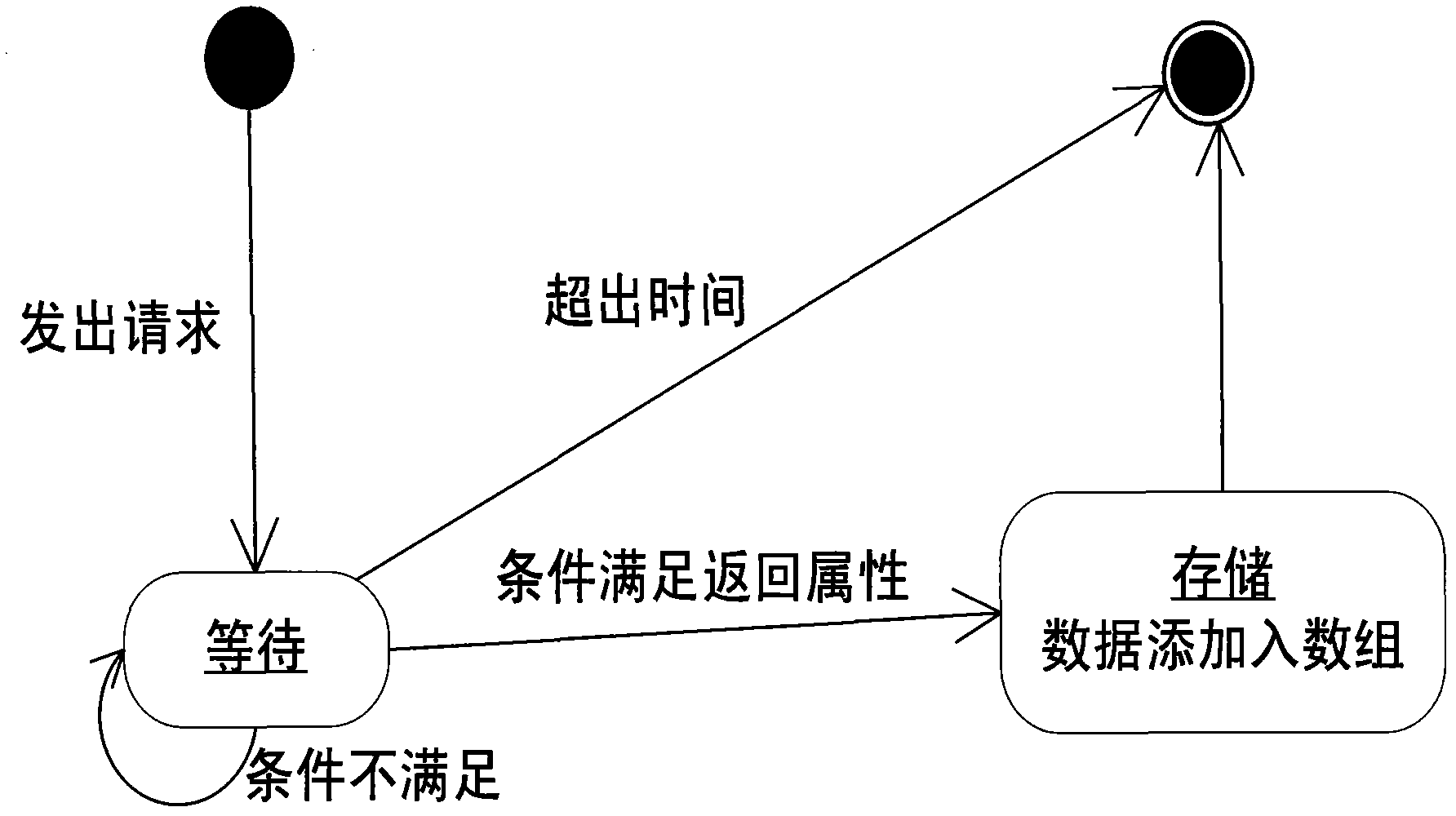

[0030] Example 1: Using the modeling method of the steel mill production scheduling system based on Agent and Agent UML, for the steel mill production scheduling system, the overall goal of the steel mill production scheduling system is to complete the production scheduling task in real time with high efficiency and low cost. In order to better achieve the system goals, the overall goal can be decomposed to obtain the following sub-goals: ① Operation plan management: formulate operation plans according to the higher-level production tasks; ② Process management: According to the attributes of the operation, determine the process path of the product; ③ Equipment management: realize the dynamic scheduling, allocation and management of equipment, record the status and operation of equipment; ④ data analysis management: realize the collection, analysis and arrangement of data in the production process, dynamic update, and timely feedback to production scheduling management; ⑤ materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com