Flexible universal joint

A flexible and screw technology, used in elastic couplings, mechanical equipment, pivot connections, etc., can solve the problems of complex, single, easy to wear, loose and fall off the rigid universal joint manufacturing process, and achieve a simple structure, not easy to Wear, steering flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

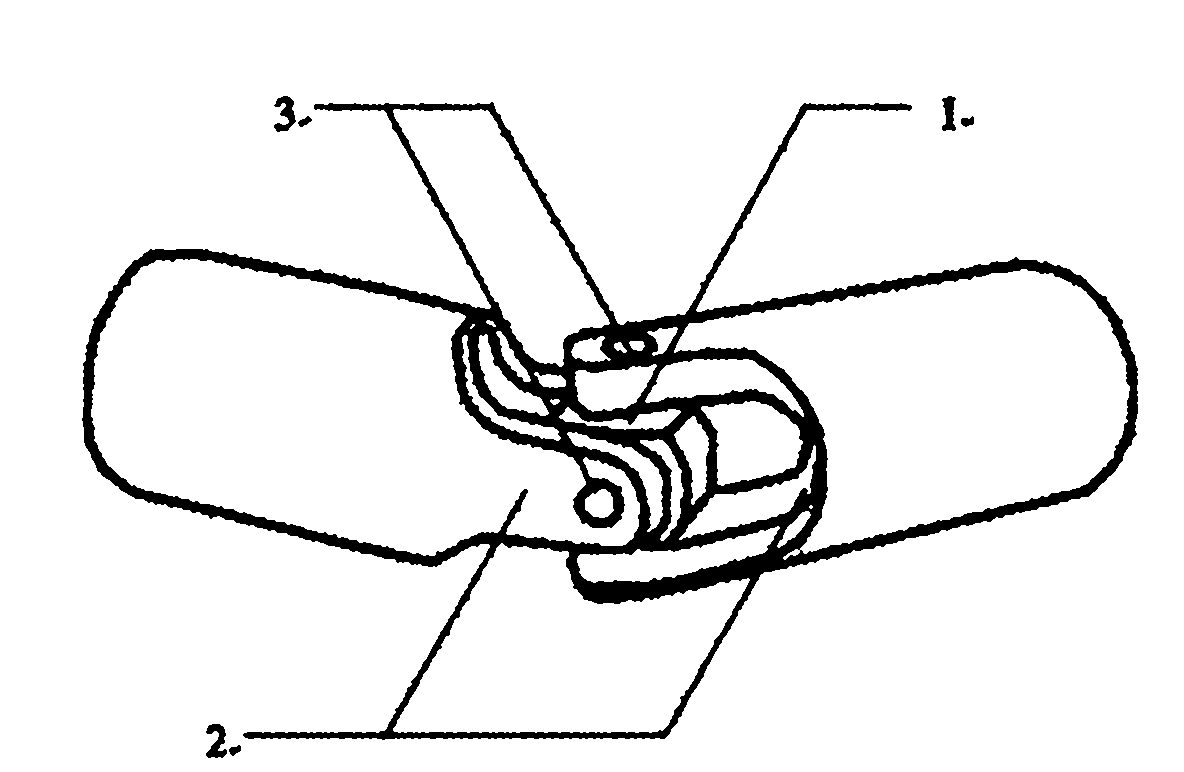

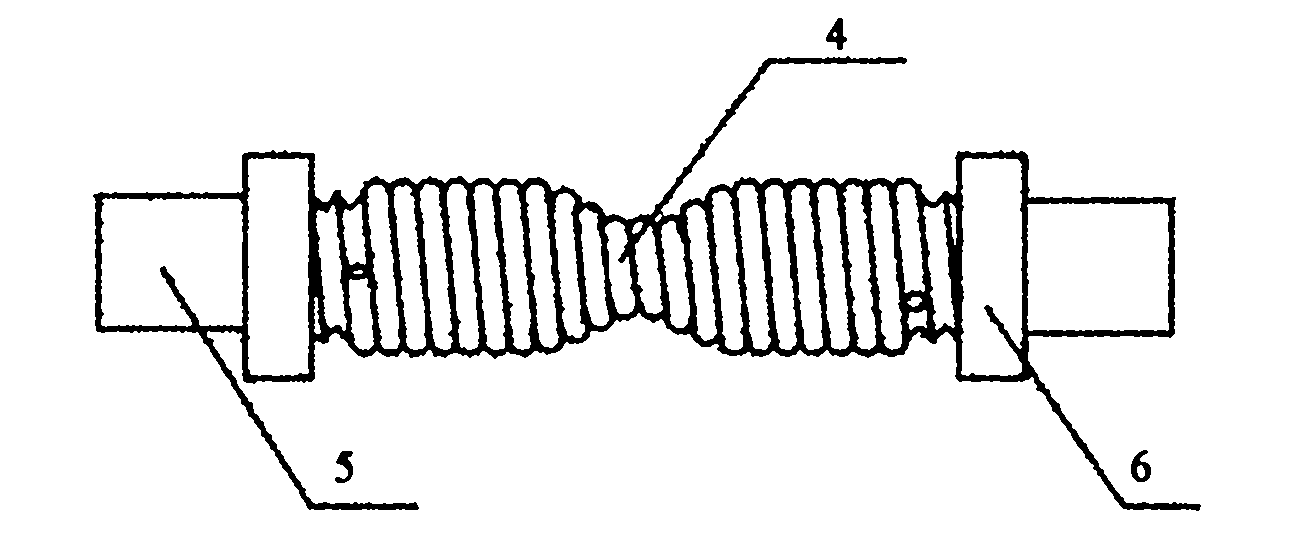

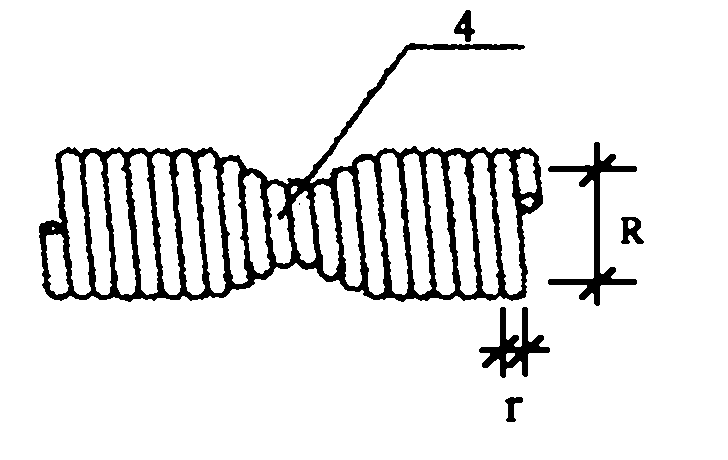

[0025] The present invention will be described below with reference to the accompanying drawings.

[0026] figure 2 It is a preferred structural schematic diagram of the flexible universal joint of the present invention, which is used to connect the connecting part of the first mechanical part and the connecting part of the second mechanical part. The flexible universal joint includes a spring 4, a first screw 5 and a second mechanical part. Screw 6, wherein, the schematic structural diagram of spring 4 is as follows image 3 As shown, the structural schematic diagram of the first screw 5 and the second screw 6 is as follows Figure 4 shown. The spring 4 is an extension spring, including the left, middle and right sections that are continuously distributed in sequence, and is an hourglass type with a thin middle section, a thick left section and a thick right section, that is, the spring 4 is an hourglass stretch with a thin middle and thick sides. Spring, the left and rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com