Heavy-duty precision rotary table

A technology of rotary workbench and workbench, which is applied in the direction of manufacturing tools, large fixed members, metal processing equipment, etc., and can solve the problems of easy wear of the table surface, large frictional resistance, and affecting the machining accuracy of machine tools

Inactive Publication Date: 2011-06-15

JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the rotation of most rotary tables is driven by the meshing of a single worm gear. Due to the meshing gap of this device, it is difficult to guarantee the rotary accuracy of the table, which affects the machining accuracy of the machine tool. The traditional rotary table is due to the gap between the upper body and the lower body. The surface is in direct contact with the surface, the friction resistance is large, the table is easy to wear, and there is a great limit on the carrying capacity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

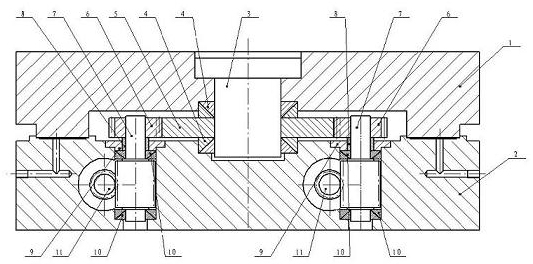

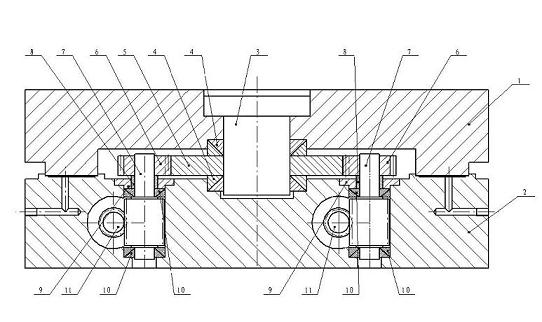

The invention relates to the machinery manufacturing industry, in particular to a heavy-duty precision rotary table, which comprises an upper body of the table, a lower body of the table, a spindle, a bearing a, a big gear wheel, a pinion, a worm wheel shaft, a flange plate, a spacer bush, a bearing b and a worm shaft, wherein the upper body of the table is connected with the lower body of the table through the spindle; the spindle is supported by the bearing a; the big gear wheel is arranged on the spindle; the pinion is arranged on the worm wheel shaft and meshed with the big gear wheel at different positions; the worm wheel shaft is supported in the lower body of the table through the bearing b and is meshed with the worm shaft; the worm wheel shaft is arranged in the lower body of the table through the flange plate; and the spacer bush is arranged between the pinion and the worm wheel. The heavy-duty precision rotary table has the advantages that: a static pressure support is formed between the upper body and the lower body of the table, and is high in bearing capacity and high in supporting rigidity; double gear meshing is adopted, the back lash between gear pairs is eliminated, and the upper body of the table has high rotary precision.

Description

A heavy-duty precision rotary table Technical field: The invention relates to the machinery manufacturing industry, in particular to a heavy-duty precision rotary table. Background technique: At present, most of the rotary table rotation is driven by single worm gear meshing. Due to the meshing gap, the rotation accuracy of the table is difficult to guarantee, which affects the machining accuracy of the machine tool. The traditional rotary table is due to the gap between the upper body and the lower body. The surface is in direct contact with the surface, the friction resistance is large, the table is easy to wear, and there is a great limit on the bearing capacity. Summary of the invention: The purpose of the present invention is to provide a heavy-duty precision rotary table, which can reduce the wear between the rotary surfaces of the rotary table, improve the supporting rigidity of the rotary table, and can simply and effectively ensure the rotation accuracy. The technic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q1/26

Inventor 戴启峰杨树根杨莲

Owner JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com