Device and method for testing superconductivity of three-dimensional low-temperature superconducting thin film coil

A technology of low-temperature superconducting and thin-film coils, which is applied in the measurement of magnetic properties, etc., and can solve the problem of insufficient experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

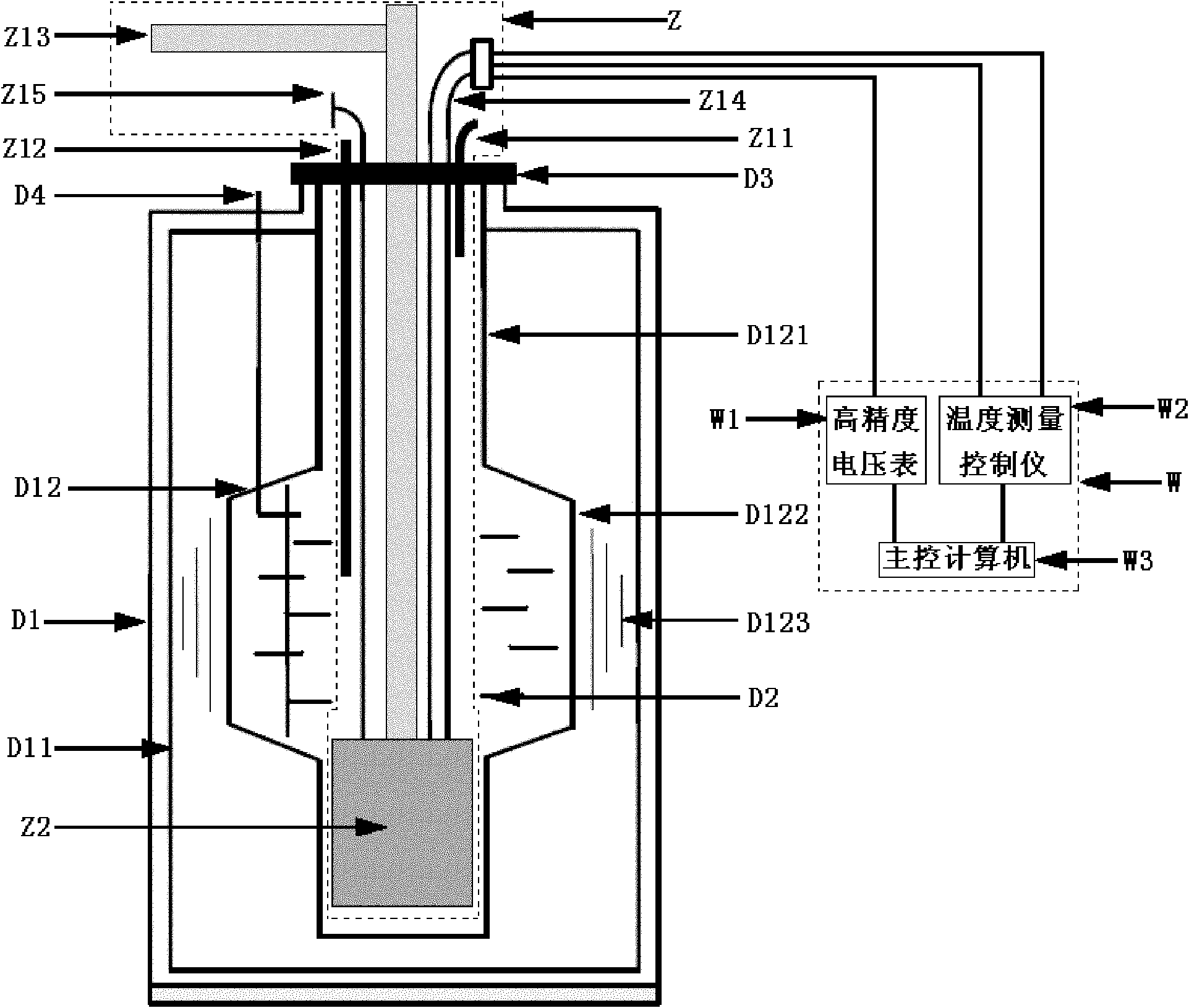

[0034] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, this embodiment includes low temperature environment system D, vacuum environment system Z, test work system C and external measurement control system W;

[0035] The external measurement control system W includes a high-precision voltmeter W1, a temperature measurement control instrument W2 and a main control computer W3;

