Double water-cooling and demoulding mechanism of plastic bottle cap mould

A demolding mechanism and double water cooling technology, applied in the field of plastic bottle cap molds, can solve the problems of affecting the cooling conduction speed, affecting the processing quality of the bottle cap, and the unevenness of the plane of the bottle cap. The effect of the flat surface of the cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

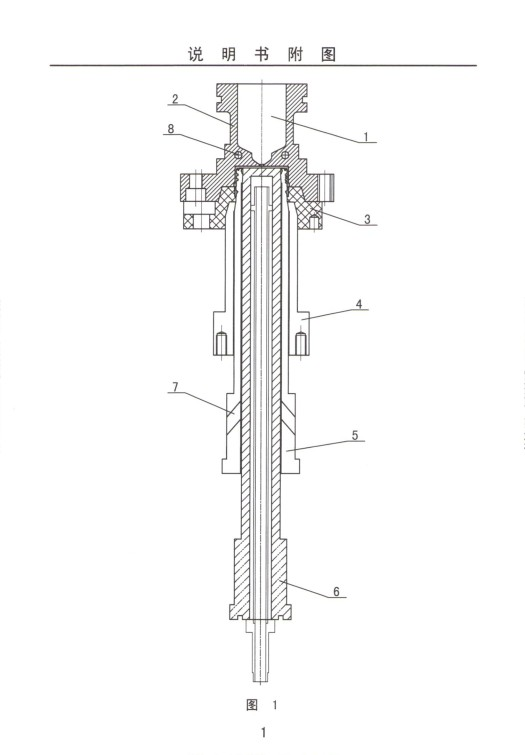

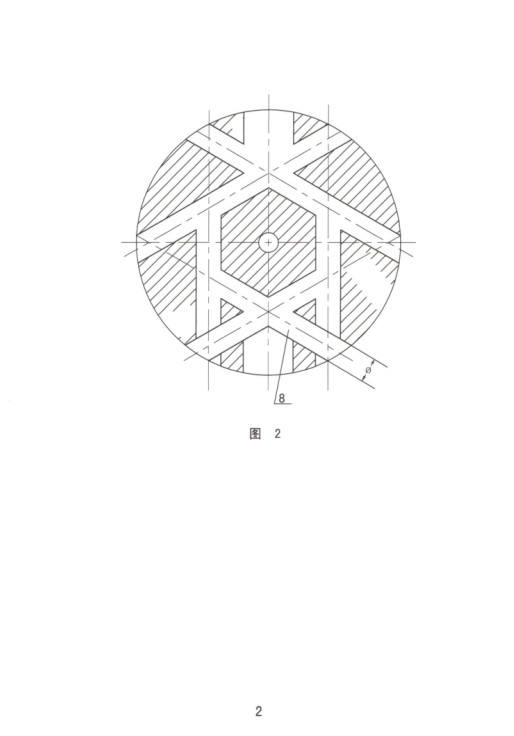

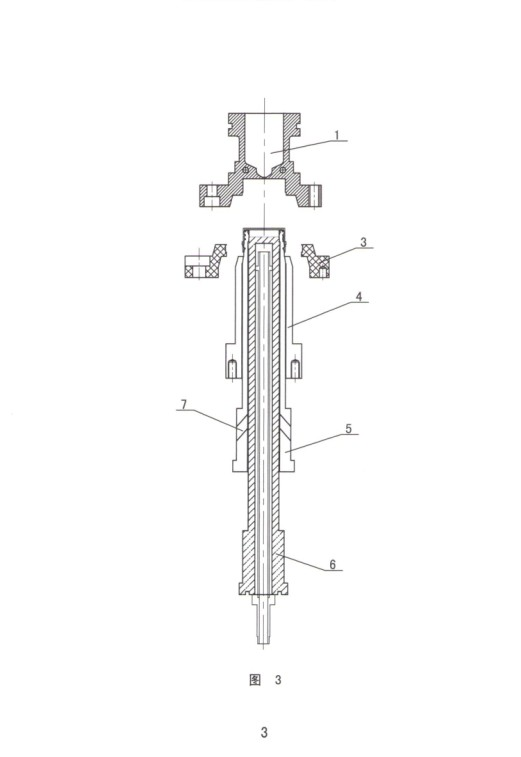

[0011] The invention relates to a double cooling device for a plastic bottle cap mould, such as Figure 1-Figure 4 As shown, it includes a cavity 1, a slider 3, a cover sleeve 4, an outer core 5 and an inner core 6, and a cooling water tank 2 is opened on the outer wall of the cavity 1, which is characterized in that the cavity 1 is near the nozzle. There are cooling water channel holes 8, the top of the inner core 6 made of beryllium bronze is in contact with the nozzle of the cavity, and the outer core 5 installed outside the inner core 6 is made with a blowing hole 7, and the blowing hole 7 faces inward The top of the core 6 is inclined so that the air reaches the mouth of the cap-off sleeve and cooperates with the cap-off sleeve 4 to push out the bottle cap. The slide block 3 is located between the cap-off sleeve 4, the outer core 5 and the cavity 1. The main feature is that there is a cooling water tank 2 on the outer wall of the cavity 1, and a cooling water channel hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com