Heating wire heating device and construction method for winter concrete

A heating device and construction method technology, which is applied in the direction of manufacturing tools, ceramic molding machines, building structures, etc., can solve the problems such as the abnormal increase in the strength of concrete components, and achieve the effects of easier guarantee of safety and quality, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

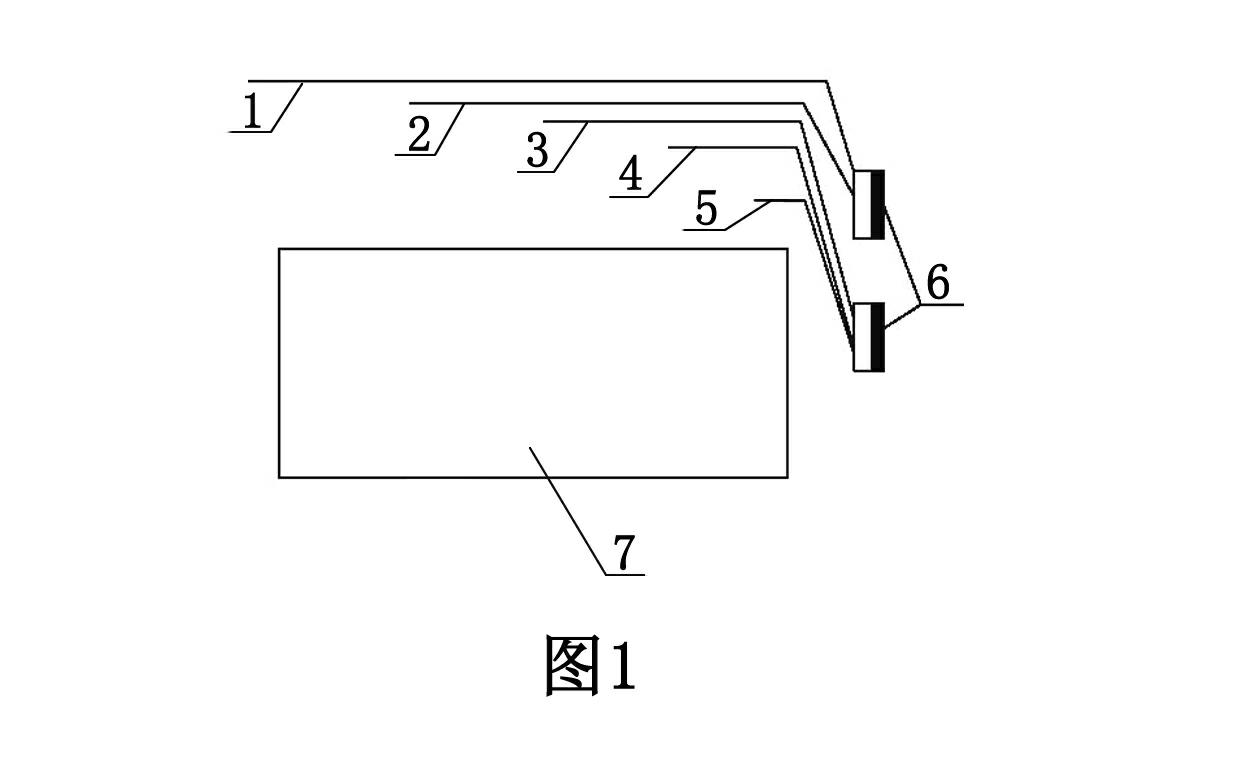

[0064] Examples see Figure 1-5 As shown, this winter concrete heating wire heating device includes a plastic cloth isolation layer 15, a heating wire heating circuit and an insulation layer. The plastic cloth isolation layer 15 is laid on the upper surface of the concrete member 7 .

