Method of producing clostridium botulinum toxin using media containing plant-derived components and flexible closed container

一种肉毒梭菌、密闭容器的技术,应用在生物化学设备和方法、酵素、细菌等方向,能够解决存在高危因素、高投资成本、大劳动力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

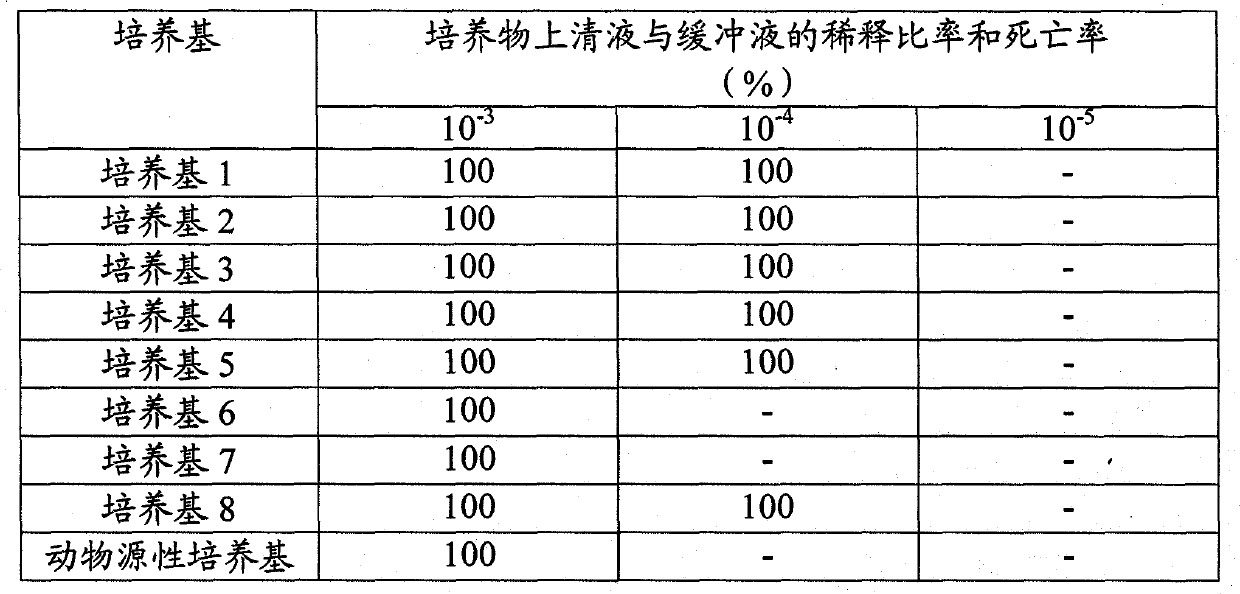

[0049] Example 1: Validation of medium composition to produce high levels of Clostridium botulinum toxin type A expressed outside the cell

[0050] The fact that a large amount of botulinum toxin type A is expressed extracellularly in media free of animal-derived components was verified using various plant media.

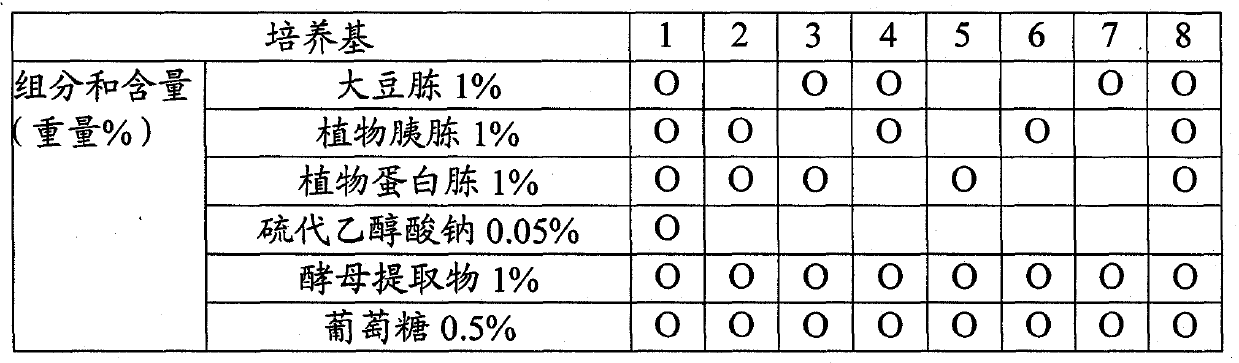

[0051] The media used are shown in Table 1 below.

[0052]

[0053] [Table 1]

[0054] [sheet]

[0055]

[0056] In Table 1, products manufactured by Beckton Dickinson and Fluka were used as soytone and phytotryptone, respectively. In addition, products manufactured by Becton-Dickinson were used as plant peptone and yeast extract, and products manufactured by Merck were used as glucose. The medium components of Table 1 were dissolved in water for injection (WFI), and the pH of the resulting solution was adjusted to 7.2 using NaOH.

[0057] In addition, 1% by weight of N-Z amine A (Sigma (Sigma): animal origin), 2% by weight of Bacto peptone (Proteose Pep...

example 2

[0075] In addition to not using Cultibag while culturing TM This example was performed in the same manner as Example 1 except that shaking was performed.

[0076] As a result, there was no substantial difference between the amount of toxin produced and that of Example 1.

example 3

[0077] Example 3: Isolation of meat type A from culture supernatant using media containing plant-derived components Clostridium toxin

[0078] Clostridium botulinum was cultured using medium 5 of Example 1 or 2, and botulinum toxin type A was isolated from the supernatant from which the cells had been removed. The culture conditions and time and the cell removal process were the same as in Example 1.

[0079] 0.1 N sulfuric acid was added to the bag containing 20 L of the culture supernatant to adjust the pH of the resulting solution to be in the range of 3.0 to 4.5, and thus, precipitate the toxin protein. Perform this procedure in a disposable sample bag that does not come into contact with the outside.

[0080]Next, when the precipitation was completed, the resulting solution was filtered through a pre-sterilized disposable filtration system (disposable sheet 2000.2 μm filter, manufactured by Sartorius Corporation) that was not in contact with the outside to remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com