Method and system for detecting material defects based on photonuclear reaction

A technology for detecting materials and defects, applied in the direction of material analysis using measurement of secondary emissions, and can solve problems such as inability to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

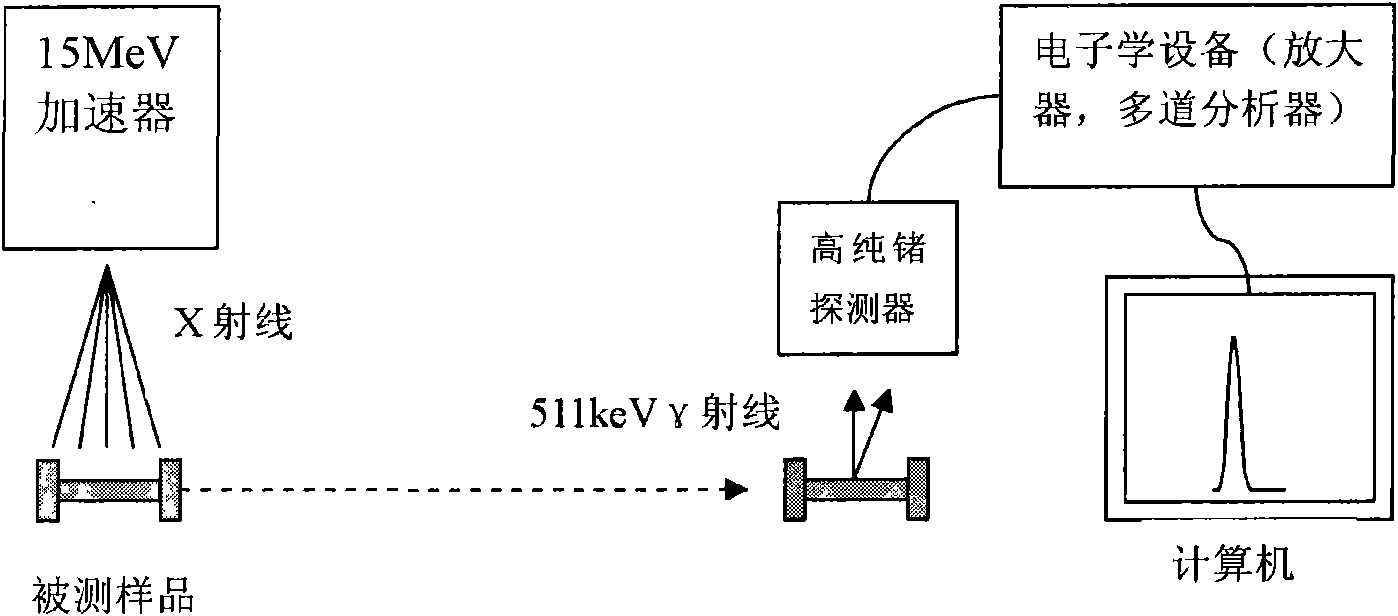

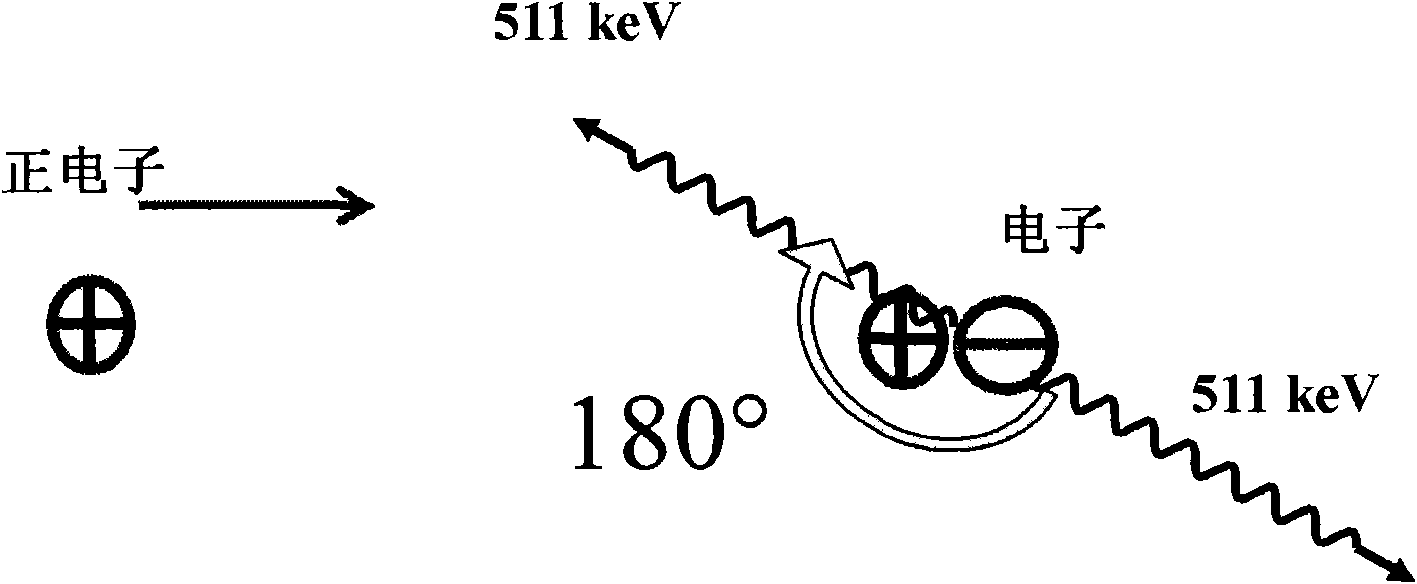

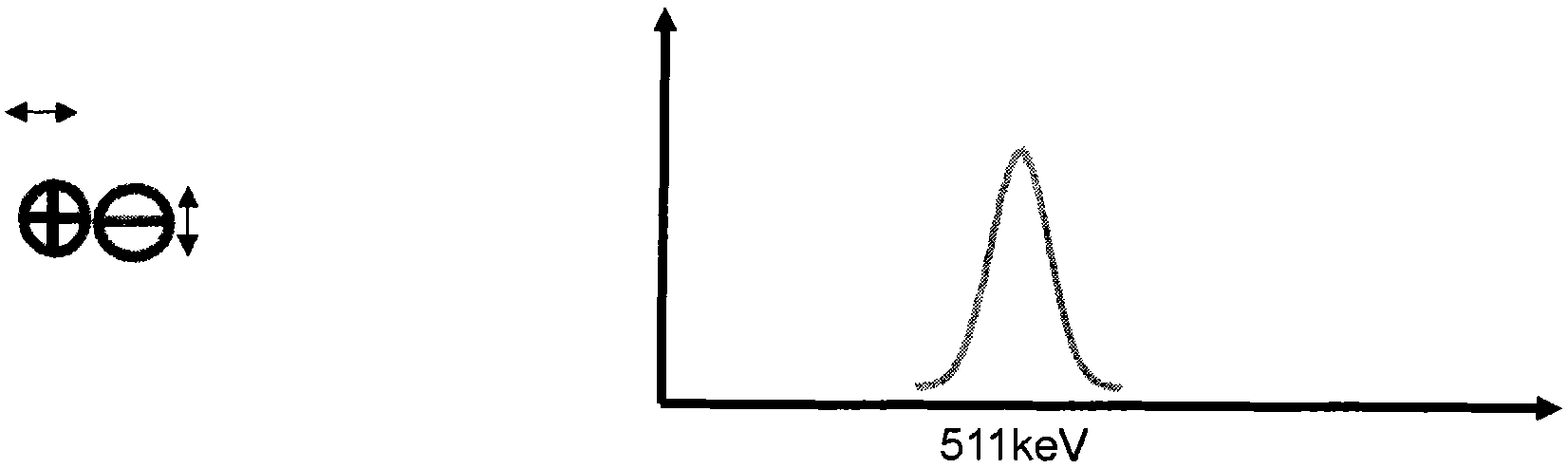

[0016] figure 1 It is a schematic diagram of the system for detecting material defects based on photonuclear reaction of the present invention. As shown in the figure, the high-energy X-rays generated by the 15MeV electron accelerator scan the sample under test. Because X-rays have strong penetrating power in the material, they can penetrate deep into the sample, instead of ordinary positrons, which can only analyze the surface layer. After X-ray penetrates into the material, it can interact with some parts of the sample. A photoneutron reaction occurs in the nucleus, causing the nucleus to lose a neutron. After the neutron is lost, the nucleus becomes a neutron-deficient nucleus, so it has β+ radioactivity and can emit positrons, so that positrons are generated inside the sample.

[0017] In the photopositron analysis technology of the present invention, the radiation source used is X-rays generated by a high-energy electron accelerator. The energy of the accelerator is require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com