Neutron flux measuring thimble tube replacing process of nuclear reactor core measuring system and specific device thereof

A technology of flux measurement and special equipment, which is applied in the field of neutron flux measurement finger-casing tube replacement technology and its special equipment in the core nuclear test system, which can solve problems such as high risk, jamming powerlessness, and finger-casing breakage, etc. Achieve the effects of reducing radiation dose, reducing container usage, and short replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

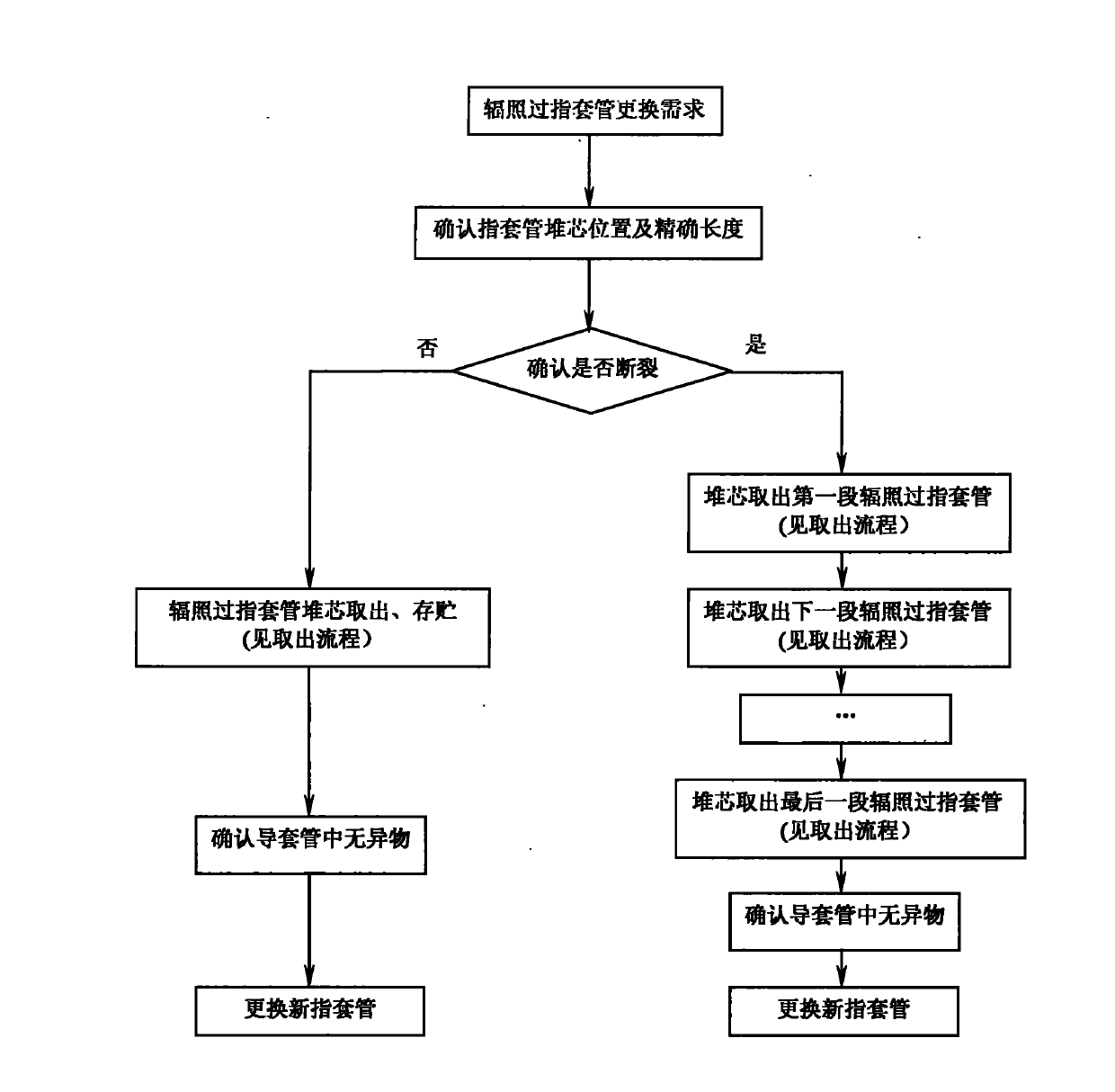

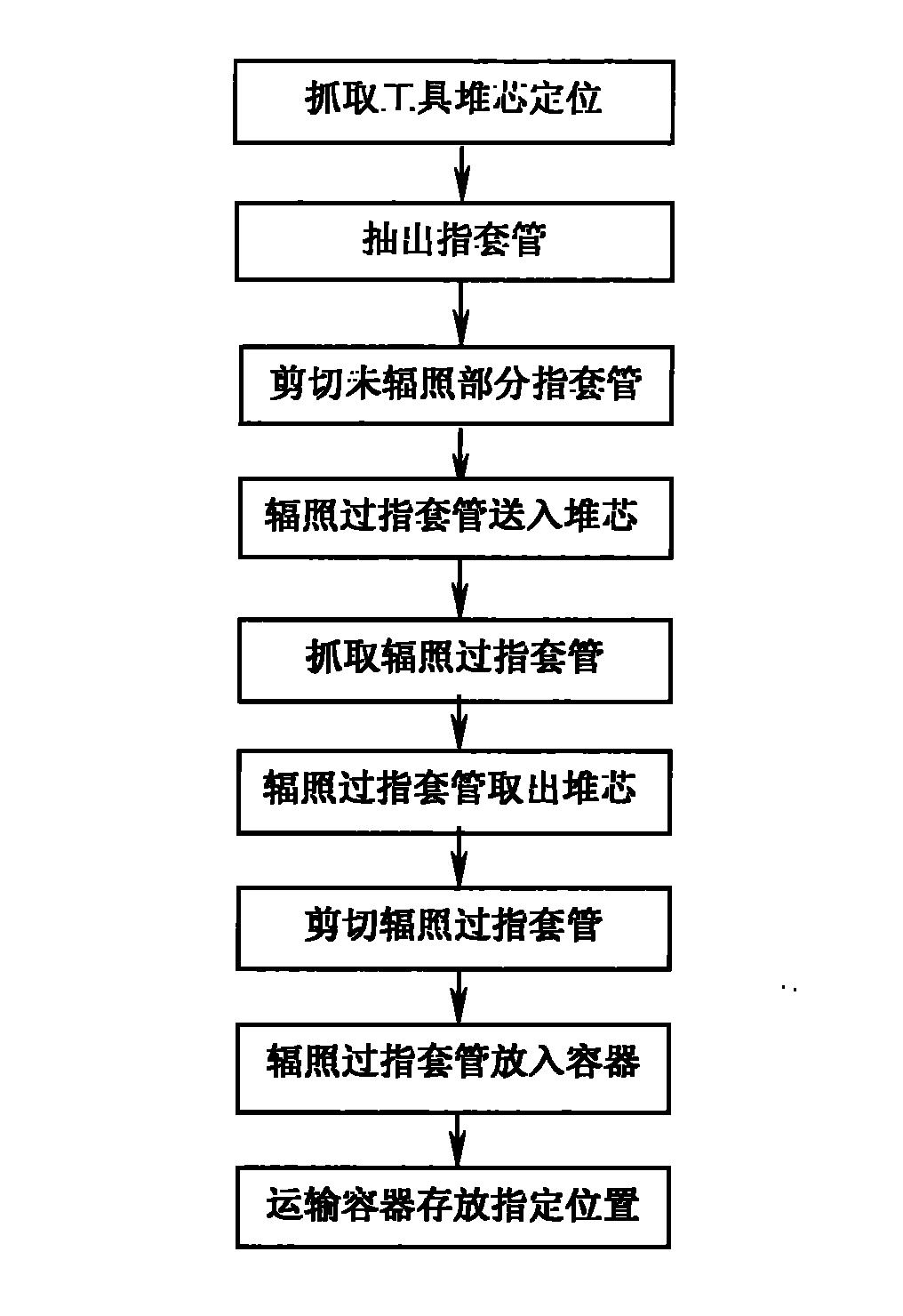

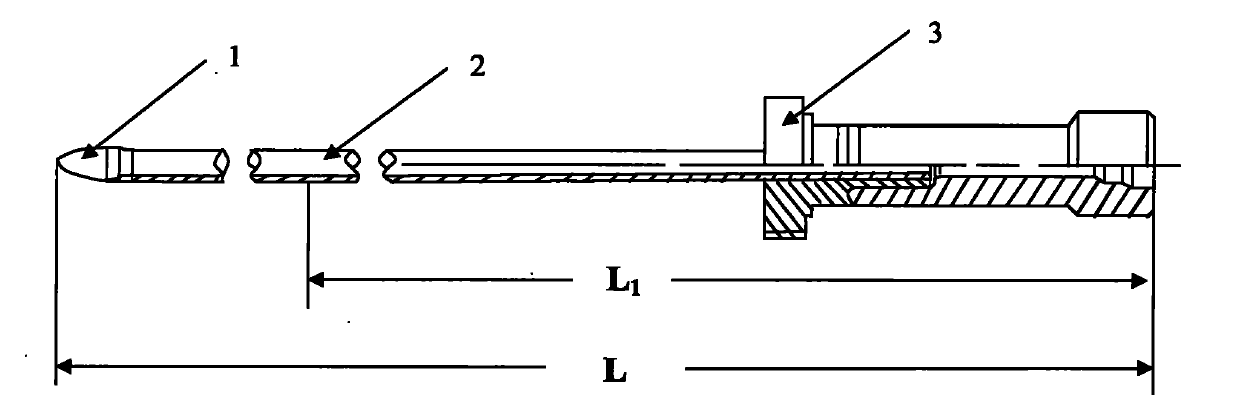

[0053] The structure of the bushing assembly is as follows image 3 As shown, it includes a bullet-shaped head 1 , a middle section of the finger sleeve 2 and a sealing flange part 3 of the finger sleeve. Refers to the position of the bushing assembly in the core such as Figure 5 As shown, the finger sleeve 7 passes through the guide sleeve 6 of the finger sleeve to reach the core lower plate 5 .

[0054] The overall structure of the special equipment for finger sleeve replacement provided by the present invention is as follows: Figure 6 As shown, it includes an underwater grasping tool 10 for grabbing the irradiated part of the finger cannula and a simulated finger cannula 9 with size marks. The structure of the simulated finger cannula 9 is as follows Figure 4 As shown, the underwater grabbing tool 10 is suspended and connected to the hook ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com