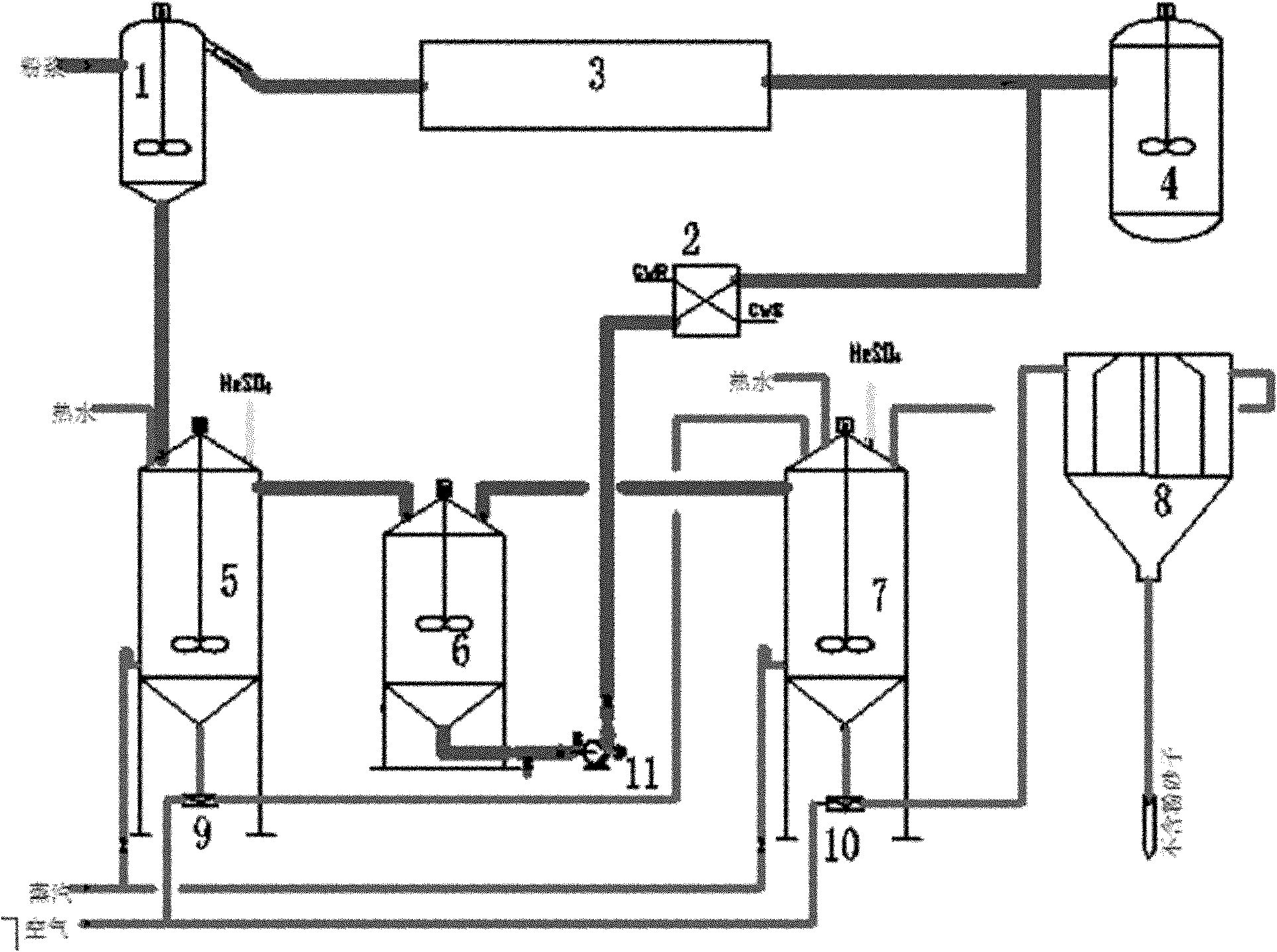

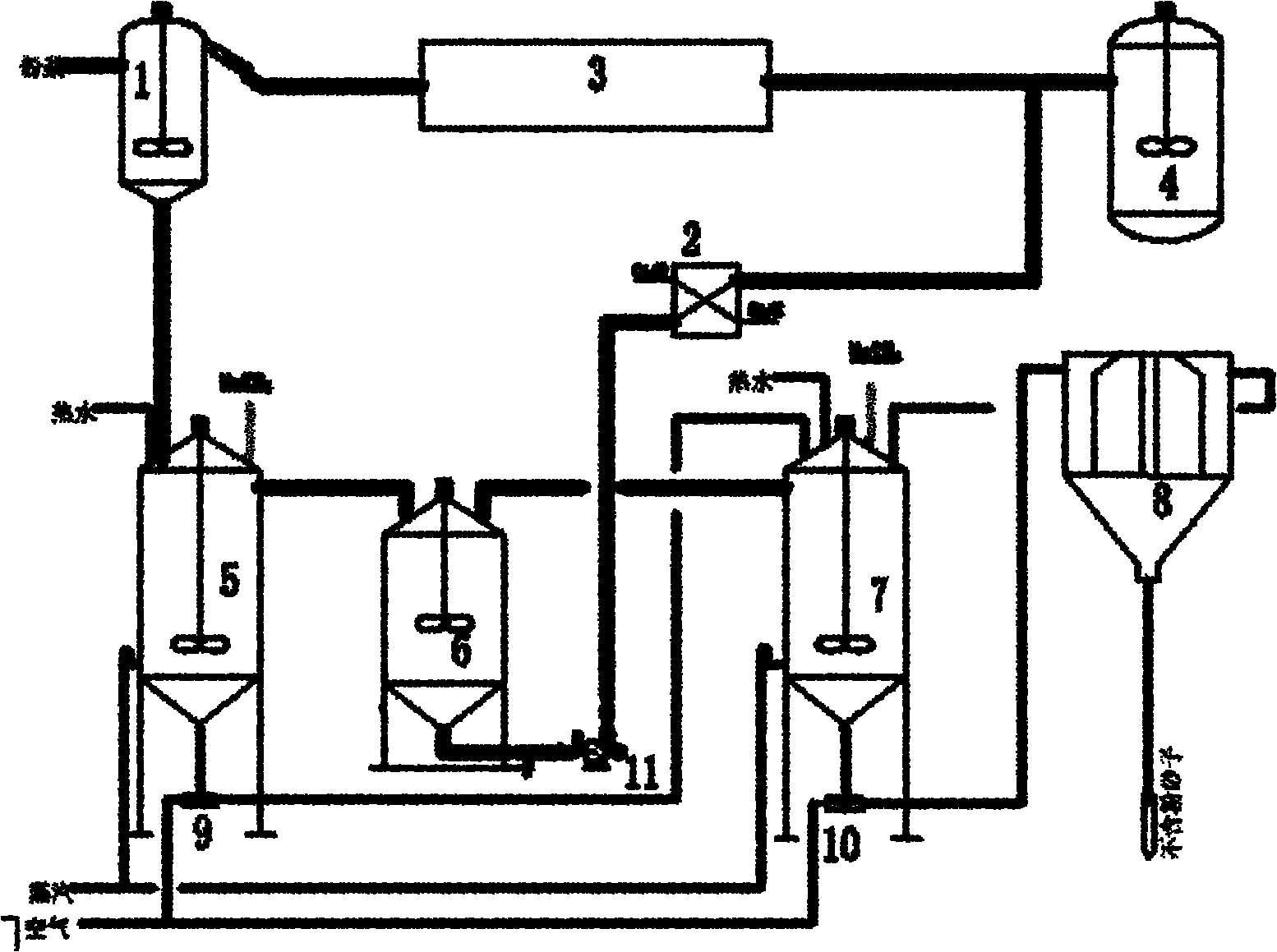

Device and method for acidifying raw materials and removing sand in ethanol production

A technology for raw materials and ethanol, which is applied in the field of devices for acidification and sand removal of raw materials, can solve the problems of difficult sand removal and incomplete sand removal, and achieves the effect of saving operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Take the annual output of 50,000 tons of ethanol plant in a certain cassava alcohol factory as an example, further illustrate the technological process of the present invention:

[0032] The cassava starch (still containing 5% fine sand) that removes coarse sand from pulverizing section enters mixing tank 1, and mixing tank 1 has stirring, and its working temperature is 50 ℃, air pressure normal pressure. After the cassava starch is stirred and mixed, the sand-containing powder slurry (accounting for 20% of the cassava starch quality) settles at the bottom of the mixing tank 1, and enters the middle part of the primary acidification tank 5 by means of the potential difference.

[0033] After the liquid level of the first-stage acidification tank 5 rises, steam is introduced to heat it so that the temperature in the tank reaches 90°C, the air pressure is normal pressure, and the stirring is started. At the same time, sulfuric acid with a concentration of 50% is added. 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com