Testing device and method for dynamic characteristic of sliding combination surface

A technology for dynamic characteristics and testing devices, which is used in measurement devices, vibration testing, and testing of machine/structural components. error, the effect of improving the recognition accuracy

Inactive Publication Date: 2011-06-15

BEIJING UNIV OF TECH

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional machine tool design method cannot establish an accurate dynamic model of the machine tool structure, which seriously hinders the dynamic optimization design of the machine tool structure. One of the important reasons for the inability to establish an accurate model is the inability to accurately identify the characteristic parameters of the machine tool joint surface.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

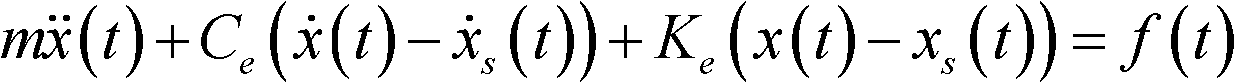

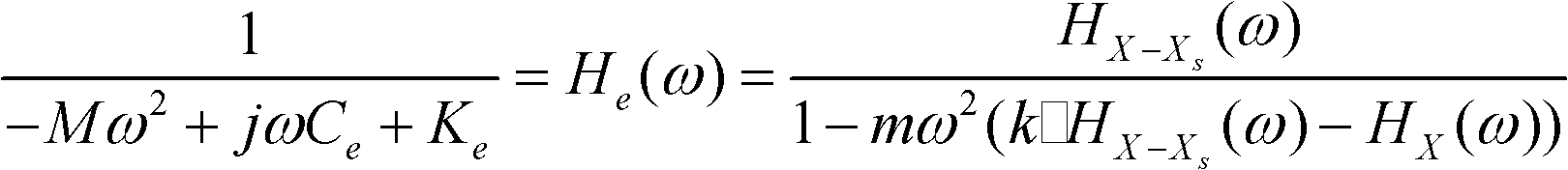

The invention discloses a testing device and method for the dynamic characteristic of a sliding combination surface. The testing device comprises an operation device and a data collecting, analyzing and processing system of an experiment device, wherein the operation device is characterized in that a single motor drives a bridge plate and a vibration exciter bracket to synchronously move; in the moving process, a vibration excitation test is carried out; the operation device comprises a substrate, a bridge plate guide rail pair, the synchronous moving device of the vibration exciter, a normal pressurization device, a tangential pressurization device and a driving actuation device; the data collecting, analyzing and processing system of the experiment device comprises a signal acquisition module, a signal path module and a signal analyzing and processing module. The vibration excitation experiment can be realized in the moving process. Motor speed is adjustable; the applied pressure can change within the required range to identify joint surface parameters under different pressure states; and a tangential guide block is a replaceable piece, and the characteristic parameters of a joint part under different materials of steel and cast iron and various surface roughness degrees can be tested. Powerful guarantee is provided for the identification precision of the joint surface experiment can be provided by the high-speed and high-efficiency data collecting, analyzing and processing system.

Description

Testing device and testing method for dynamic characteristics of sliding joint surface technical field The invention relates to a test system and a test method for acquiring basic characteristic data of a joint surface in a sliding state, and is used for testing dynamic characteristic parameters of a joint part in a sliding state. Background technique The machine tool manufacturing industry is the heart of the machinery manufacturing industry and the "mother machine" of equipment. The possession and performance level of high-speed, high-efficiency, high-precision, and high-reliability CNC machine tools has become an important symbol to measure the level of a country's machinery manufacturing industry. CNC machine tools are precision, efficient, flexible, and automated processing equipment that require very high precision. The mechanical structure is very complicated. It is composed of various parts according to certain specific requirements. There are various joint surfaces...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M7/02

Inventor 伍良生王泽林肖毅川马建峰晁慧泉

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com