Method for preparing microporous polyurethane elastomer

A technology of microcellular elastomer and polyurethane, which is applied in the field of preparation of polyurethane microcellular elastomer, can solve the problems of long production cycle, high cost of raw materials, and high requirements for machinery and equipment, and achieve easy operation, low price, lower storage temperature and storage cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

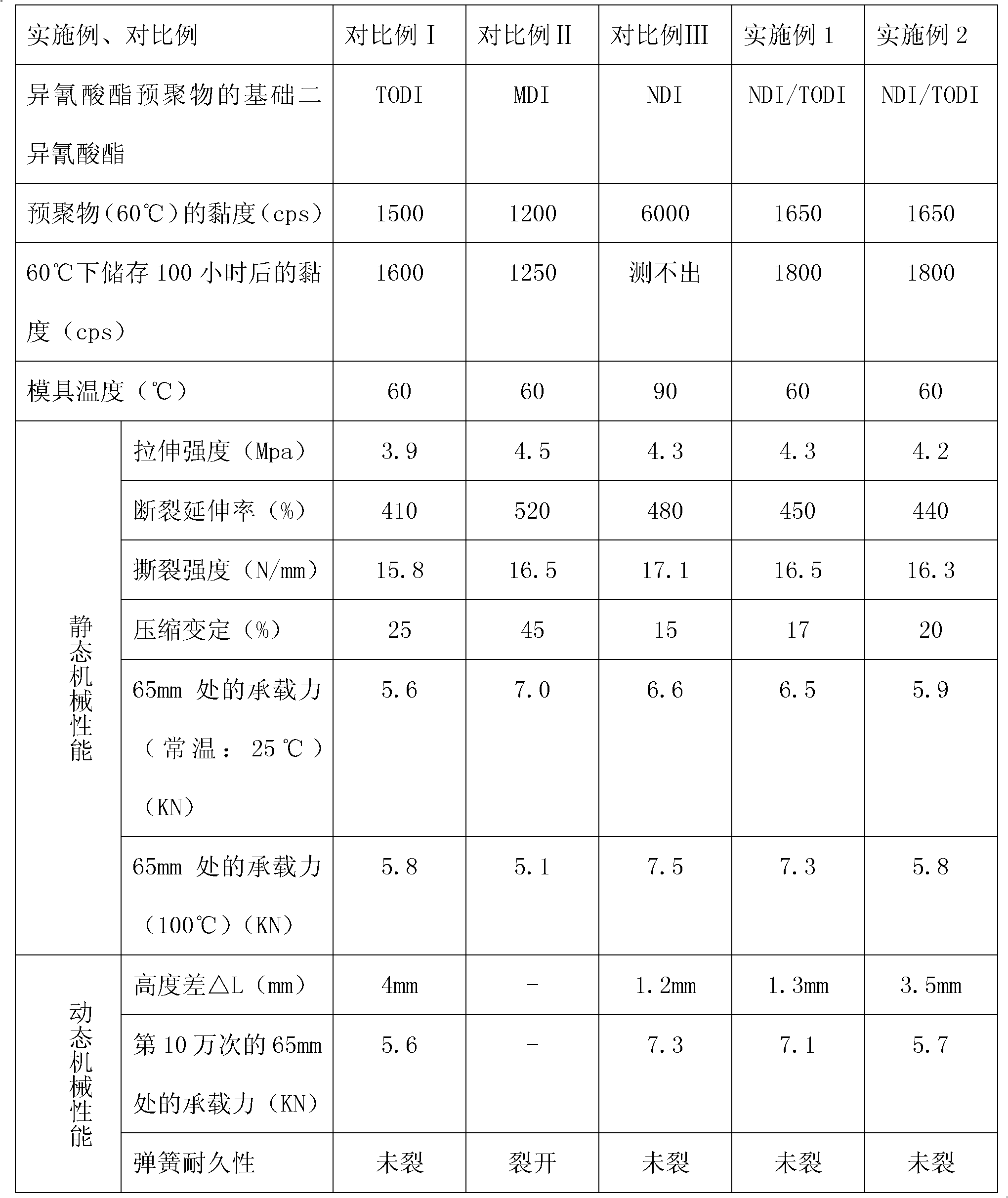

Examples

Embodiment 1

[0030] After melting 100 parts by weight of polyethylene glycol adipate polyol with a number average molecular weight Mn of 2000 and a hydroxyl value of 56 mgKOH / g at 127° C., add 21 parts by weight of NDI (active component NCO / OH molar ratio For 2), after keeping this temperature for 15min, a clear and transparent polyurethane prepolymer was obtained. Then 26.4 parts by weight of TODI (TODI / NDI molar ratio is 1) was added and cooled to 60°C while stirring to obtain a transparent and clear mixed prepolymer. In addition, 4 parts by weight of water, 2 parts by weight of foam stabilizer, catalyst 0.3 parts by weight, these were stirred and mixed for 2 hours to obtain a chain extender.

[0031] Under the above-mentioned temperature conditions, the mixed prepolymer and the chain extender were mixed and stirred at a weight ratio of 100:50, and a foaming reaction was carried out, and then a post-aging treatment was performed to obtain a sample for evaluation.

Embodiment 2

[0033] For Example 1, 3 parts by weight of water and 5 parts by weight of 1,4-butanediol were used instead of 4 parts by weight of water in the chain extender component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com