Soft start method of efficient self-starting permanent magnet synchronous motor

A permanent magnet synchronous and self-starting technology, which is applied to synchronous machines, electrical components, electromechanical devices, etc., can solve the problem of hindering the starting and acceleration of high-efficiency self-starting permanent magnet synchronous motors, and reduce the electromagnetic torque of high-efficiency self-starting permanent magnet synchronous motors , It is not conducive to the starting of high-efficiency self-starting permanent magnet synchronous motors, etc., to achieve the effect of small mechanical vibration, large starting torque and small starting current

Inactive Publication Date: 2011-06-29

FUZHOU INSTITUE OF TECH +1

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

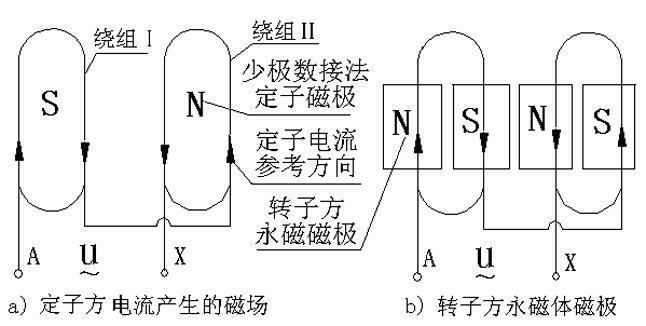

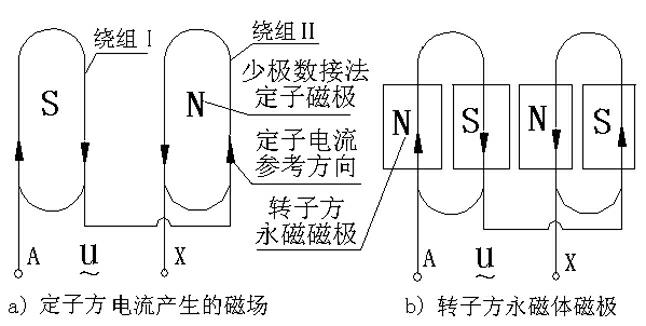

Figure 1 is a schematic structural diagram of a known high-efficiency self-starting permanent magnet synchronous motor. The air-gap magnetic field of the high-efficiency self-starting permanent magnet synchronous motor shown in the figure is provided by the rotor side permanent magnet, and no power supply is required to provide excitation current, which has high efficiency and However, during the starting process of the high-efficiency self-starting permanent magnet synchronous motor, due to the mutual cutting between the magnetic field of the rotor permanent magnet and the stator winding, an induced current is generated in the stator winding, and the induced current increases the high-efficiency self-starting permanent magnet synchronous motor. At the same time as the starting current of the magnetic synchronous motor, the induction current interacts with the magnetic field of the permanent magnet to generate the braking torque of the asynchronous permanent magnet generator. The electromagnetic torque during the starting process hinders the starting and acceleration of the high-efficiency self-starting permanent magnet synchronous motor, and the harmonic component of the permanent magnet magnetic field also produces the braking torque of the asynchronous permanent magnet generator with harmonic components, causing high-efficiency self-starting permanent magnet synchronous The motor produces mechanical oscillation during the starting process, which has an adverse effect on mechanical equipment. Therefore, the braking torque of the asynchronous permanent magnet generator is not conducive to the starting of the high-efficiency self-starting permanent magnet synchronous motor, and is the main factor affecting the starting performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

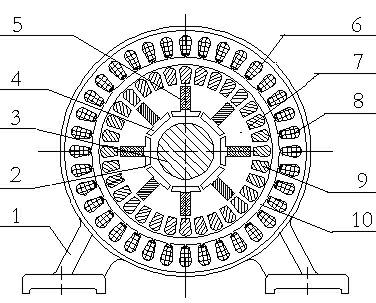

The invention relates to a soft start method of an efficient self-starting permanent magnet synchronous motor, which is characterized in that the rotor of the efficient self-starting permanent magnet synchronous motor is provided with a squirrel cage winding used for asynchronous self-starting and a permanent magnet pole; the stator of the efficient self-starting permanent magnet synchronous motor is provided with a set of pole-changing simplex windings with bipolar numbers; the permanent magnet pole numbers of the rotor are equal to twice of pole numbers of less connecting windings of the pole-changing windings; the pole numbers of multipolar connecting windings are equal to the permanent magnet pole numbers of the rotor, so that the permanent magnet synchronous motor can realize asynchronous self-starting in an asynchronous motor state and operates at a synchronous speed in a state approximate to the synchronous speed state, the soft self-starting of the efficient self-starting permanent magnet synchronous motor is realized, the efficient self-starting permanent magnet synchronous motor has the characteristics of large starting torque, small starting current, small mechanical vibration and the like, and the starting performance of the efficient self-starting permanent magnet synchronous motor is improved.

Description

Soft starting method for high-efficiency self-starting permanent magnet synchronous motor technical field The invention relates to the technical field of permanent magnet motors, in particular to a soft starting method for high-efficiency self-starting permanent magnet synchronous motors. Background technique The air-gap magnetic field of the permanent magnet synchronous motor is provided by the permanent magnet. The rotor does not produce copper loss in the synchronous speed operation state. The efficiency and high power factor of the permanent magnet synchronous motor are much higher than that of the asynchronous motor. It is a typical high-efficiency and energy-saving product. Figure 1 is a schematic structural diagram of a known high-efficiency self-starting permanent magnet synchronous motor. The air-gap magnetic field of the high-efficiency self-starting permanent magnet synchronous motor shown in the figure is provided by the rotor side permanent magnet, and no power...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02K21/46

Inventor 吴亚麟吴晗青吴冬锴

Owner FUZHOU INSTITUE OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com