Process for preparing acetoacetic ester

A technology of acetoacetate and preparation process, which is applied in the preparation of ketene/polyketene, organic chemistry and other directions, can solve the problems such as lower acetoacetate product yield, small production scale, complicated operation and the like, and achieves expansion of production. Ability, easy operation, avoid the effect of reaction deanhydride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

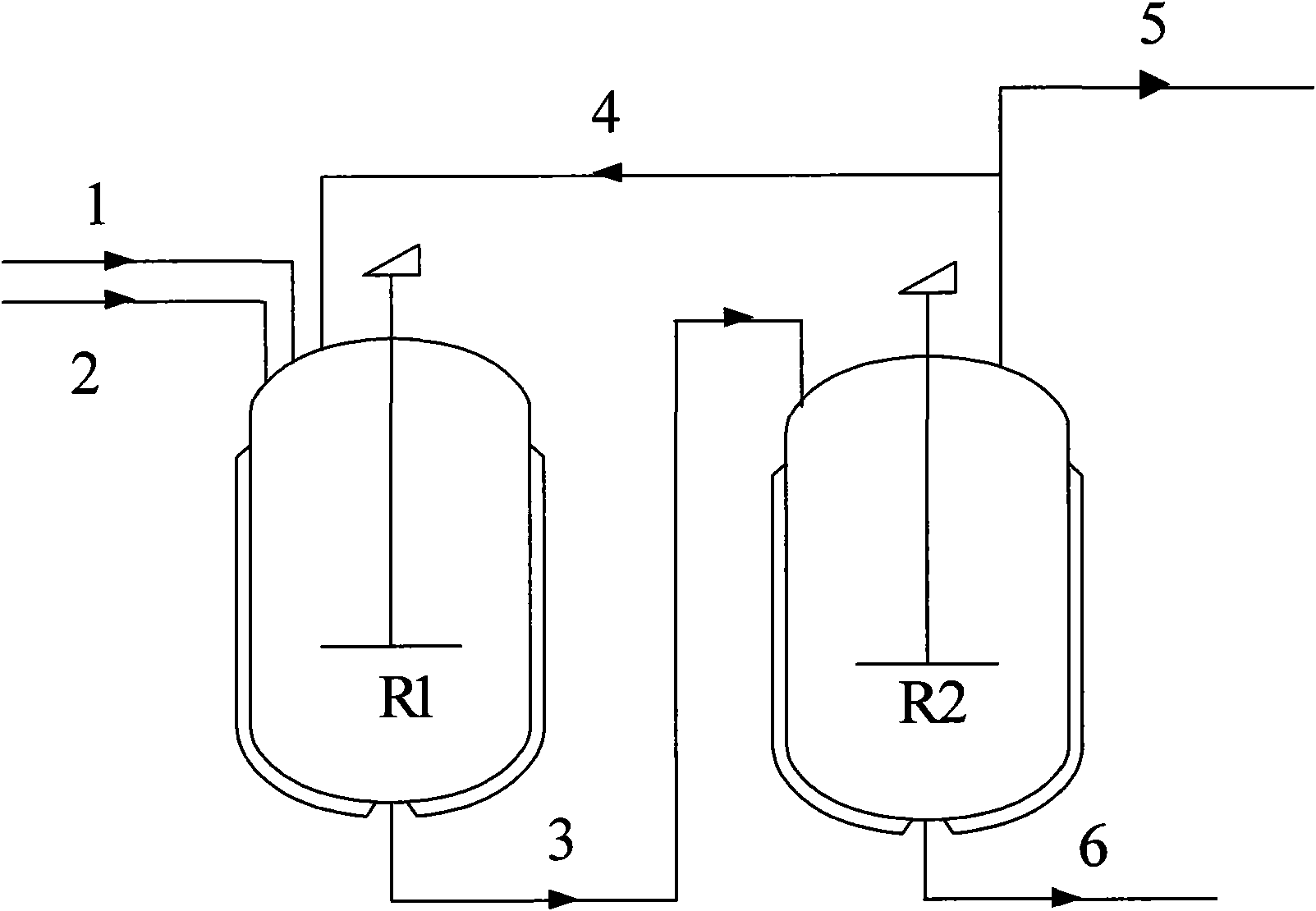

Method used

Image

Examples

Embodiment 1

[0029] Add 32g of methanol and 0.057g of catalyst diethylenetriamine into the reaction kettle, add diketene dropwise to react, establish the initial liquid level, add dropwise until the concentration of methanol in the initial reaction liquid is 5% by mass, start continuous feeding: methanol 1ml / min , wherein the catalyst content is 0.5%, refined diketene 1.5ml / min, light component circulation flow 0.8ml / min (wherein, the mass ratio of circulating material and discharging is 1: 5), the control reactor temperature is controlled at 95 ℃, Fine-tune the feed flow rate according to the concentration analysis results, and keep the concentration of methanol in the reaction liquid at 5% by mass; the output flow rate of the reactor is 2.5ml / min, and the temperature of the aging flash tank is controlled at 120°C, operated under normal pressure, and the aging flash is evaporated The output flow rate of the kettle is 2ml / min, and the crude ester liquid is analyzed, and the concentration of...

Embodiment 2

[0031] Add 32g of methanol and 0.057g of catalyst triethylenediamine into the reaction kettle, add diketene dropwise to react, establish the initial liquid level, add dropwise to the concentration of methanol in the initial reaction liquid is 10% by mass, start continuous feeding: methanol 1.5ml / min, wherein the catalyst content is 0.1%; refined diketene 2ml / min; light component circulation flow 0.3ml / min (wherein, the mass ratio of circulating material and discharging is 5: 1); control reactor temperature is controlled at 80 ℃, Fine-tune the feed flow rate according to the concentration analysis results, and keep the concentration of methanol in the reaction solution at 10% by mass; the output flow rate of the reactor is 3.5ml / min, the temperature of the aging flash tank is controlled at 105°C, and the operating pressure is 0.9atm (A) , the output flow rate of the aging flash tank is 2.5ml / min, the crude ester liquid is analyzed, the concentration of the crude ester is stable...

Embodiment 3

[0033] Add 32g of methanol and 0.057g of catalyst triethylamine to the reaction kettle, add diketene dropwise to react, establish the initial liquid level, add dropwise until the concentration of methanol in the initial reaction liquid is 20% by mass, start continuous feeding: methanol 1ml / min, Wherein the catalyst content is 0.35%; Refining diketene 1.5ml / min; Light component circulation flow 0.8ml / min (wherein, the mass ratio of circulating material and discharging is 2: 5); Control reactor temperature is controlled at 60 ℃, according to Concentration analysis results fine-tune the feed flow rate to keep the concentration of methanol in the reaction solution at 20% by mass; the output flow rate of the reactor is 2.5ml / min, the temperature of the aging flash tank is controlled at 130°C, and the aging flash tank is operated under normal pressure. The output flow rate is 2ml / min, and the crude ester liquid is analyzed. The concentration of the crude ester is stable at 96.8%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com