Special vibrating screen mechanism for dry-process sand milling dust removal complete equipment

A complete set of equipment, vibrating screen technology, applied in filter screens, chemical instruments and methods, separation of solids from solids by air flow, etc. Power consumption, improve service life, avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

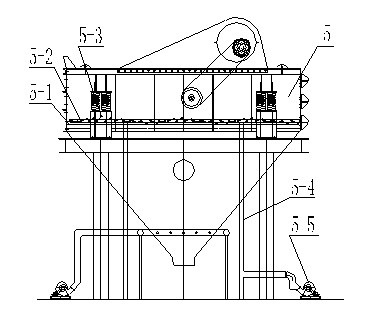

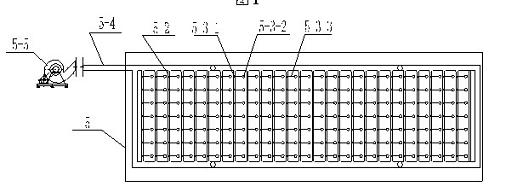

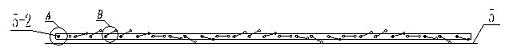

[0018] Embodiment 1: with reference to attached Figure 1-5 . The special vibrating screen mechanism for dry sand grinding and dust removal equipment includes a vibrating screening mechanism 5. The vibrating screen in the vibrating screening mechanism 5 is composed of three layers of screens, and the distance between the three layers of screens is distributed up and down. The apertures of the nets are different and become smaller from top to bottom, and a blowing device is arranged above the surface of the third layer of screen. Described blowing device is made of many rows of air ducts 5-2, has a plurality of blowing nozzles 5-2-1 on the multi rows of air ducts 5-2 facing screen 5-1, and multi rows of air ducts 5-2 Connect with the air outlet of the fan 5-5 through the main air duct 5-4, see attached image 3 and 4 . Described screen cloth 5-2 face is provided with a plurality of bouncing balls 5-3, and bouncing ball 5-3 sets is fixed on the air duct 5-2 and can jump up a...

Embodiment 2

[0021] Embodiment 2: on the basis of embodiment 1, with reference to appended Figure 6 . A complete set of equipment for dry sand grinding and dust removal, which includes feed inlet 1, feeder 2, cone sand making machine 3, dust collector 4, vibration screening mechanism 5, feed inlet 1 is located at the input end of feeder 2, feeder 2 The output end is located at the feed port 3 of the cone sand making machine, and the discharge port 3 of the cone sand making machine is directly facing the feed port 5 of the vibrating screening mechanism. The distance between them is distributed up and down, and the apertures of the three layers of screens are different, and become smaller from top to bottom. A blowing device is arranged above the surface of the third layer of screens, and a blower is installed above the feed port of the cone sand making machine 3. There is a water mist nozzle or a water mist pressure dust cover, a water mist pressure dust cover is provided above the feed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com