Ultrafiltration membrane bubble point determinator and ultrafiltration membrane average pore size determination method

A technology of average pore size and measurement method, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of solution concentration and working pressure difference, difficulty in selection, and measurement of difficult standard particle method, so as to improve the measurement efficiency and improve the measurement process. Fast, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

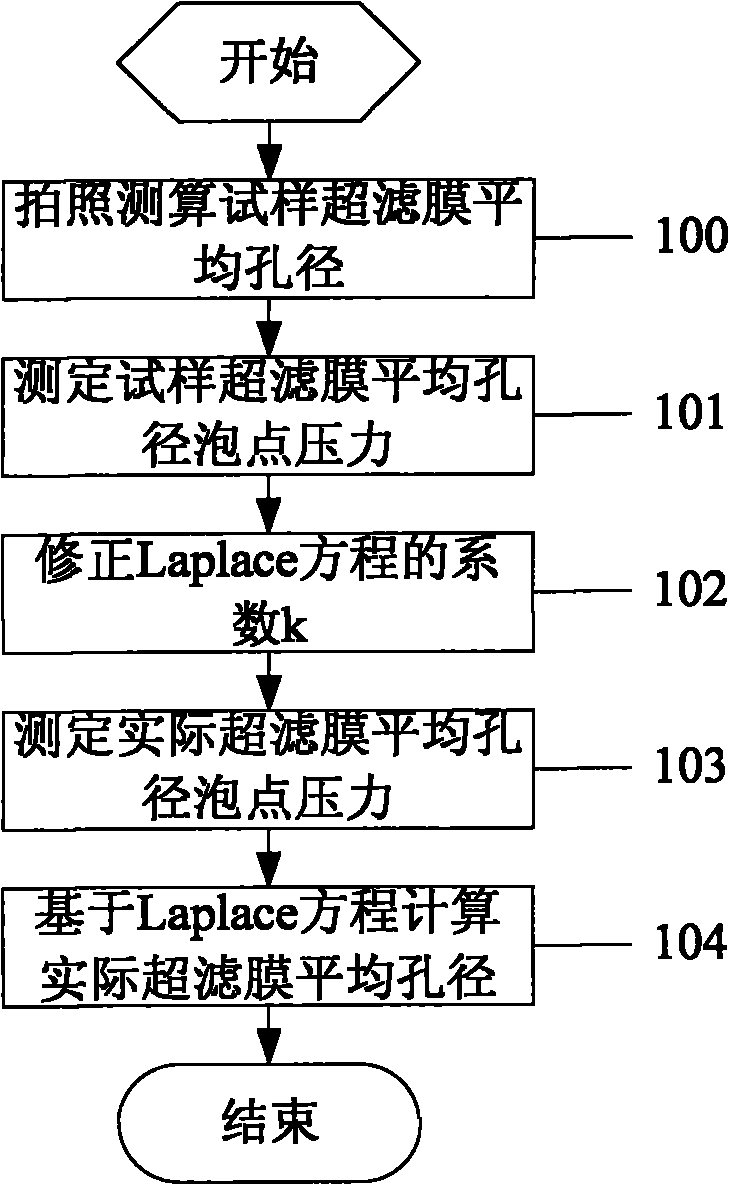

[0021] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

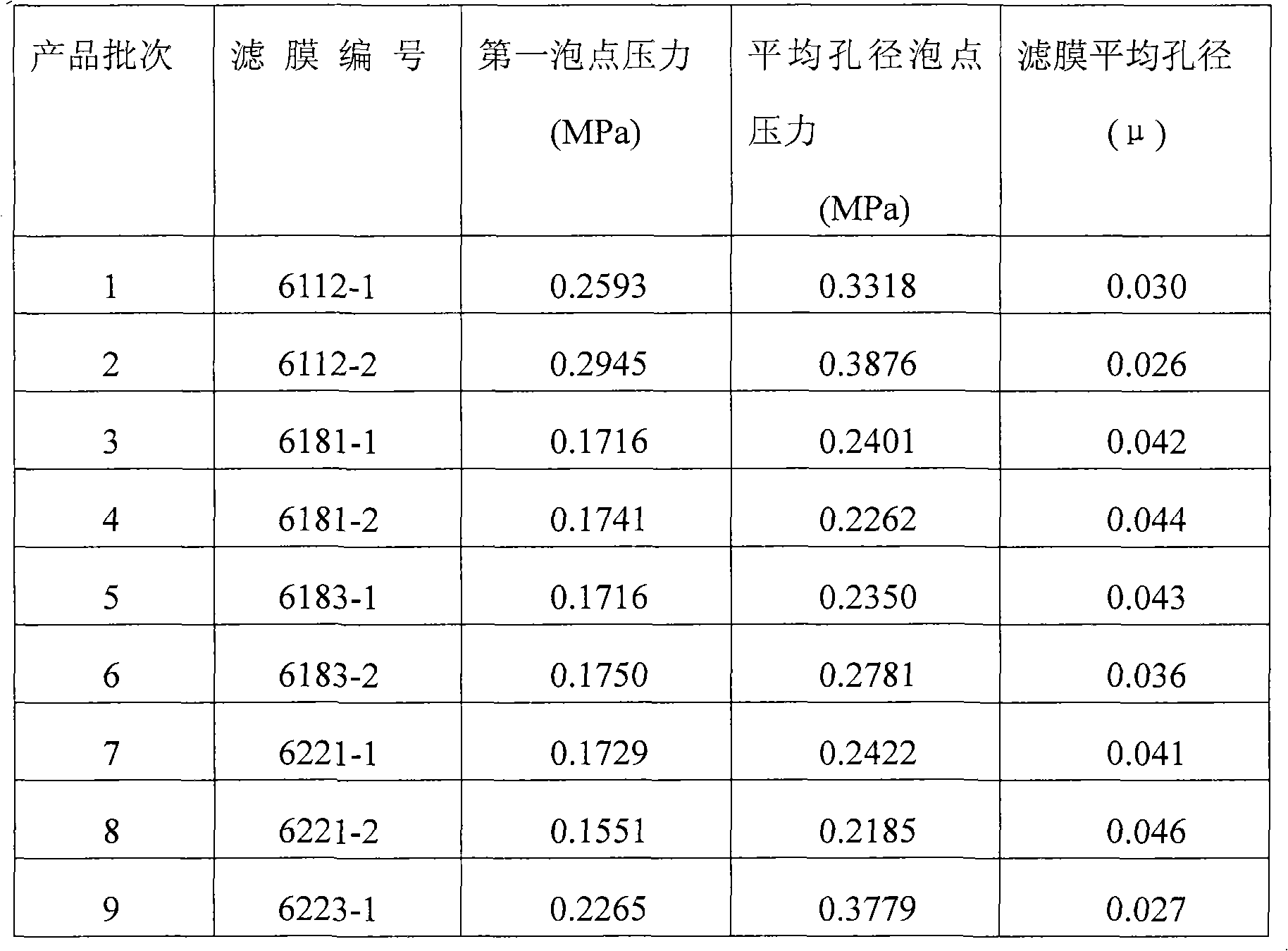

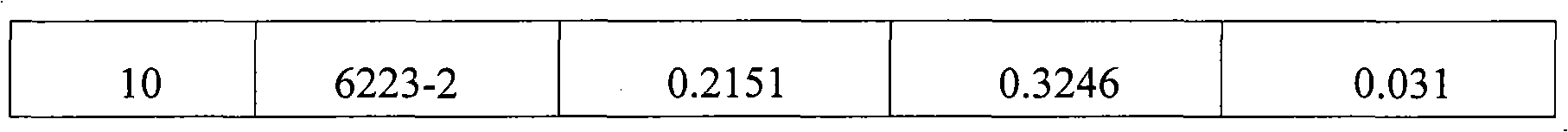

[0022] The ultrafiltration membrane bubble point tester of the present invention includes an average pore size bubble point pressure measurement module similarly to the existing bubble point tester. The working principle of the average pore size bubble point pressure measurement module is as described in the background technology. With the continuous increase of the air pressure in the air chamber, the module will continuously test all the components in the air-ventilating state (bubbling state) on the ultrafiltration membrane to be tested. ) to detect the total ventilation air flow of the micropores, and continuously compare the air flow obtained by detection with a preset judgment standard, once the air flow reaches the preset judgment standard, it is judged that the air flow at this ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com