Method and equipment for recycling metal and insulating covers in waste cables

A technology of insulating sheath and waste cables, applied in recycling technology, electronic waste recycling, electrical components, etc., can solve the problems of cable crushing and recycling, tool wear copper loss, energy consumption increase, etc., to improve recovery rate, Effect of reducing copper loss and cutting tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

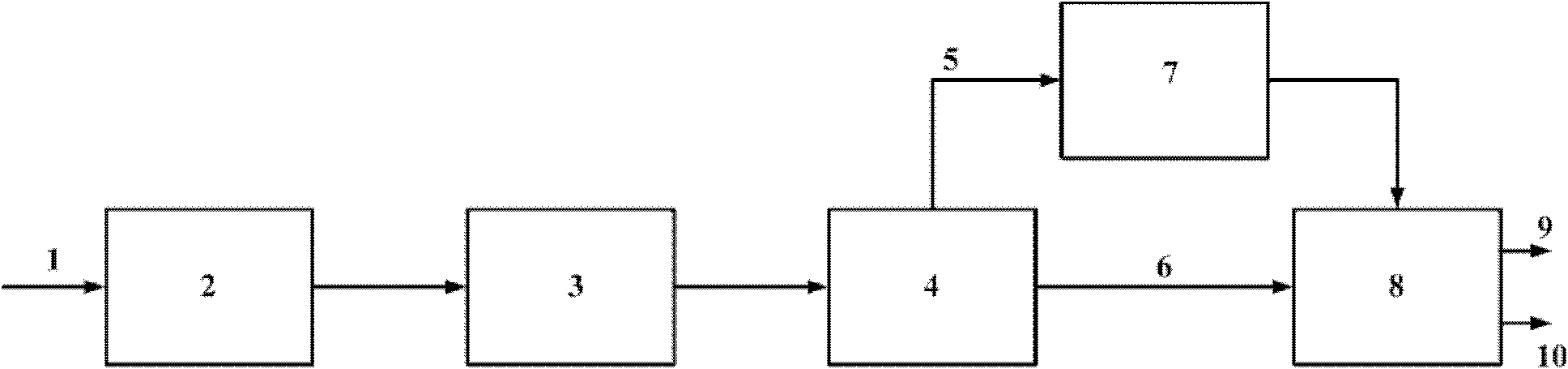

[0032] See Figure 1 ~ Figure 3 , a method for reclaiming metal and insulating sheaths in waste cables, comprising the following steps:

[0033] 1) Straighten out the messy waste cables manually.

