Light diffusion structure of light tube and manufacturing method of light diffusion structure

A manufacturing method and lamp technology, which can be applied in the direction of light source, point light source, and elongated light source, etc., can solve the problem of strong light discomfort and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

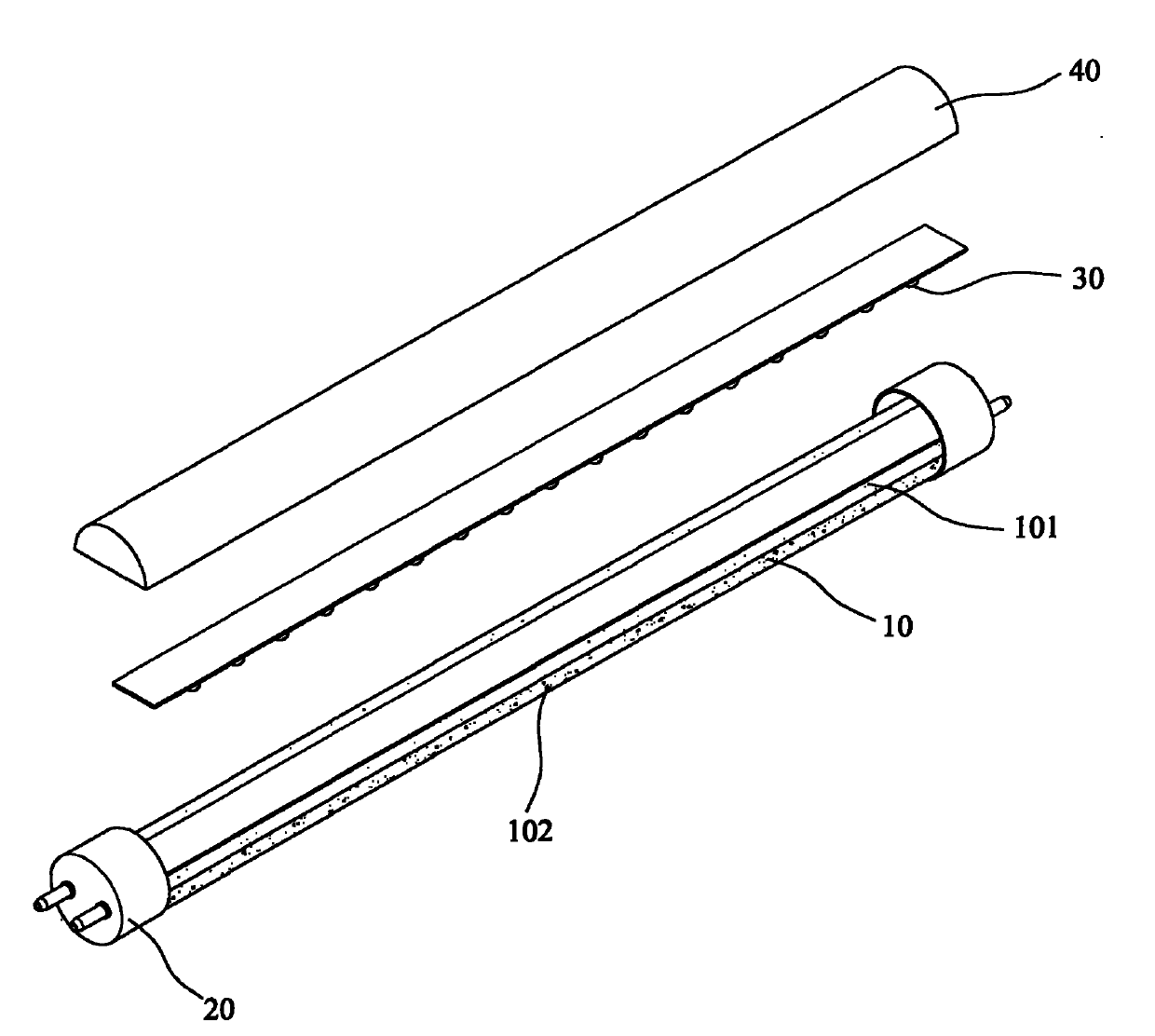

[0021] See first figure 1 As shown, the light expansion structure of the lamp tube of the present invention includes: a plurality of joints 20 provided with at least one light source 30, and a glass tube 10 is arranged on the joint 20 to cover the light source 30, and the glass tube 10 has a rough surface 102, and the glass tube 10 is attached with an adhesion layer 101.

[0022] The above-mentioned light source 30 is an LED lamp, and the above-mentioned adhesion layer 101 and the rough surface 102 are respectively arranged on the inner surface and the outer surface of the glass tube 10. The above-mentioned adhesion layer 101 is a gold-plated or silver-plated metal layer or a reflective material, and the adhesion layer 101 Covering at least one-fifth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com