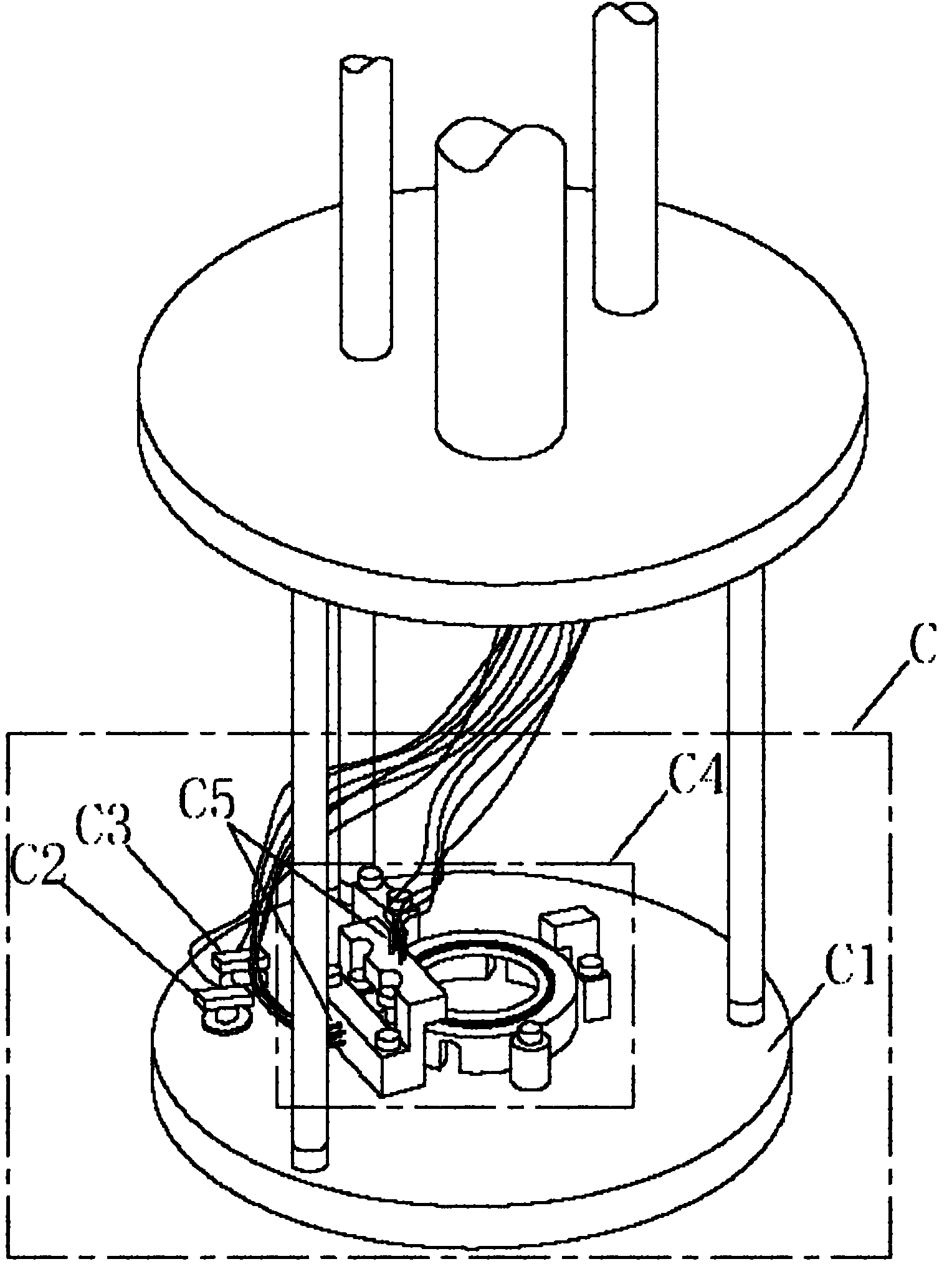

[0036] The test working system C includes a test disc-shaped copper plate C1, a thermometer C2, a heater C3, a clamping coil assembly C4 and at least one compression spring probe C5;

[0037] Low temperature environment system D includes Dewar bottle D1, liquid helium D2 and Dewar bottle cap D3;

[0038] The vacuum environment system Z includes a vacuum tank Z2 and five metal pipes,

[0039] The five metal pipes are the exhaust pipe Z11, the coolant injection pipe Z12, the vacuum pump pipe Z13, the first electrical interface sealing...

