Manufacturing method of ceramic spraying part

A manufacturing method and component technology, which is applied in the field of manufacturing ceramic spraying components, can solve problems such as health hazards for operators, toxicity and flammability, environmental pollution, etc., and achieve the effect of eliminating adverse effects and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

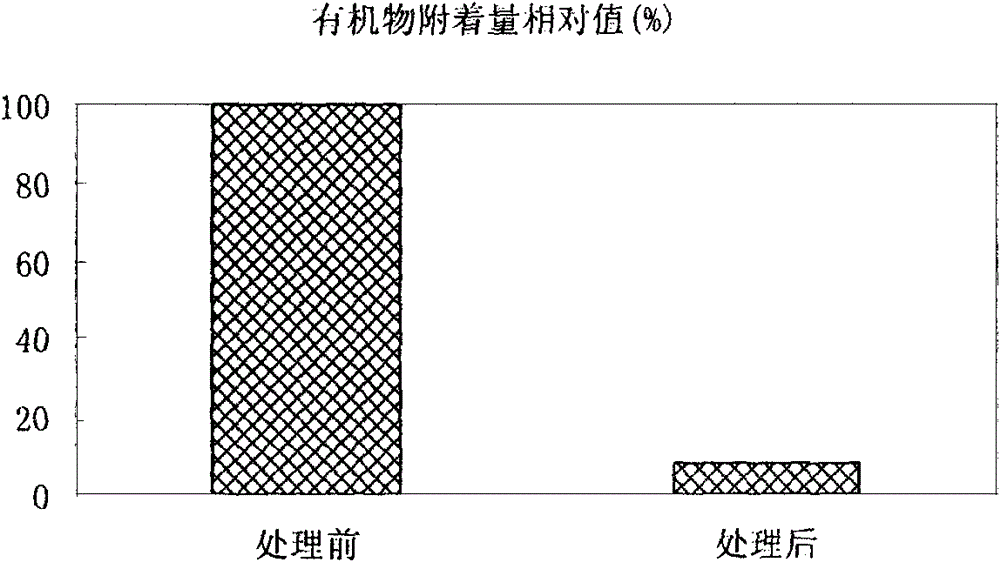

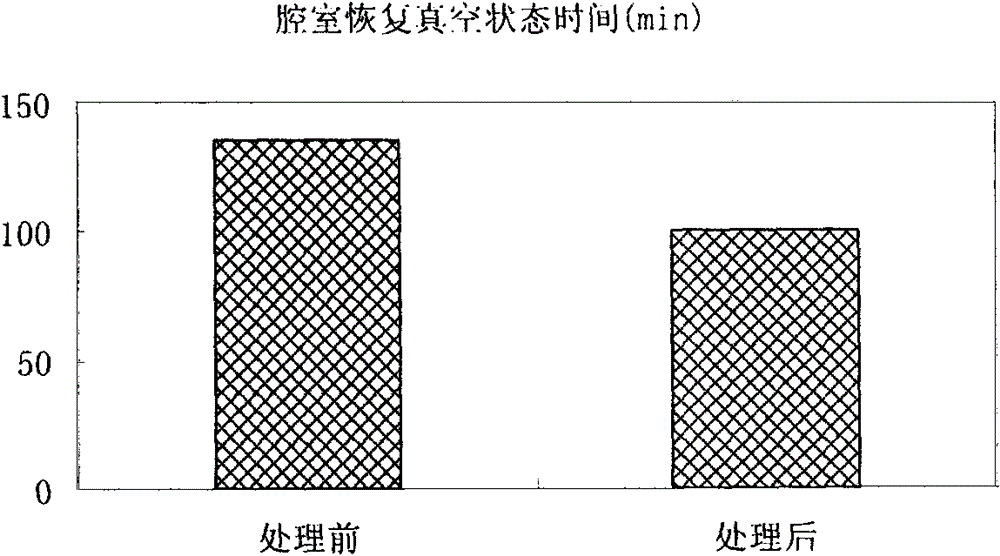

[0023] The present invention aims to provide a method for manufacturing ceramic sprayed parts, which can effectively remove organic matter on the surface of the ceramic layer, so that the surface of the ceramic layer can obtain sufficient hydrophobicity during hydration treatment, and at the same time avoid pollution to the environment.

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

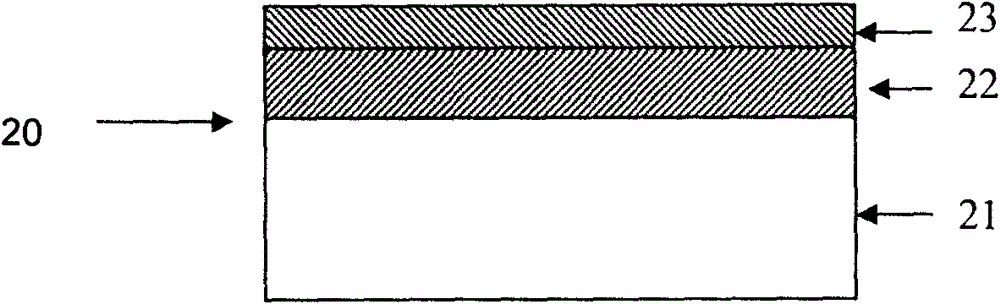

[0025] Such as figure 1 Shown, ceramic spraying part manufacturing method of the present invention comprises steps:

[0026] S10, processing the surface of the substrate to form a rough surface;

[0027] The surface of the substrate is sandblasted with particles such as corundum and stainless steel to form an uneven surface on the surface of the substrate. Even if the surface of the substrate has a certain roughness, the roughness is preferably Ra10-20 μm. Forming an uneven surface with a roughness of Ra10-20μm on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com