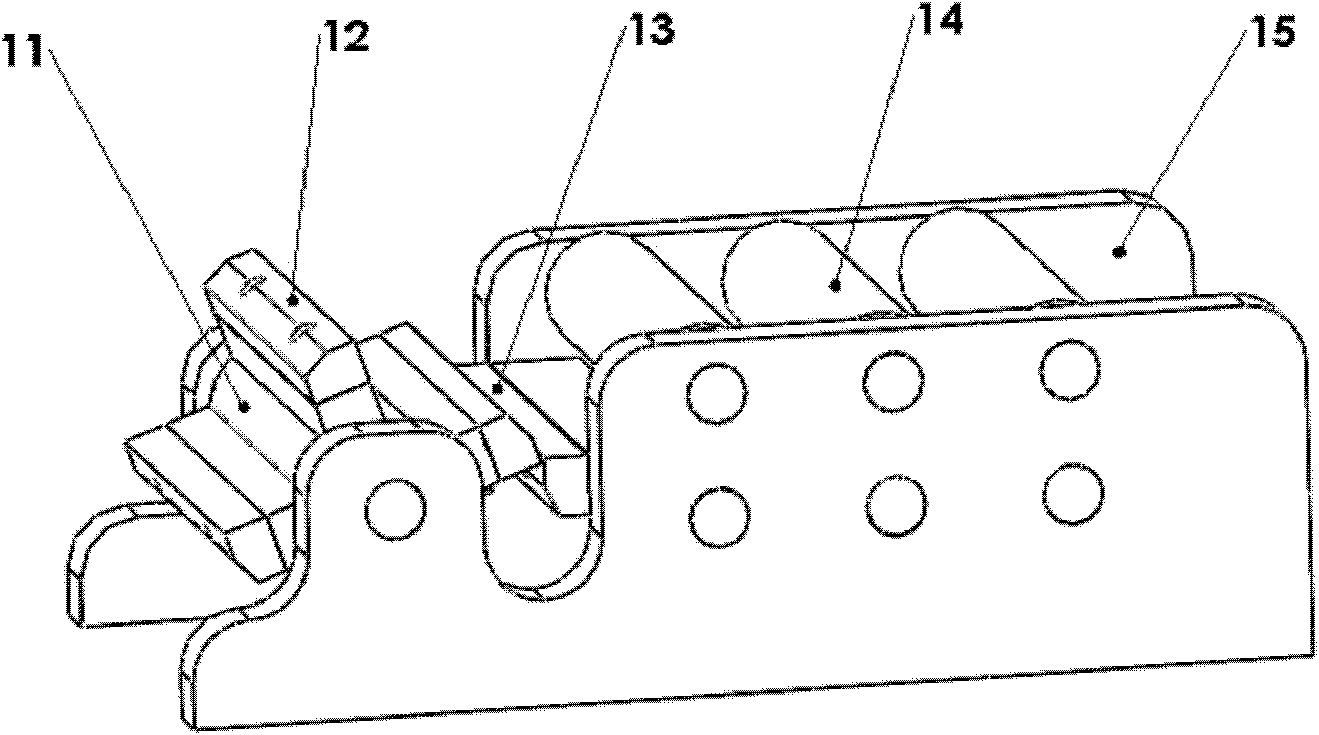

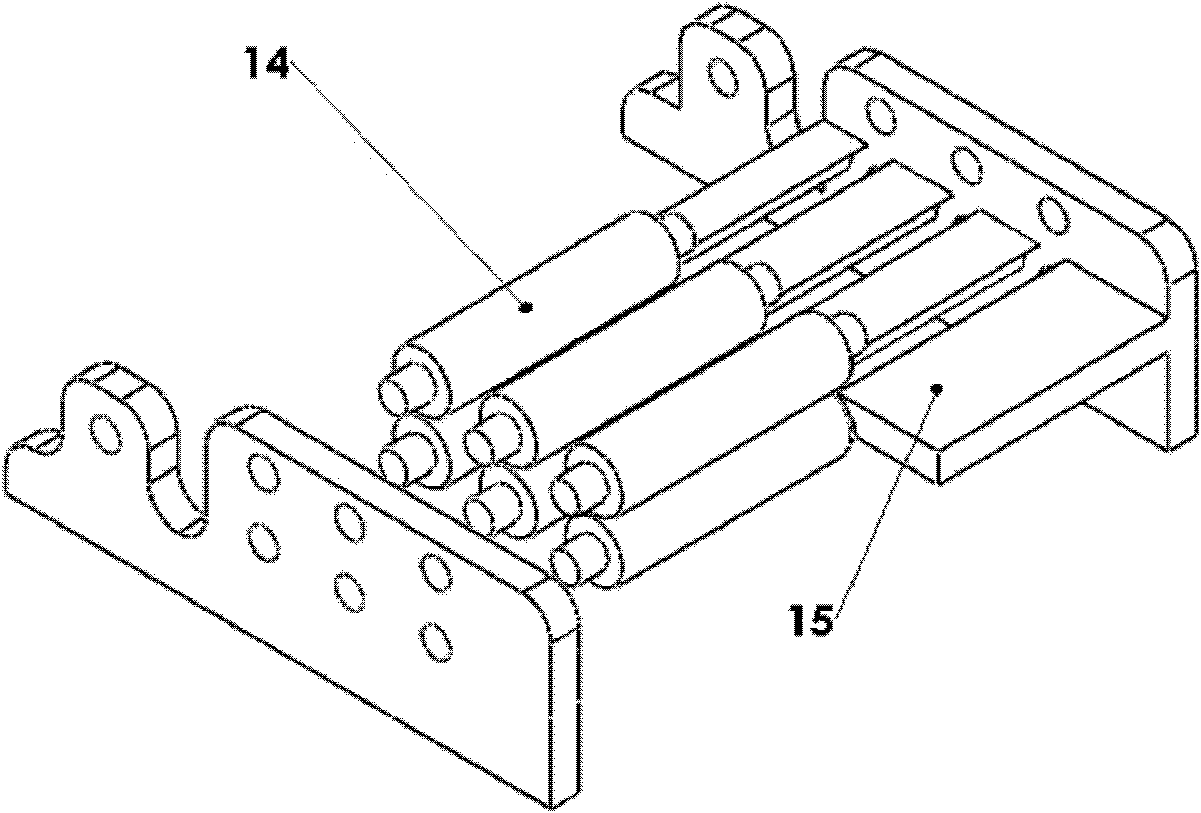

[0034] 2) Send the straightened cable 1 into the rolling device 2, and the rolling device 2 rolls the straightened cable 1, and sends the flattened cable to the rotary cutting device 3, and cuts the cable Be the short section cable of 2-4mm length; Rolling device 2 can adopt such as figure 2 The structure shown in includes one or more pairs of rollers 14. The rollers 14 are supported on the frame 15 and driven by a motor. The rotational speeds of the rotating shafts 11 are matched. Rotary cutting device 3 can adopt as figure 2 The structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com