Integral-assembling type heat-insulating oil pipe connection structure

A technology for insulating oil pipes and connecting structures, which is applied in the direction of protecting pipes, casings, and threaded connections through heat insulation, which can solve problems such as corrosion, reduce heat loss, solve joint thread leakage, and improve heat insulation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

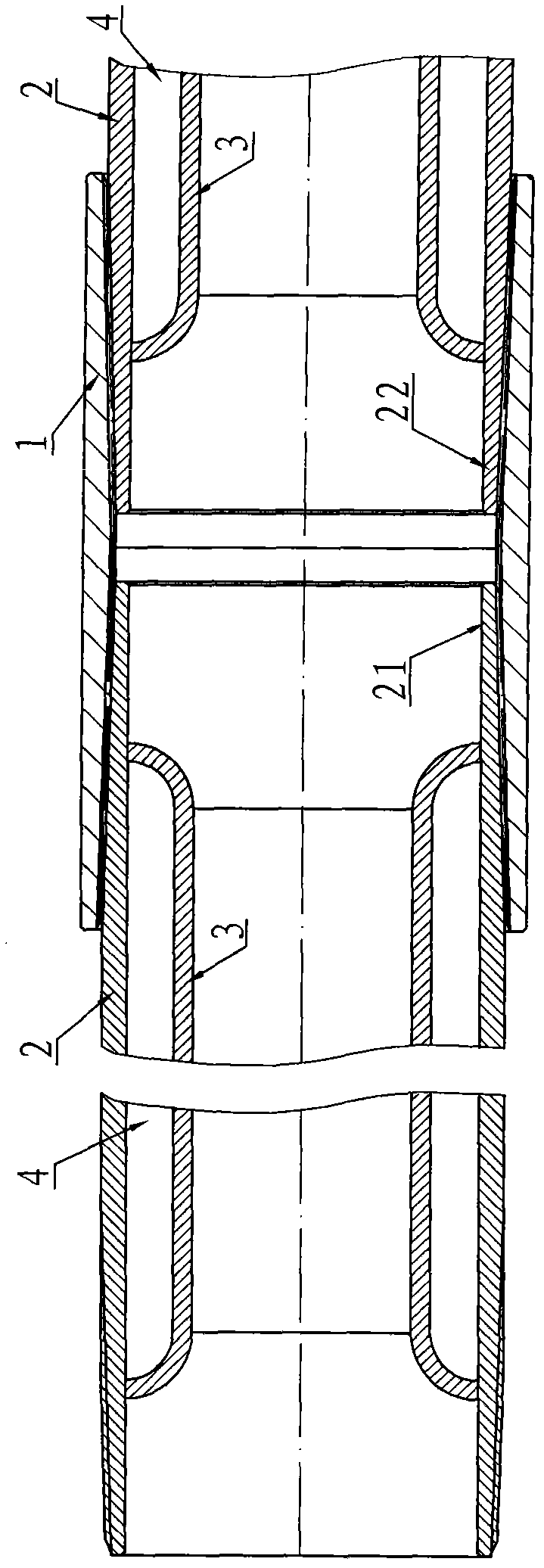

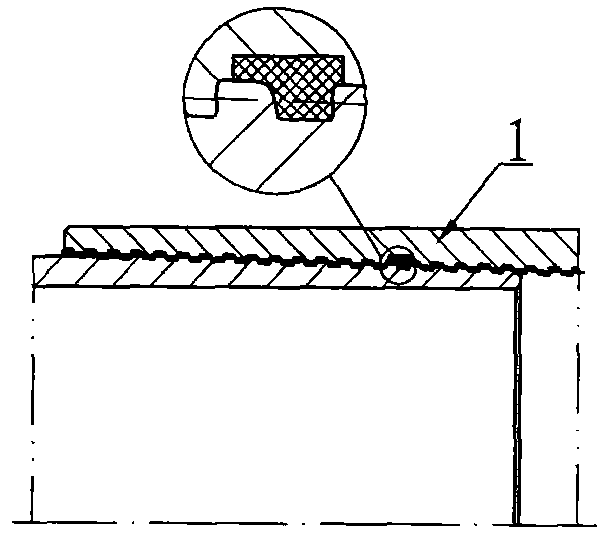

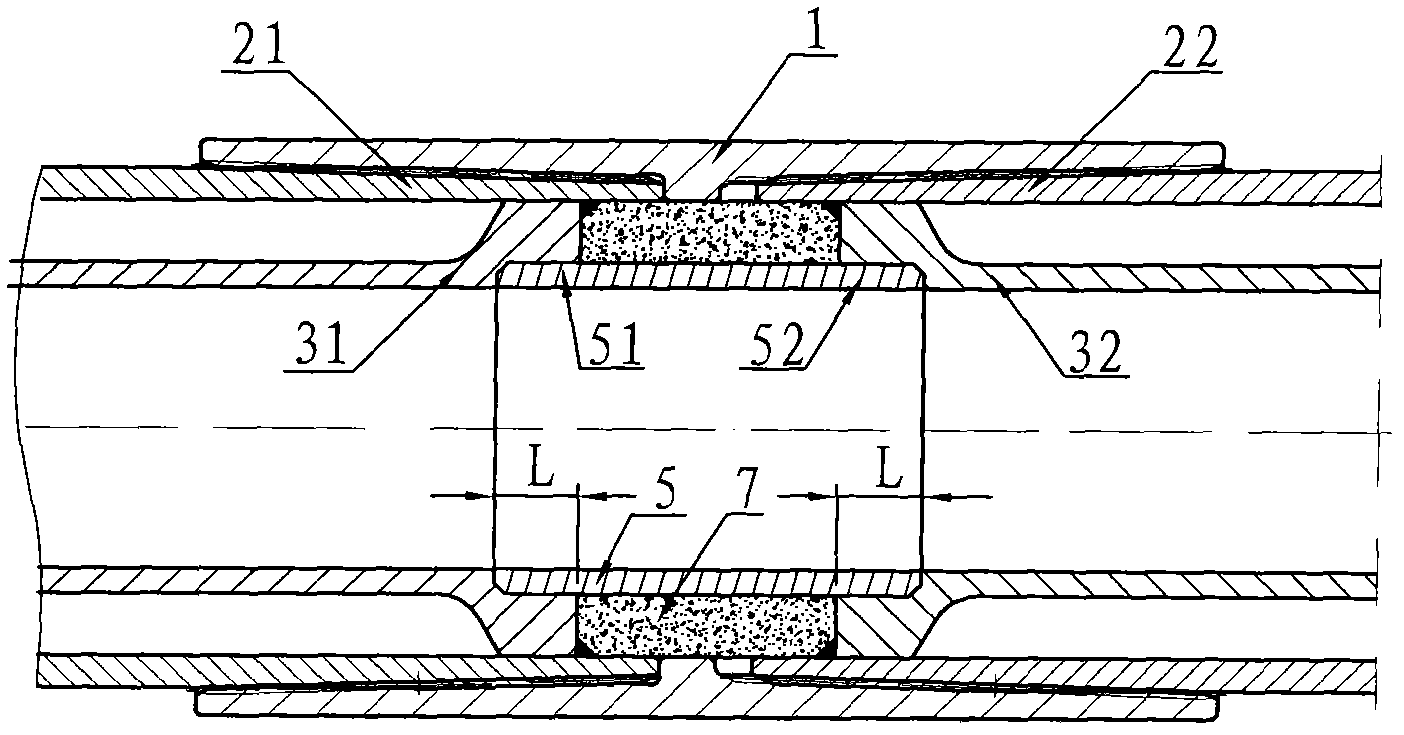

[0033]Embodiment 1: The connection structure of the overall jacketed heat-insulated oil pipe, such as image 3 As shown, it includes the coupling 1, the factory end 21 of the outer pipe threaded with the left end of the coupling 1, the user end 22 of the outer pipe threaded with the right end of the coupling 1, and the factory end 21 of the outer pipe is welded sealingly with the inner pipe factory End 31, in the outer pipe user end 22, is welded with the pipe user end 32 in the pipe body sealingly, is provided with the pipe end inner pipe 5 between the pipe factory end 31 in the pipe body and the pipe user end 32 in the pipe body, and the pipe factory end in the pipe body 31 and the pipe user end 32 in the pipe body are all provided with a butt joint, the axial length of the butt joint is L, and the inner pipe 5 factory end 51 of the pipe end is press-fitted on the butt joint of the pipe factory end 31 in the pipe body with an interference fit. In the mouth, the matching leng...

Embodiment 2

[0034] Embodiment 2: The connection structure of the overall set type heat insulation oil pipe, such as Figure 4 ~ Figure 8 As shown, it includes the coupling 1, the factory end 21 of the outer pipe threaded with the left end of the coupling 1, the user end 22 of the outer pipe threaded with the right end of the coupling 1, and the factory end 21 of the outer pipe is welded sealingly with the inner pipe factory End 31, in the outer pipe user end 22, is welded with the pipe user end 32 in the pipe body sealingly, is provided with the pipe end inner pipe 5 between the pipe factory end 31 in the pipe body and the pipe user end 32 in the pipe body, and the pipe factory end in the pipe body 31 and the pipe user end 32 in the pipe body are provided with a butt joint, the axial length of the butt joint is L, and the inner pipe factory end 51 of the pipe end is press-fitted in the butt joint of the pipe factory end 31 in the pipe body by interference fit , the matching length L betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com