specific Embodiment approach 2

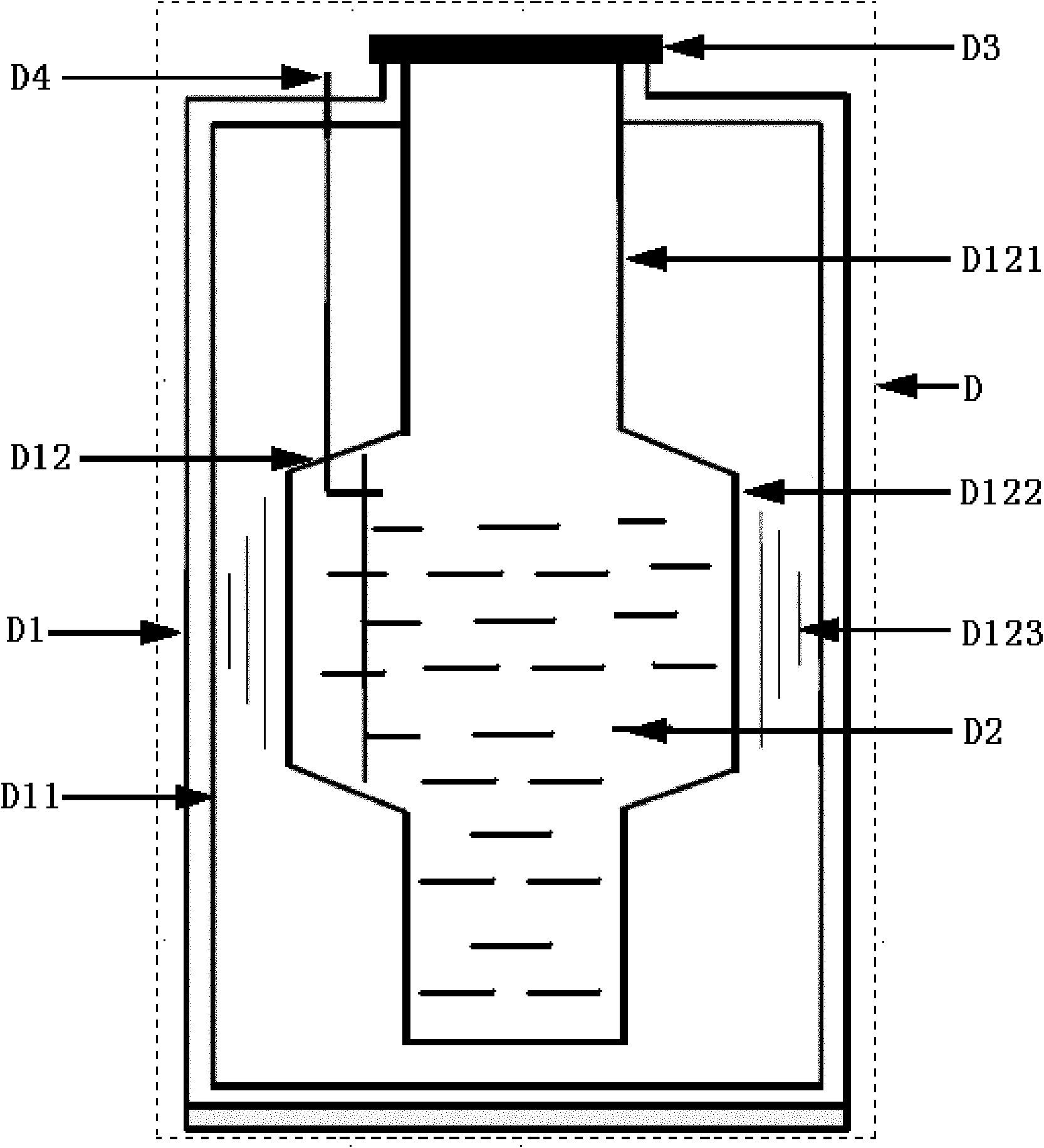

[0051] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the Dewar bottle D1 has an inner and outer two-layer shell structure, the outer shell D11 is a cylindrical metal tank with an open upper end, and the inner shell D12 is a three-section cylindrical inner shell. The connection forms the tank body, and the cavity between the inner and outer shells is a vacuum. The main purpose is to make the low temperature environment inside the Dewar D1 well insulated from the room temperature environment outside.

[0052] The three-section cylindrical inner shells are successively the upper cylindrical inner shell D121, the middle cylindrical inner shell D122 and the lower cylindrical inner shell D123 from top to bottom, and the three-section cylindrical inner shells hold the liquid in the Dewar bottle D1 The helium space is divided into a low heat conduction pipe neck...

specific Embodiment approach 3

[0059] Specific implementation mode three: combination image 3 and Figure 4 Describe this embodiment. The first difference between this embodiment and the specific embodiment is that the clamping coil assembly C4 includes a plane positioning block C41, a cylindrical positioning pin C42 and a clip C43 with a spring piece, wherein the plane positioning block C41 is located on the measured The upper part of one side of the three-dimensional low-temperature superconducting thin-film coil is provided with a boss, which is used to block the upward transmission displacement of the measured three-dimensional low-temperature superconducting thin-film coil due to vibration, which is made of G10 material; the cylindrical positioning pin C42 and the The clip C43 of the spring sheet is made of copper, and the plane positioning block C41, the cylindrical positioning pin C42 and the clip C43 with the spring sheet are respectively fixed on the test disc-shaped copper plate C1, and distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com