Multi-spindle U drill gang spindle box and U drill gang high-speed numerical control drilling machine

A spindle box and spindle technology, applied in drilling/drilling equipment, parts of boring machine/drilling machine, boring/drilling, etc., can solve problems such as high efficiency and high quality, and improve hole processing smoothness and performance Good, extended tool life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

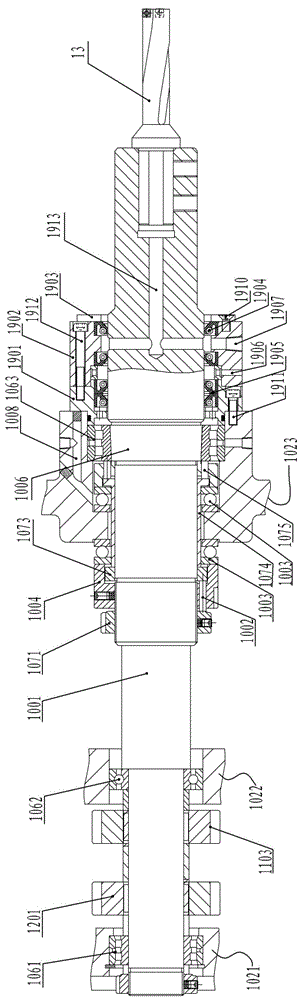

[0027] In this embodiment, the inner ring of the roller bearing located in the shaft hole of the support wall 1023 is a tapered hole (the diameter of the drill port is larger), and the tapered flange matched with the tapered hole is pressed by a specially designed The mechanism tightly presses the tapered flange and the tapered inner ring of the bearing together. The pressing mechanism includes a lock nut between the threaded section and the inner ring of the roller bearing, three 7131 short shafts, a backing ring, a top sleeve, and three 7127 short shafts which are sequentially connected. The lock nut is installed on the threaded section, the three 7131 short shafts are installed in the relief holes of the compression nut 1004, the top sleeve is set between the thrust bearing and the main shaft, and the backing ring is located between the three 7131 short shafts and the top Between the sleeves, three 7127 short shafts are installed in the relief holes of the compression sleev...

Embodiment 2

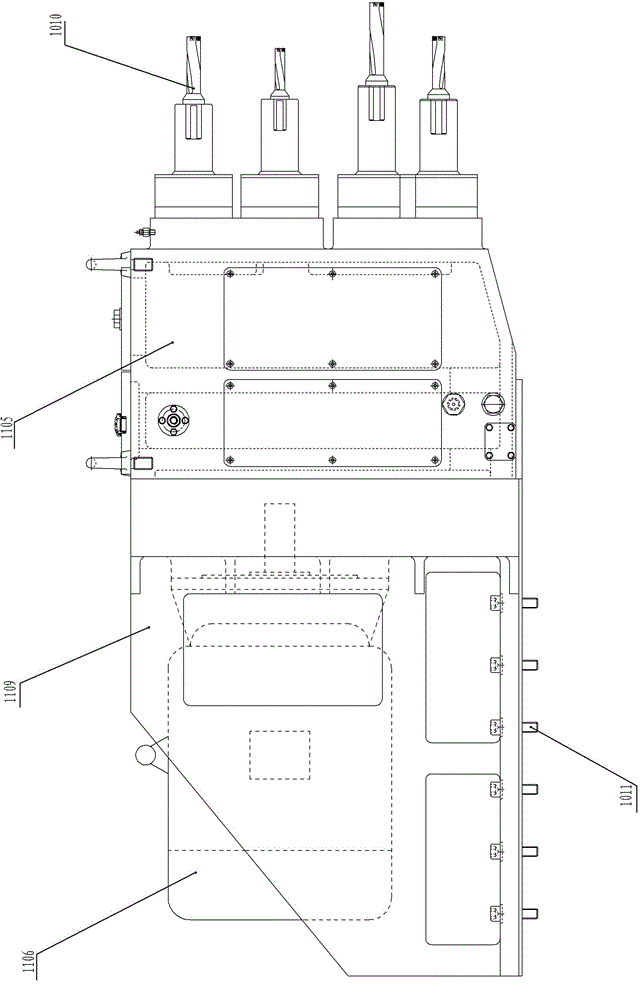

[0078] The longitudinal CNC sliding table includes a base, the lower end of which is fixed on the machine tool base, and the upper end of the base slides with the moving part of the CNC sliding table through guide wheels and guide rails. A controllable workpiece fixture is installed on the vertical CNC slide table for timely adjustment and positioning of the workpiece. One end of the vertical numerical control sliding table is also provided with an adjusting slant iron for positioning or fixing the numerical control sliding table.

[0079] The outer side of the drilling machine also includes a protective casing, and an operation panel is arranged on the casing.

[0080] A chip catcher is installed below the working area of the drill bit and the workpiece, the bottom of the chip catcher has a pulley and a motor is installed at one end thereof, and the pulley is matched and installed on the bottom slideway.

[0081] The water-cooling mechanism is equipped with a cooling pump ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap