Wireless motor-driven carrier vehicle

A transport vehicle and radio technology, applied in the field of wireless electric transport vehicles, can solve the problems of heavy raw materials and semi-finished products, laborious transportation, inconvenient and other problems, and achieve the effect of reasonable structure, easy maintenance and strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

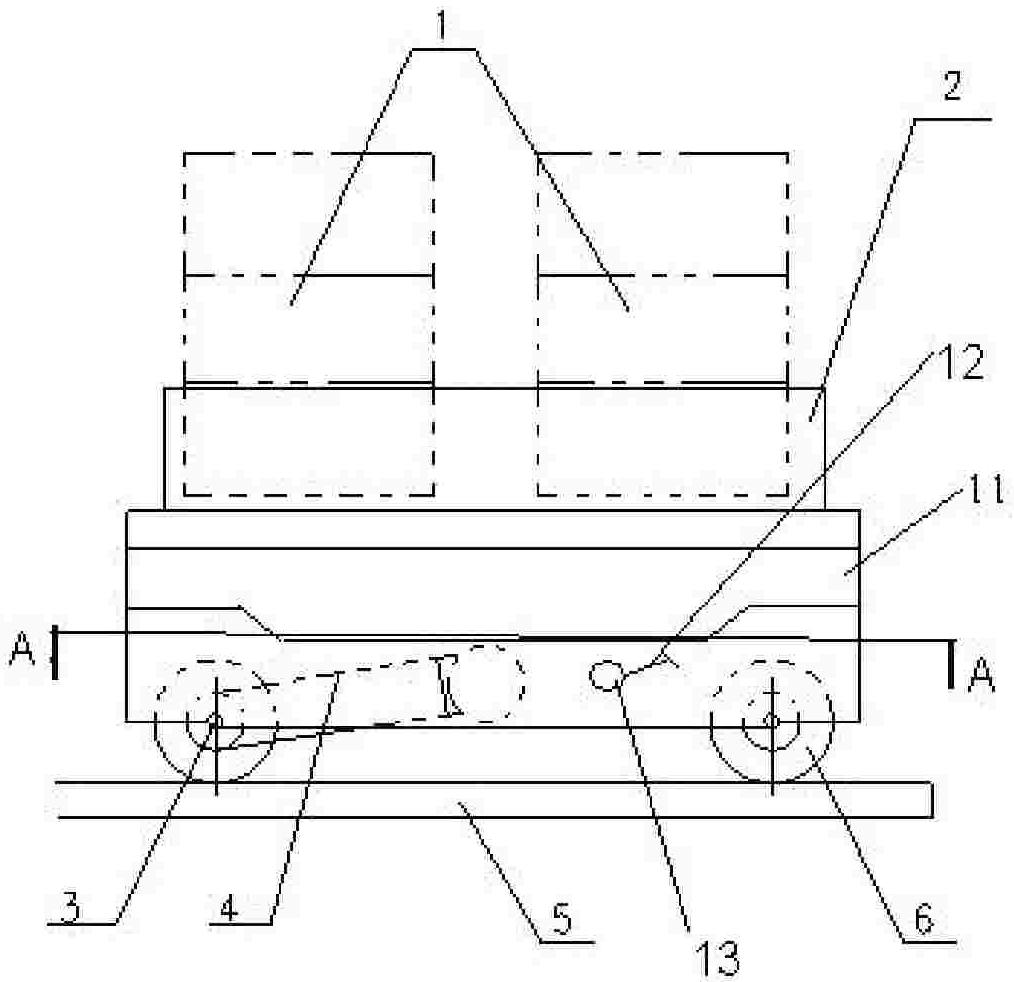

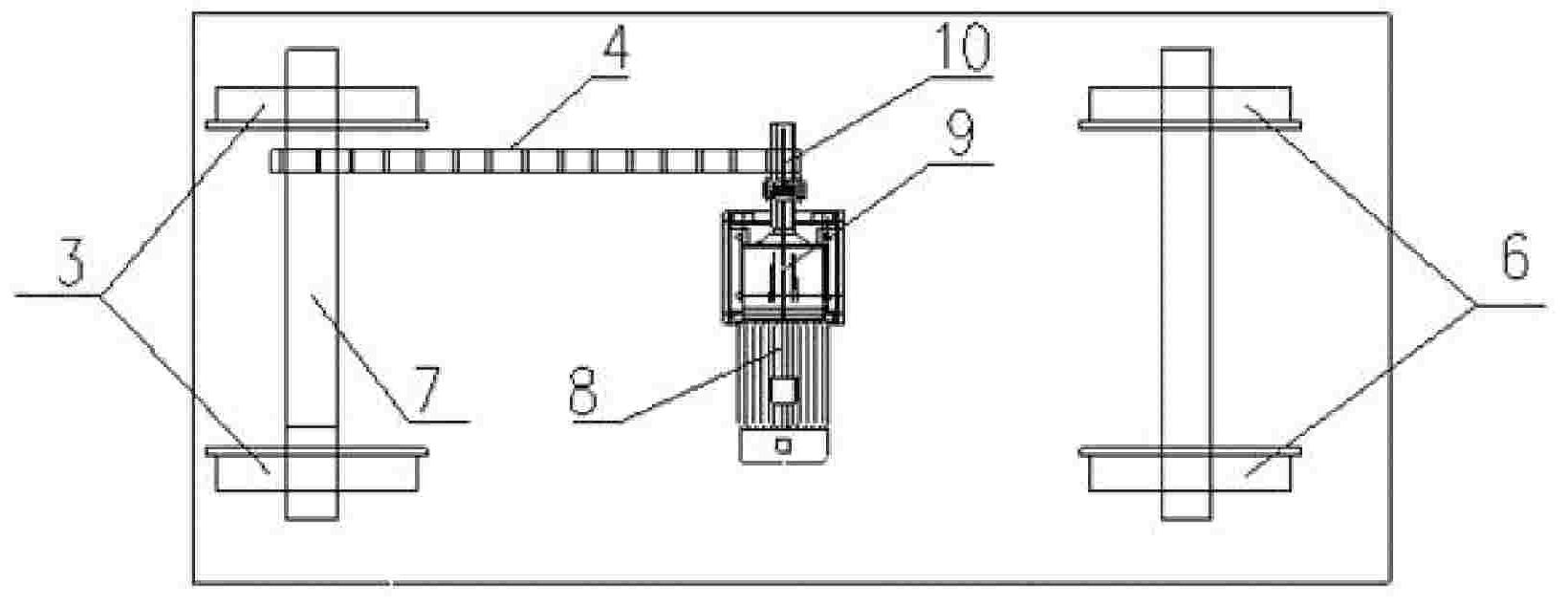

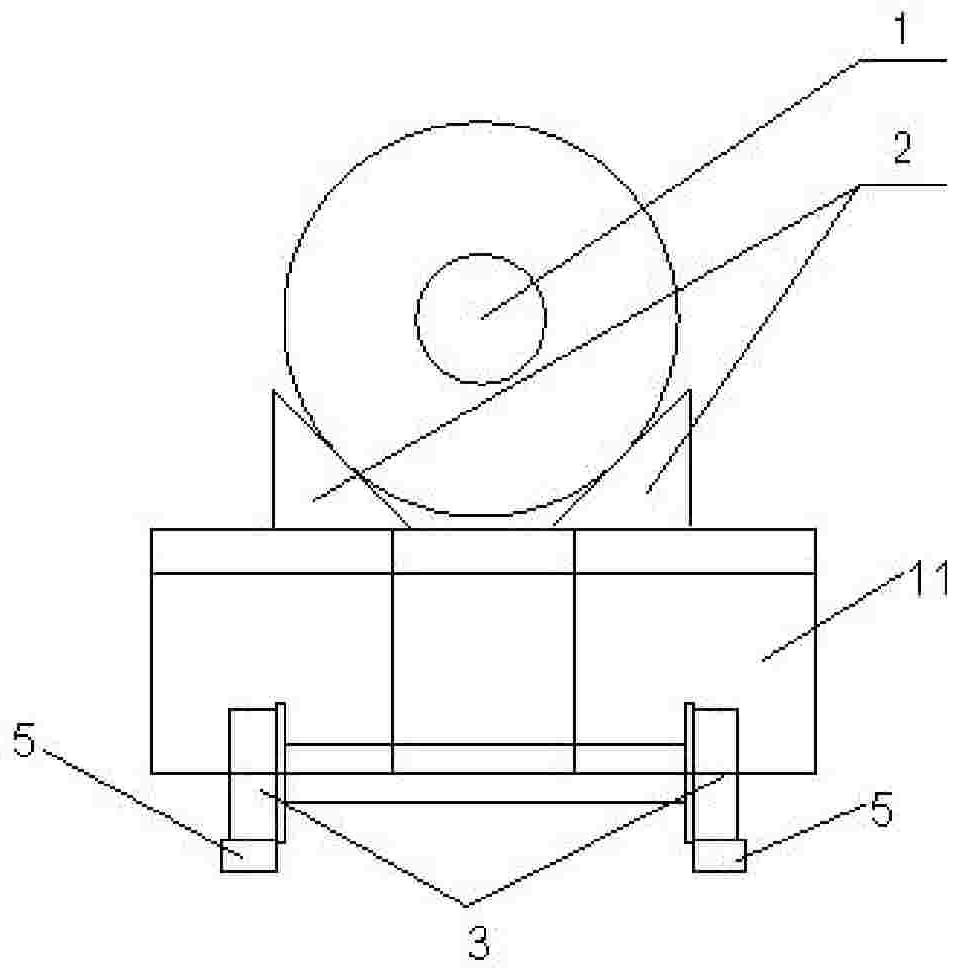

[0011] refer to figure 1 , figure 2 , image 3 , the upper part of the box body (11) is connected and installed with a V-shaped groove body (2), and its lower part is sequentially connected and installed with the main drive shaft (7), the main drive wheel (3), the chain (4), the sprocket coupling (10), Speed reducer (9), transmission motor (8), driven wheel (6), connect installation handle (12) and manual button (13) at casing (11) side then, assemble and form. During use, the transport vehicle of the present invention is installed on the track (5) fixed on the ground, and the steel coil (1) is hoisted into the V-shaped trough (2) of the transport vehicle, and the V-shaped trough (2) is designed The V-shaped groove plays the role of stabilizing the steel coil. The present invention adopts a wireless power system. Firstly, the 380v power supply is converted into a 36v safe voltage, and a circuit is formed through the sliding contact between the slider on the trolley and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com