Composite pounder with buffering device

A buffer device and rammer technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of increasing machine maintenance costs, increasing machine failures, and reducing the service life of hydraulic systems, so as to achieve pile quality and High efficiency, increase the bearing capacity of single pile, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

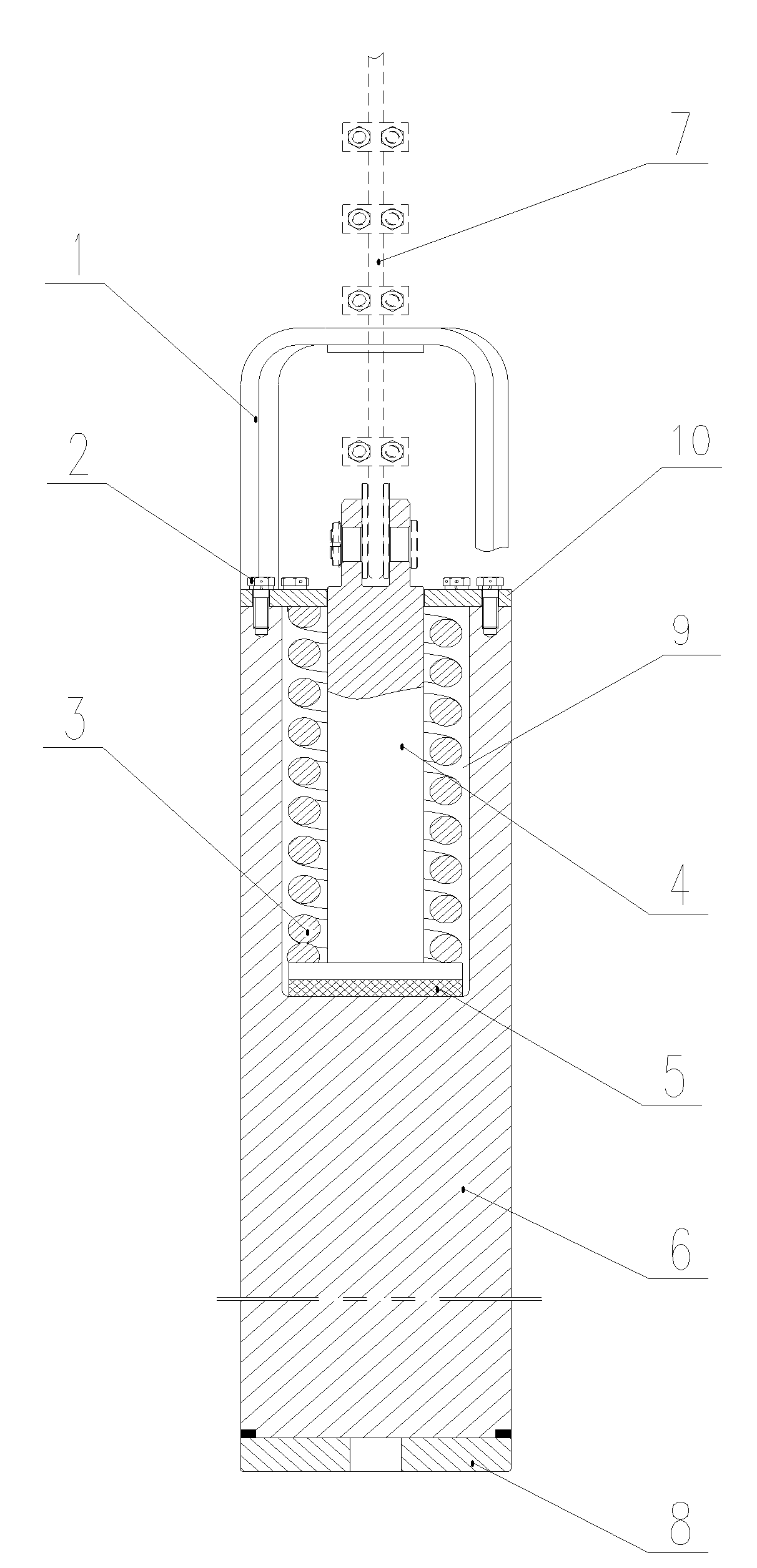

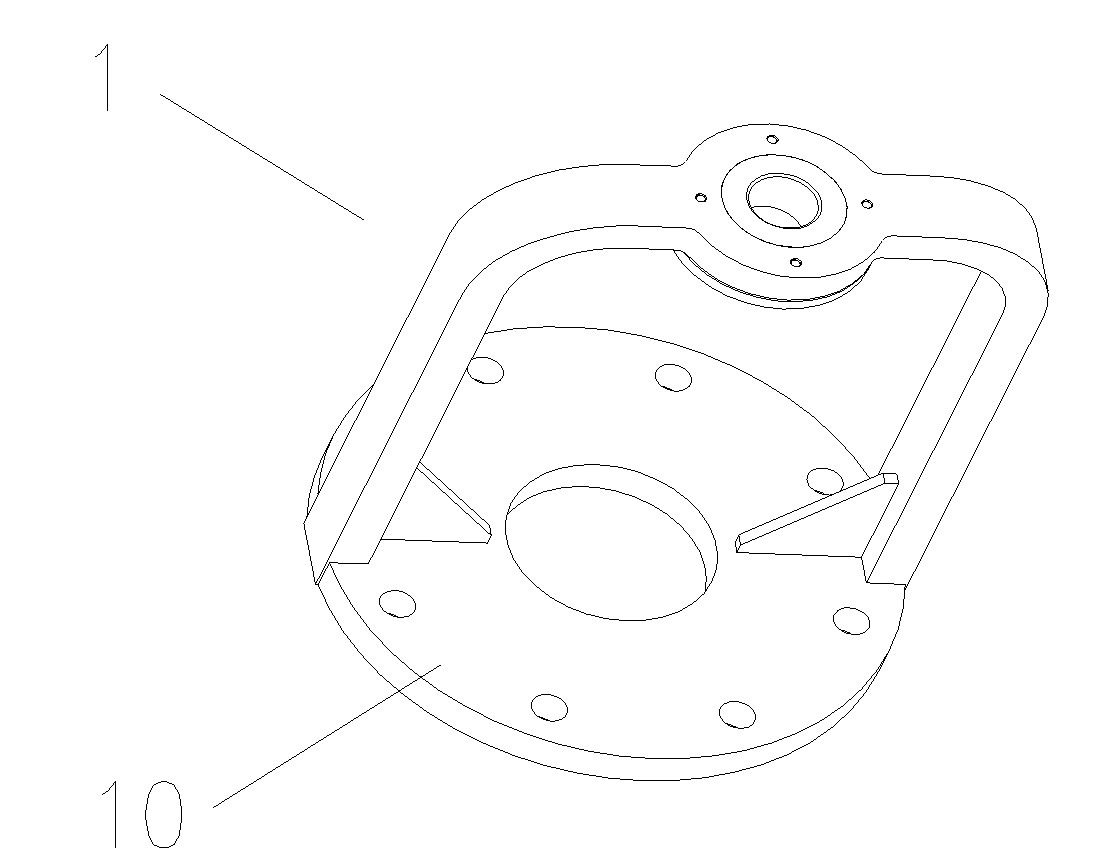

