Fiber grating acceleration transducer based on metal bellows structure

A technology of acceleration sensor and metal bellows, which is applied in the direction of acceleration measurement by using inertial force, can solve the problems of poor anti-lateral interference ability, inaccurate measurement results, inconsistent vibration direction, etc., and achieves easy series assembly and improved sensitivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

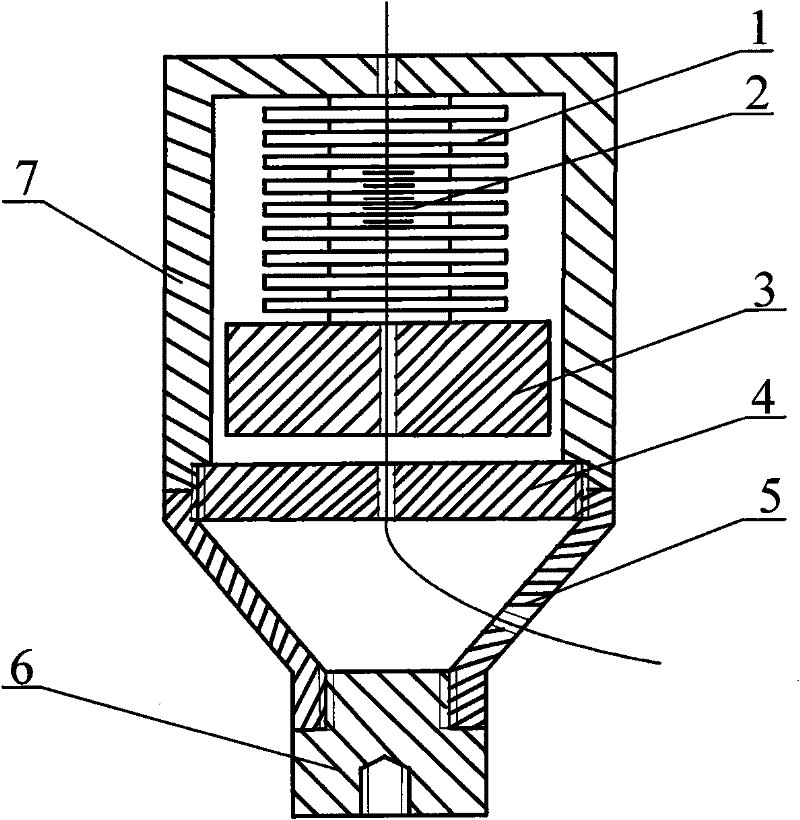

[0020] exist figure 1 Among them, a fiber grating acceleration sensor based on a metal bellows structure in this embodiment is connected by a metal bellows 1, a vibration sensing fiber grating 2, a mass 3, an end cover 4, a sealing cover 5, a sensor connector 6, and a housing 7 constitute.

[0021] The shell 7 of this embodiment is a cylindrical structure, and the upper end of the metal bellows 1 is bonded to the lower surface of the inner top of the shell 7 with 502 glue. The metal bellows 1 is a beryllium bronze metal bellows, and the inner diameter of the metal bellows 1 is 18mm. , The outer diameter is 24mm, the wave pitch is 5mm, the wave thickness is 0.12mm, and the wave number is 9. The lower end of the metal bellows 1 is pasted with 502 glue to fix the quality block 3. The 502 glue is a commodity sold in the market and produced by Taizhou Jiaojiang Tuopu Adhesive Factory. The center of the quality block 3 is processed with a through hole. The mass in this embodiment ...

Embodiment 2

[0024] In this embodiment, the upper end of the metal bellows 1 is bonded to the lower surface of the inner top of the housing 7 with 502 glue, and the lower end of the metal bellows 1 is fixed to the mass block 3 with 502 glue. The inner diameter of the metal bellows 1 is 18mm , the outer diameter is 24mm, the wave pitch is 5mm, the wave thickness is 0.14mm, the wave number is 10, the quality of the mass block 3 is 15g, and the distance between the upper surface of the end cover 4 and the lower surface of the mass block 3 is 10mm. A vibration sensing fiber grating 2 is installed in the metal bellows 1, and the upper part of the optical fiber of the vibration sensing fiber grating 2 is led out from the central through hole of the housing 7 and fixed on the central hole of the outer surface of the housing 7 with 502 glue. The lower part of the optical fiber of the fiber grating 2 passes through the central through hole of the mass block 3 and is pasted and fixed on the central t...

Embodiment 3

[0026] In this embodiment, the upper end of the metal bellows 1 is bonded to the lower surface of the inner top of the housing 7 with 502 glue, and the lower end of the metal bellows 1 is fixed to the mass block 3 with 502 glue. The inner diameter of the metal bellows 1 is 10 mm , the outer diameter is 15 mm, the wave pitch is 3 mm, the wave thickness is 0.1 mm, the wave number is 5, the mass of the mass block 3 is 7.5 g, and the distance between the upper surface of the end cover 4 and the lower surface of the mass block 3 is 1 mm. A vibration sensing fiber grating 2 is installed in the metal bellows 1, and the upper part of the optical fiber of the vibration sensing fiber grating 2 is led out from the central through hole of the housing 7 and fixed on the central hole of the outer surface of the housing 7 with 502 glue. The lower part of the optical fiber of the fiber grating 2 passes through the central through hole of the mass block 3 and is pasted and fixed on the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com