Welding coupler for first lens of laser

A coupler and laser technology, applied in the field of coupling devices, can solve problems affecting the performance and application range of semiconductor laser modules, reducing the final coupling power of modules, and reducing production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

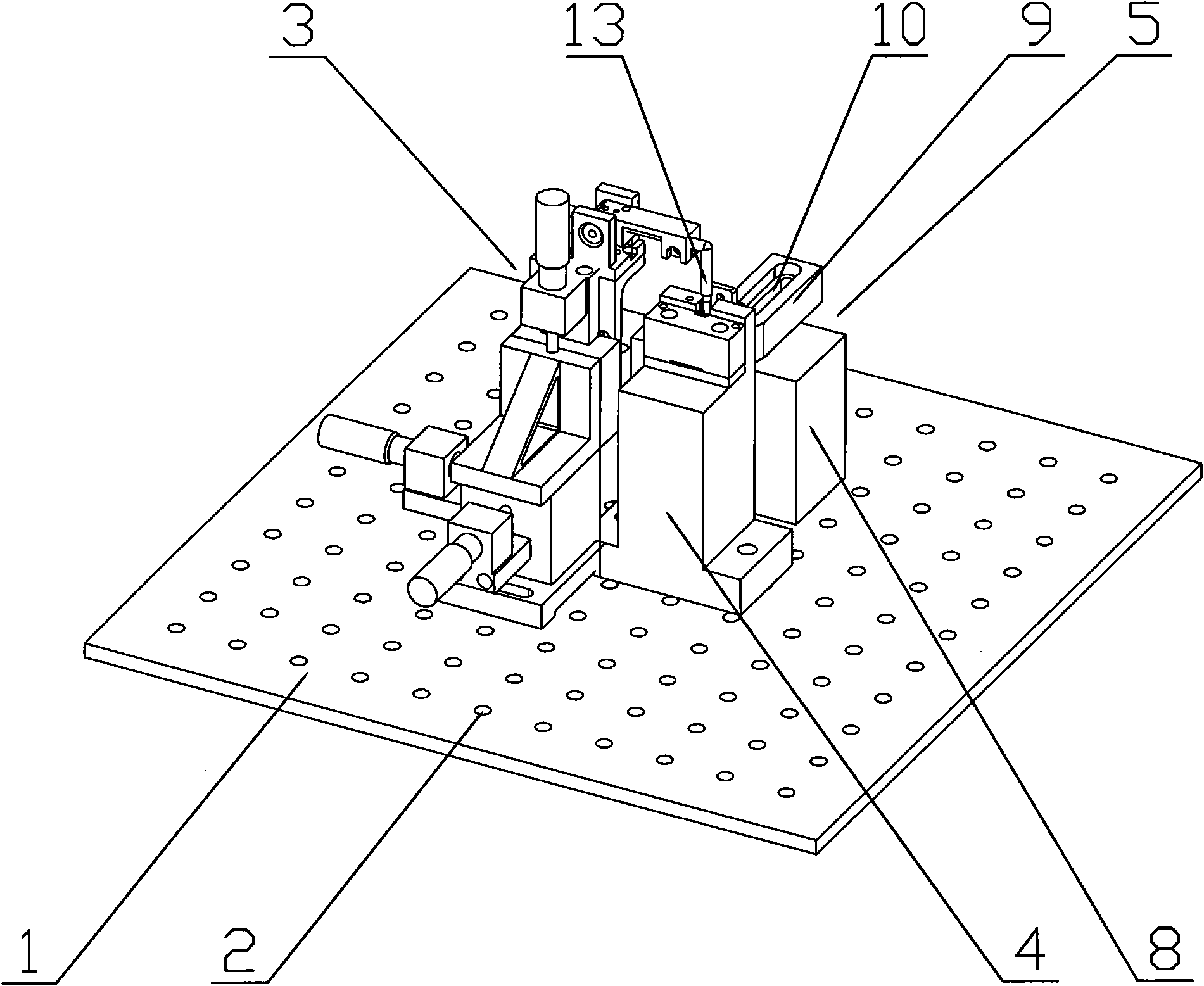

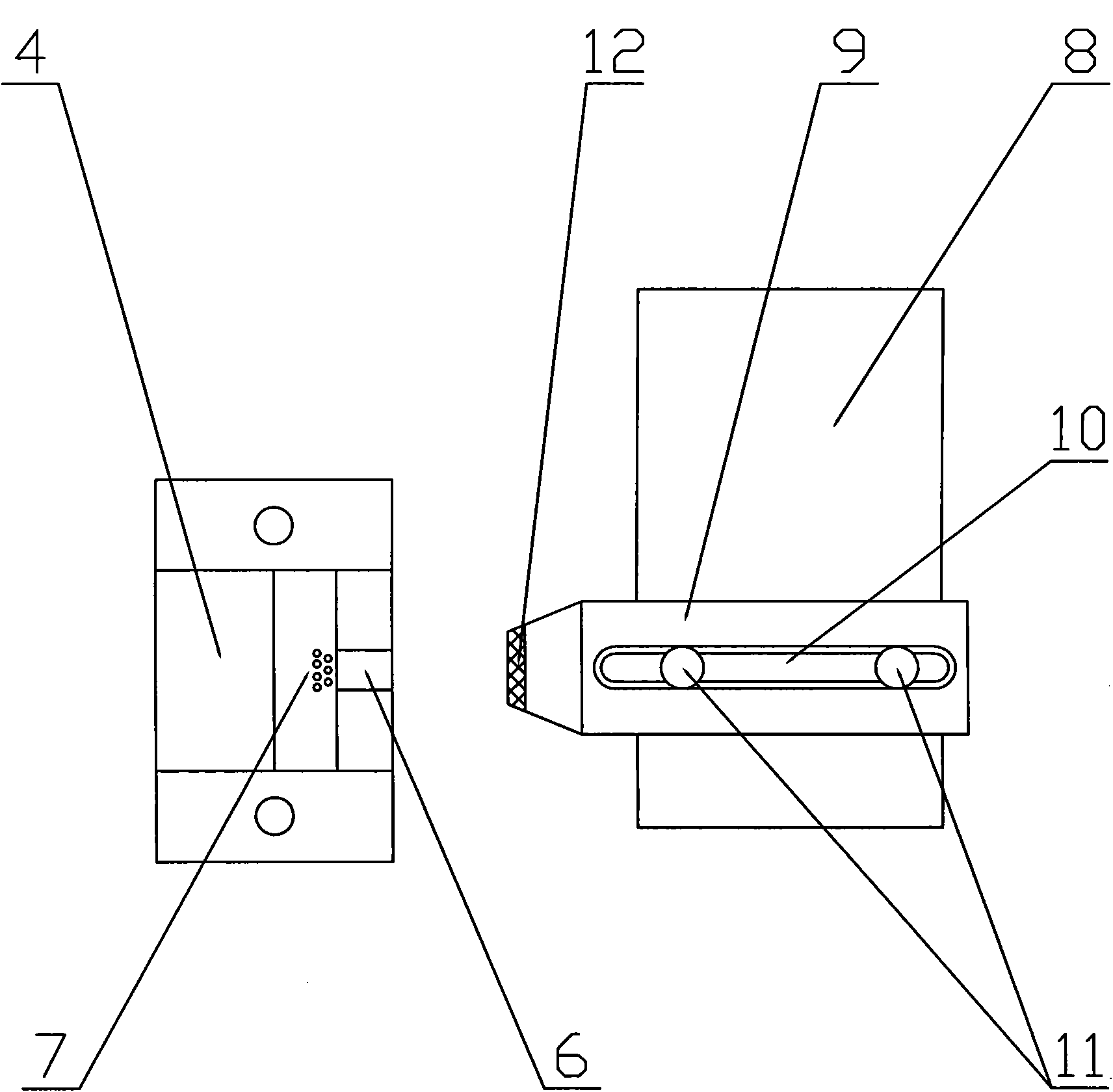

[0009] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 Shown: a welding coupler for the first lens of a laser, which includes a base plate 1 as a base, and a plurality of fixing holes are opened on the base plate 1, through these fixing holes 2, a three-dimensional adjustment platform 3, a module fixing table 4 and an optical path The simulation table 5 is fixedly connected to the substrate 1; the working end 13 of the three-dimensional adjustment platform 3 is controlled by a vacuum pump arranged at the far end, and the first lens is adsorbed on the working end 13; a module card slot 6 is arranged on the upper end of the module fixing table 4, For fixing the module, a plurality of module power-on pin slots 7 are arranged near the module card slot 6, and the pins on the module are plugged into the module power-on pin slots 7; the optical path simulation table 5 consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com