Tubular heat exchanger for motor vehicle air conditioners

A technology for automotive air conditioners and heat exchangers, applied in the direction of indirect heat exchangers, heat exchanger types, tubular components, etc., can solve problems such as pipe diameter and pipe length limitations, high pressure loss, and unfavorable performance of air conditioning systems, etc., to achieve The effect of high heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

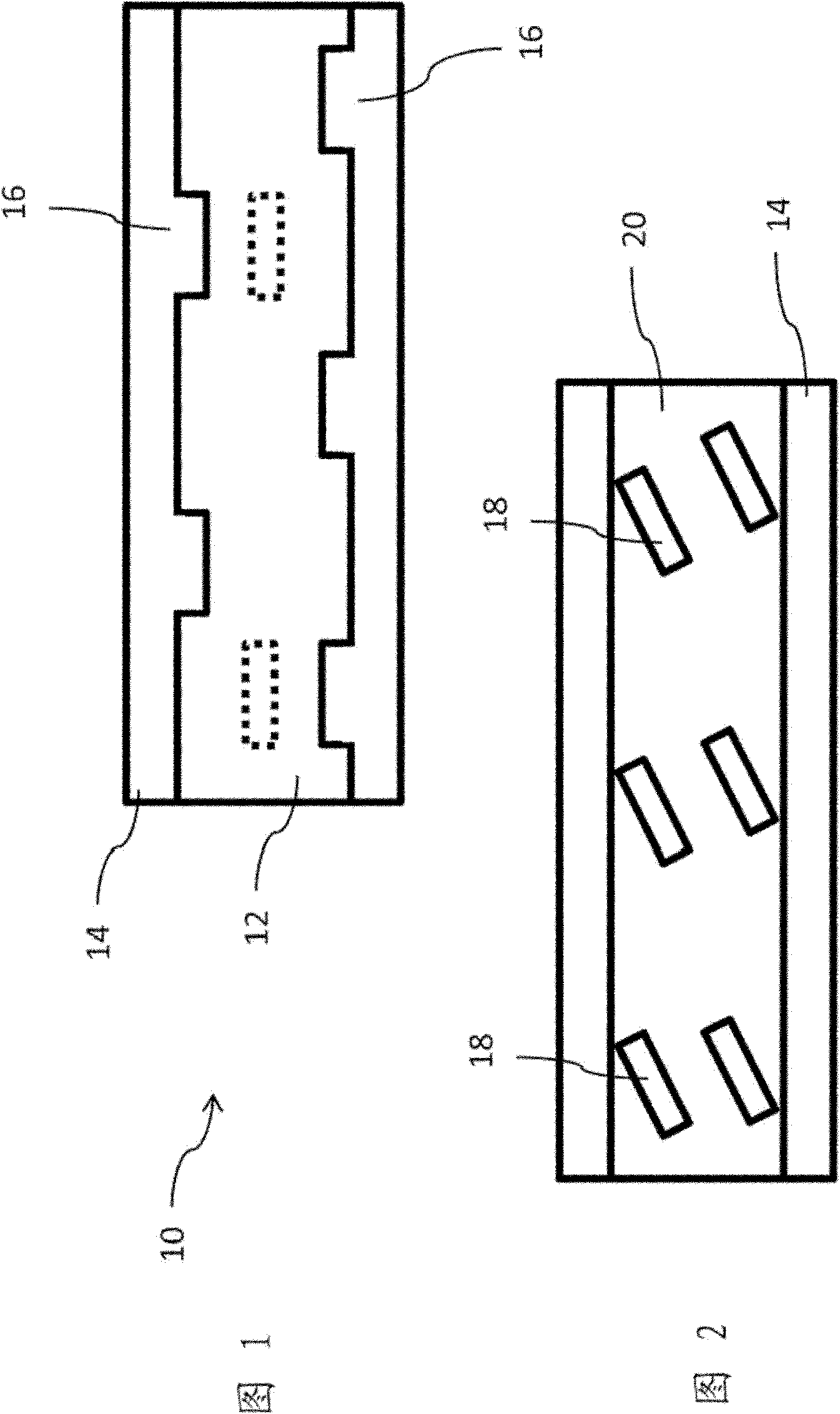

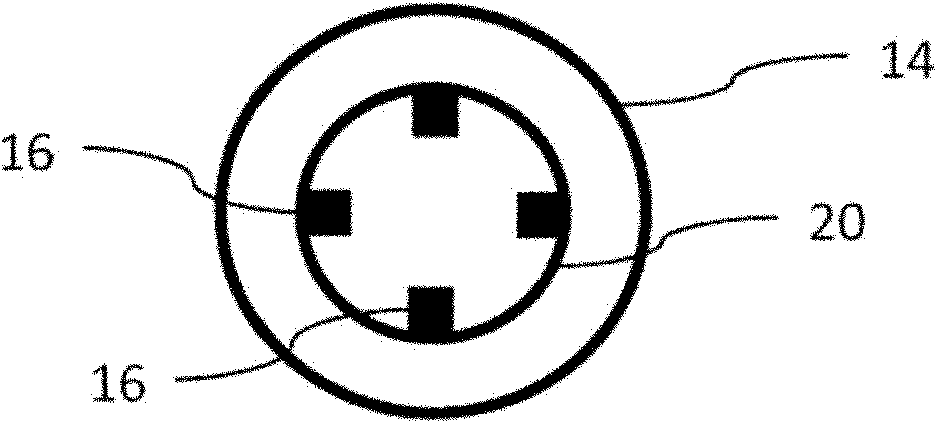

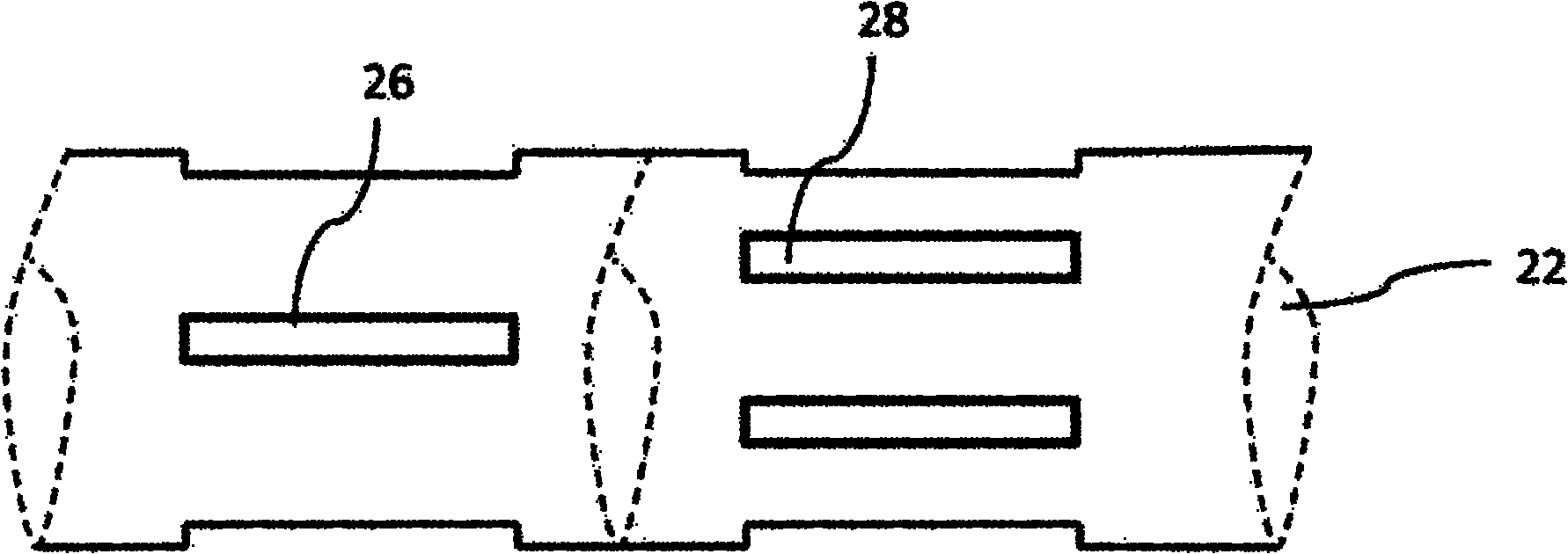

[0040] exist Figure 1 to Figure 3 In , a coaxial tube heat exchanger 10 with an inner tube 12 and an outer tube 14 is shown. The inner tube 12 is provided with a single inwardly protruding embossment 16, while the outer tube 14 has a substantially continuous cylindrical shape. To this end, embossments 16 designed as grooves in the outer surface of the inner tube 12 protrude correspondingly from the inner surface of the inner tube 12 .

[0041] The inner pipe is mainly used to connect the evaporator and the compressor of the automobile air-conditioning device in a fluid sense. One end of it is connected to the outlet of the evaporator, and the other end is connected to the suction end of the compressor. The outer tube 14 or the outer channel formed by the outer tube 14 and the inner tube 12 is preferably used to flow refrigerant under high pressure in the opposite direction to the vapor refrigerant flowing through the inner tube 12 .

[0042] In this case, the high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com