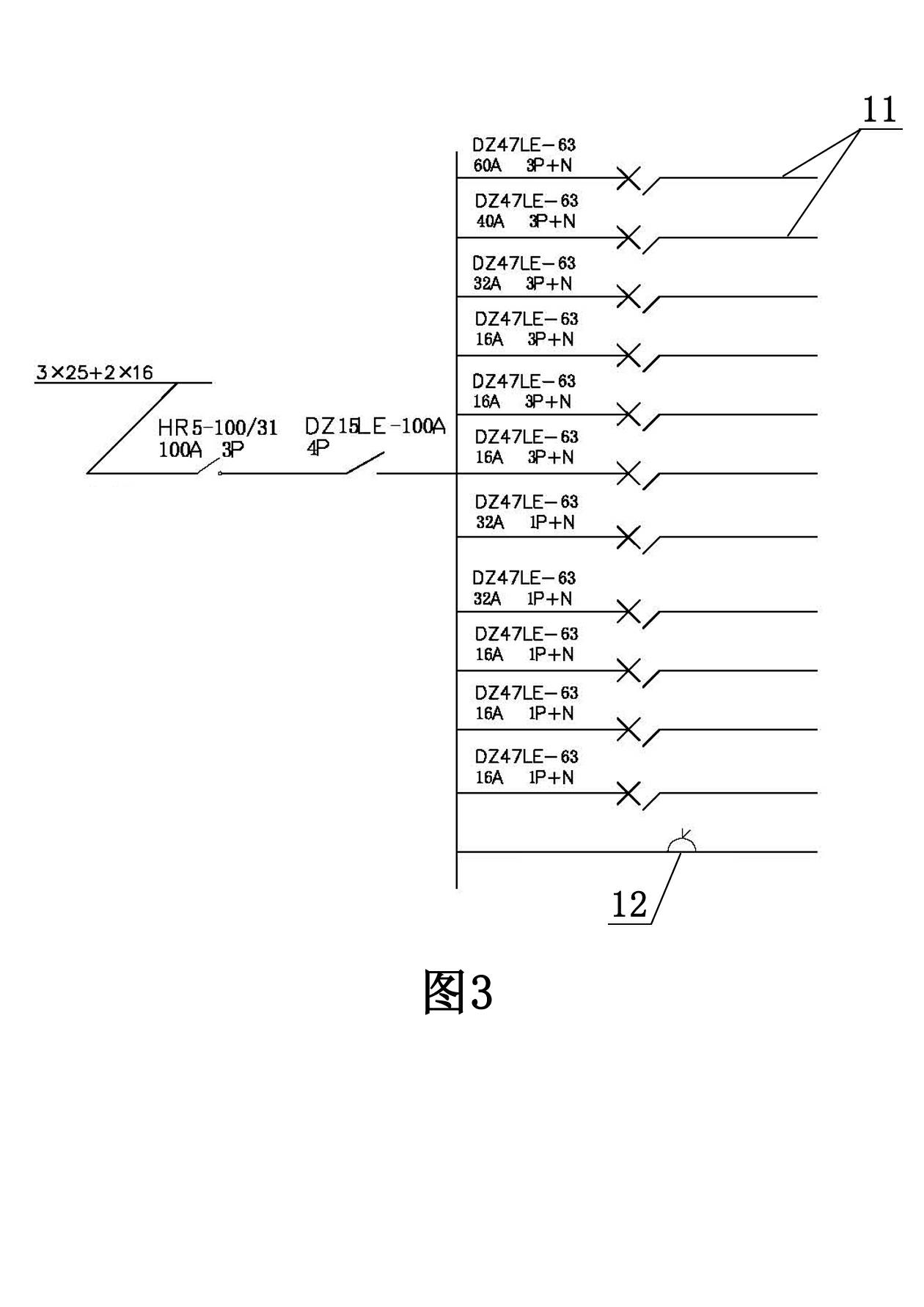

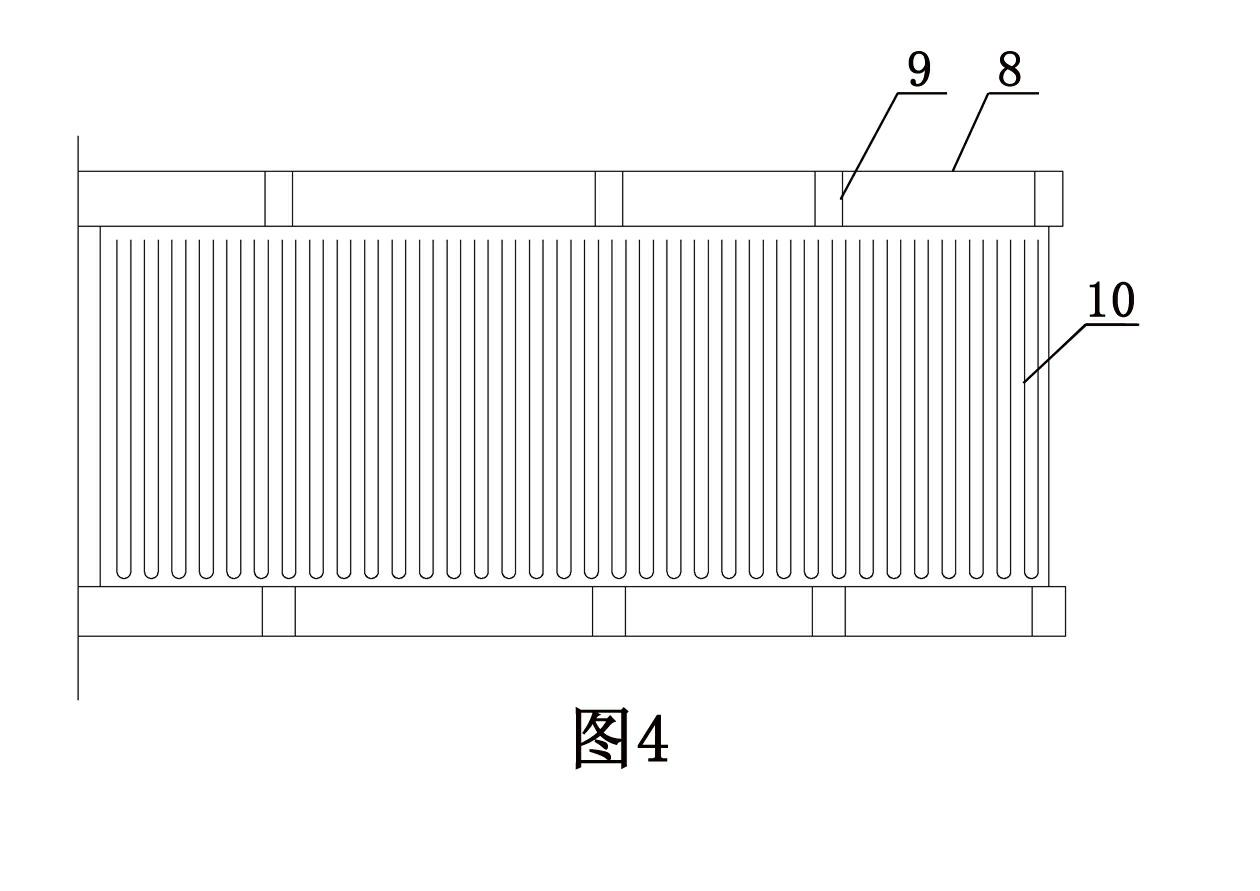

[0065] The electric heating wire heating circuit is connected by a power supply box 6 with multiple use circuits, the main line 8 of each use circuit is at least 10cm apart, and a group of electric heating wires 10 is connected by a lead wire 9, and no more than 15 groups of electric heating wires are connected to each use circuit. Heating wire. The heating wires are arranged on the plastic cloth isolation layer 15 in groups. No more than 15 sets of heating wires are connected to each of the use circuits.

[0066] The main line adopts multi-strand plastic copper wire, and the full name of plastic copper wire is copper core polyvinyl chloride insulated wire. The lead-out wire adopts multi-str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com