Imitation plating processing method for surface of automobile exterior decoration

A processing method and technology of exterior decoration parts, applied in the direction of pretreatment surface, device for coating liquid on the surface, sputter plating, etc., can solve problems such as high cost, increase production cost, and affect the environment, and achieve the solution of coating stress problems, good corrosion resistance, and small power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

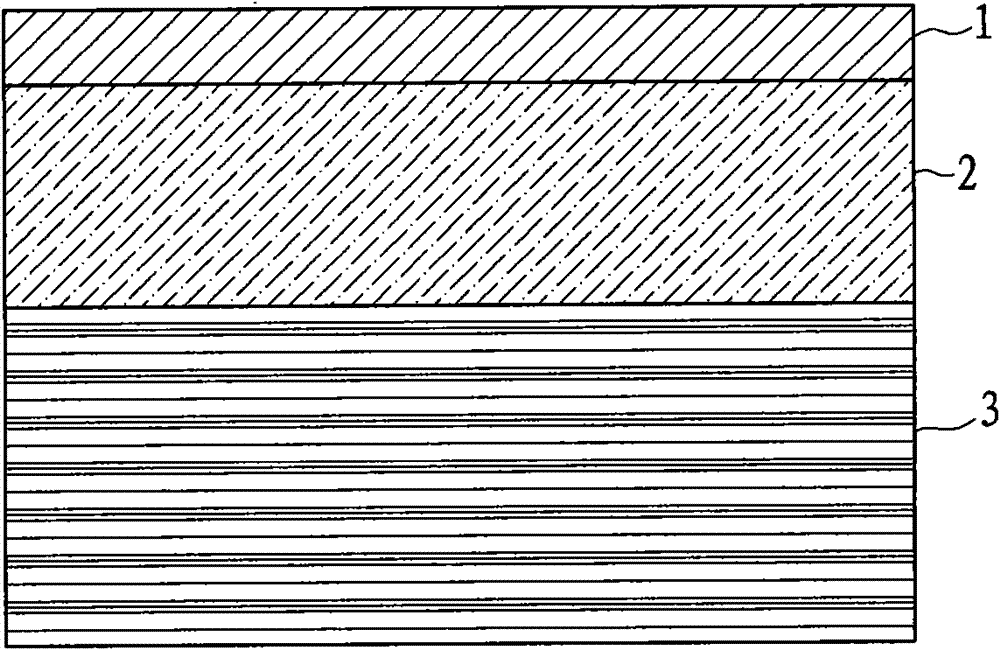

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] The surface imitation electroplating processing method of the automobile exterior trim in this embodiment comprises the following steps in turn:

[0032] ①Dry ice cleaning, using granular dry ice to impact the surface of the substrate under the drive of high-pressure air for cleaning. When the low-temperature dry ice contacts the surface of the product, due to the existence of heat exchange, the dirt on the surface of the substrate will undergo physical changes of thermal expansion and contraction, destroying and The combination of products and the use of sublimated dry ice volume expansion at the same time generate blasting force, so that surface dirt can be quickly removed. The air pressure is 0.2-0.6Mpa (the best is 0.4Mpa), and the flow rate is 1-4 cubic meters per minute (the best is 0.4Mpa). The best is 2 cubic meters per minute),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com