Three-dimensional vector hydrophone

A three-dimensional vector, hydrophone technology, applied in instruments, measurement devices, radio wave measurement systems, etc., can solve problems such as unfavorable miniaturization, difficulty in mass production, etc., and achieve simple structure, low processing cost, easy production and batch production. The effect of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

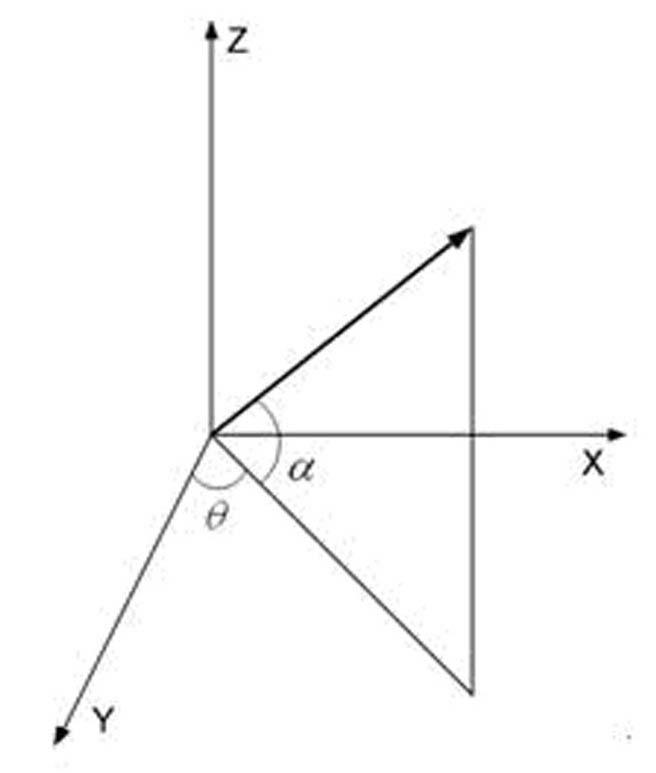

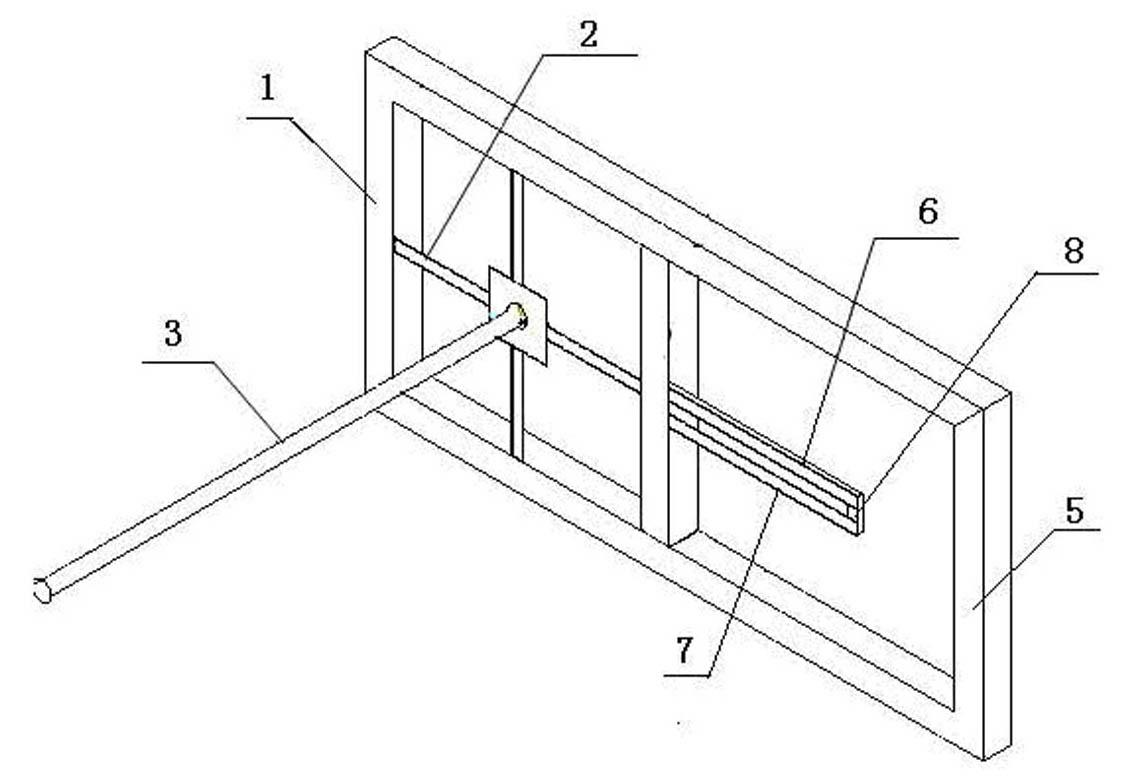

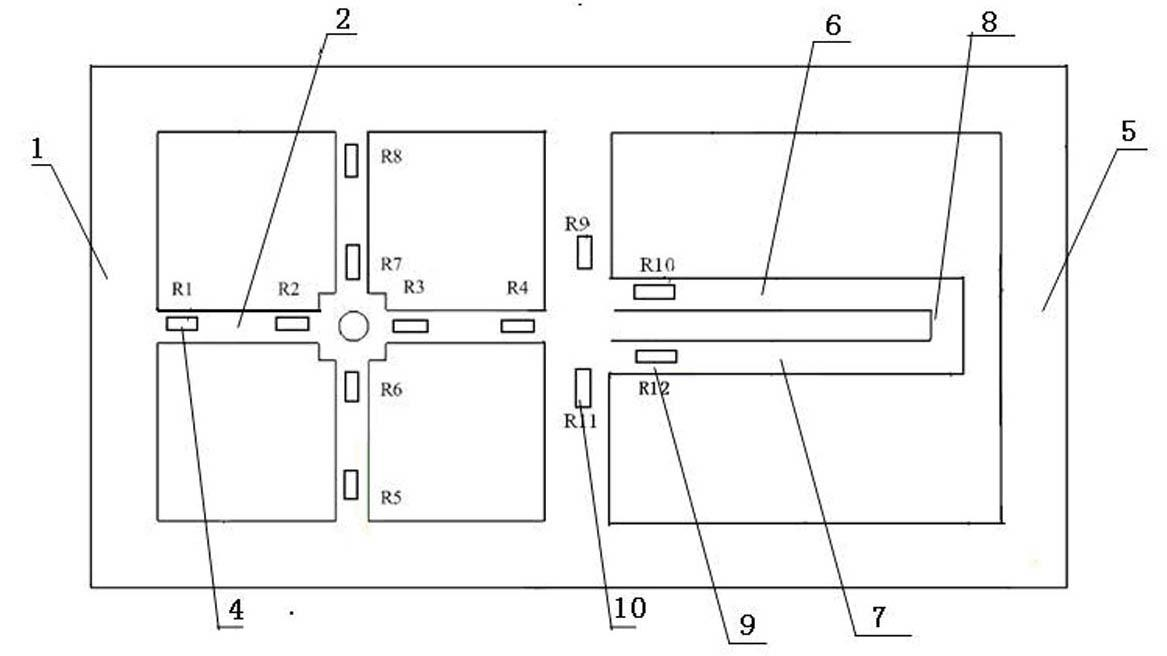

[0049] Such as figure 2As shown, the three-dimensional vector hydrophone includes sensitive units for sensitive underwater acoustic signals in the three directions of X, Y, and Z, which are processed by MEMS micromachining technology; The sensitive unit of the underwater acoustic signal in two directions is the same sensitive unit, including the semiconductor frame 1, the cross-shaped cantilever beam 2 erected in the center of the semiconductor frame 1, and the micro The columnar body 3, the four-beam ends of the cross-shaped cantilever beam 2 are respectively provided with strain-sensitive elements 4 (for example: piezoresistors, resonant tunneling diodes RTD, etc.), and the strain-sensitive elements 4 at the four-beam ends of the cross-shaped cantilever beam 2 Connect to form two full-bridge differential circuits for measuring underwater acoustic signals in X and Y directions respectively, such as Figure 4 , 5 As shown; the sensitive unit for sensitive Z-direction underw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com