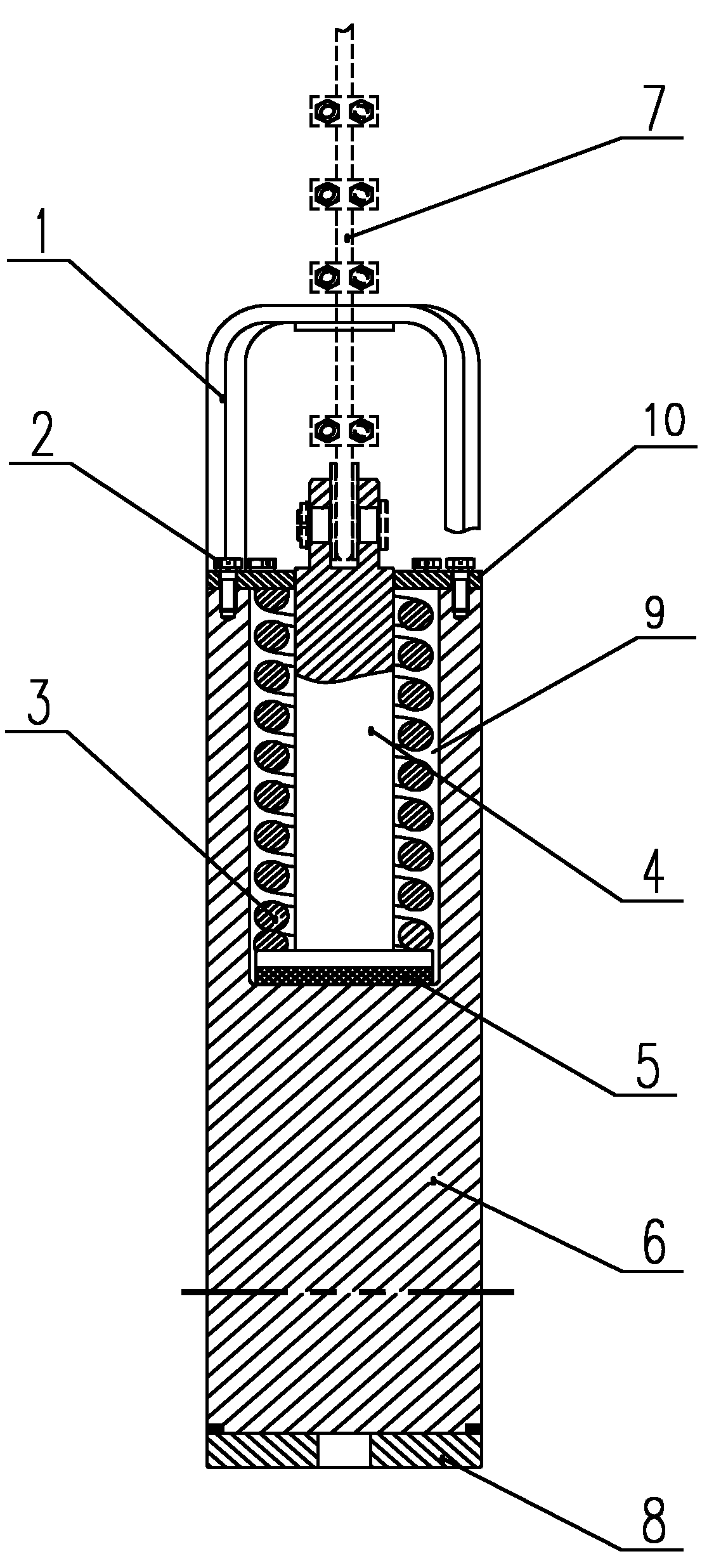

[0019] Such as figure 1 and figure 2 As shown, the top of the tamper 6 is provided with a counterbore 9, and the flange 10 at the bottom of the pull ring 1? The tamper 6 is connected as a whole by the bolt 2, a buffer pad 5 is placed at the bottom of the counterbore 9, the large end of the pull rod 4 is placed on the buffer pad 5, and a Buffer spring 3 is arranged, and the top of buffer spring 3 is fixed by the flange of the bottom of draw ring 1, and pull bar 4 passes buffer spring 3, and the end links to each other with wire rope 7, and wear-resisting hammer end 8 is welded on the end of rammer 6.

[0020] Such as figure 1 and figure 2 As shown, when the pile driver uses the rammer to tamp the bottom of the expanded hole, the composite rammer with its own buffer device is lifted to a certain height, and the rammer 6 falls freely through...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap