Intelligent electrohydraulic flow servo valve

A servo valve, intelligent technology, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the static indicators such as servo valve symmetry, linearity, etc., which have not been significantly improved, position sensor parameters and closed-loop control Parameters cannot be adjusted by themselves, there is no intelligent fault diagnosis, self-adaptation and other problems, to achieve the effect of realizing intelligent control and self-adaptation ability, flexible setting and adjustment of control parameters, and improving anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

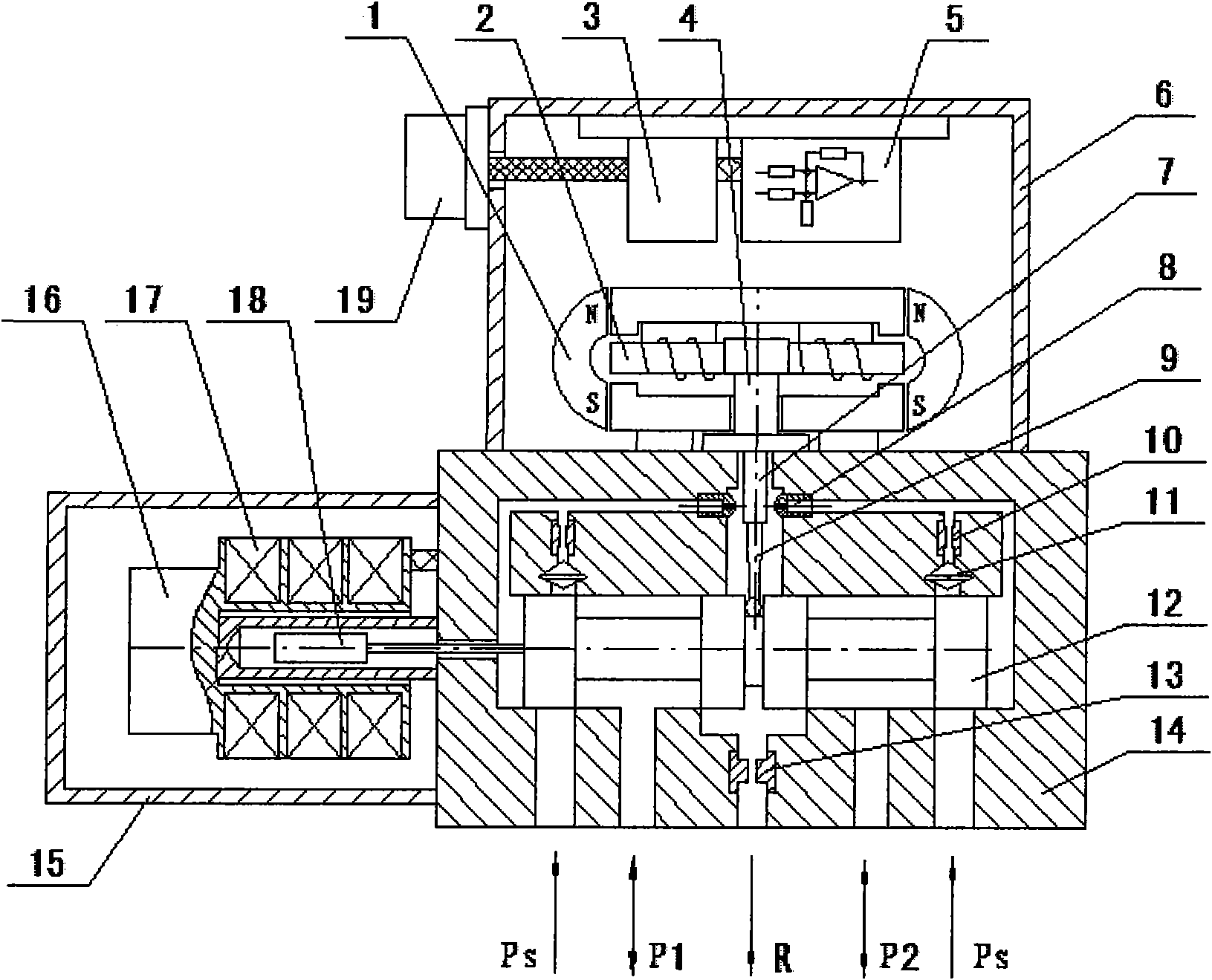

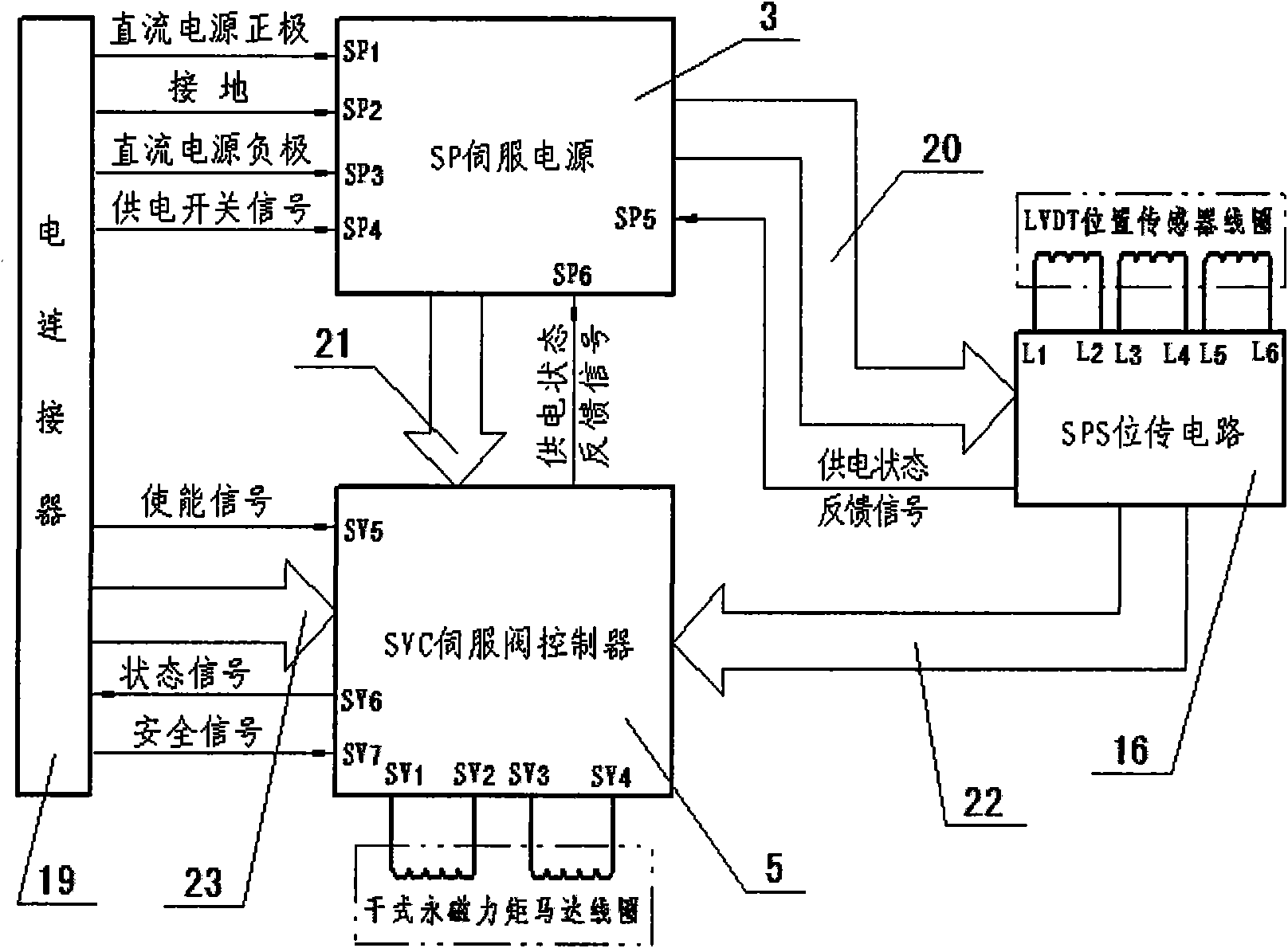

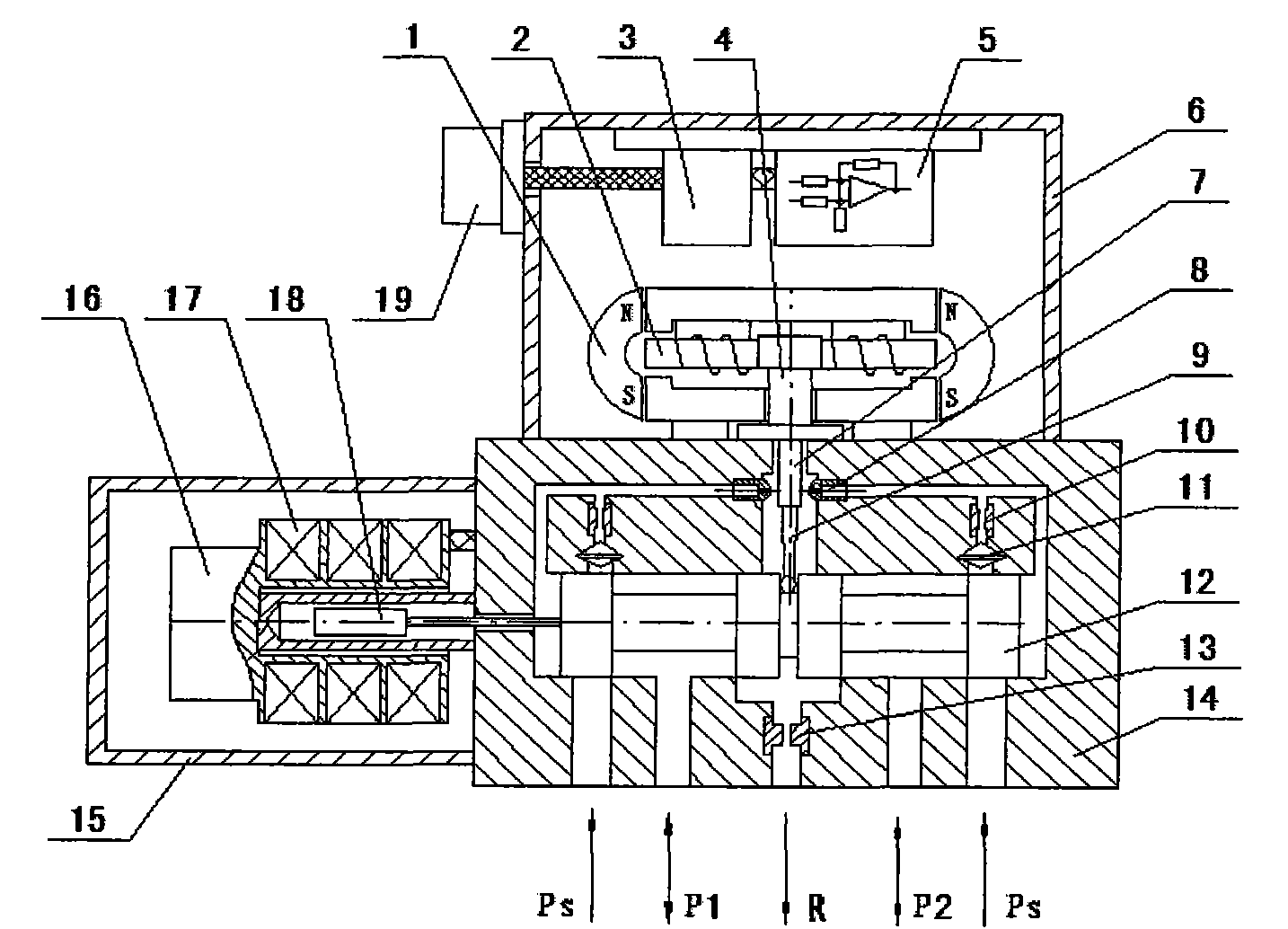

[0018] exist figure 1 In the shown embodiment, the SP servo power supply 3 and the SVC servo valve controller 5 are installed and fixed on the upper cover 6 of the electro-hydraulic flow servo valve with screws; the dry permanent magnet torque motor 1 and the gear assembly 2 are arranged on the SP The lower end of the servo power supply 3 and the SVC servo valve controller 5 is installed and fixed on the valve body 14 below the SP servo power supply 3 and the SVC servo valve controller 5; The flow chamber and the control chambers at both ends of the force feedback centering slide valve 12 are connected; the force feedback centering slide valve 12 is respectively connected with the high pressure oil chamber, the load oil chamber and the oil return chamber through the oil circuit; the dry permanent magnet torque motor The gear assembly 2 in 1 is connected with the feedback lever 9 and the force feedback centering slide valve 12; the iron core 18 in the LVDT high-precision positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com