Connecting structure and connecting method for PCB

A PCB board and connection structure technology, which is applied in the direction of electrical connection of printed components, printed circuit components, and assembly of printed circuits with electrical components, can solve the problems of increased device cost, poor reliability, and occupancy, and achieve PCB board area reduction , increase flexibility and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will now be described with reference to the accompanying drawings, in which like reference numerals represent like elements.

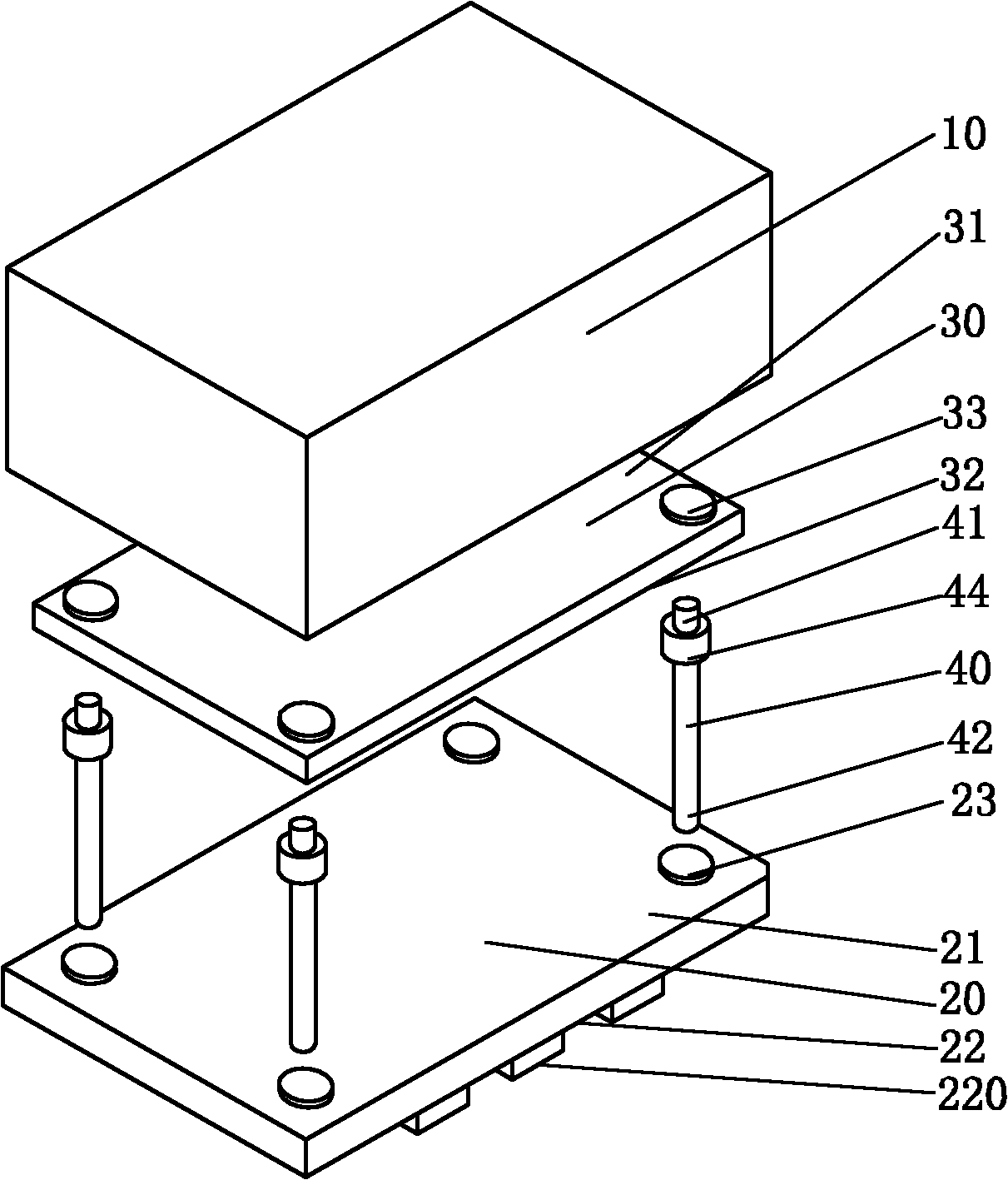

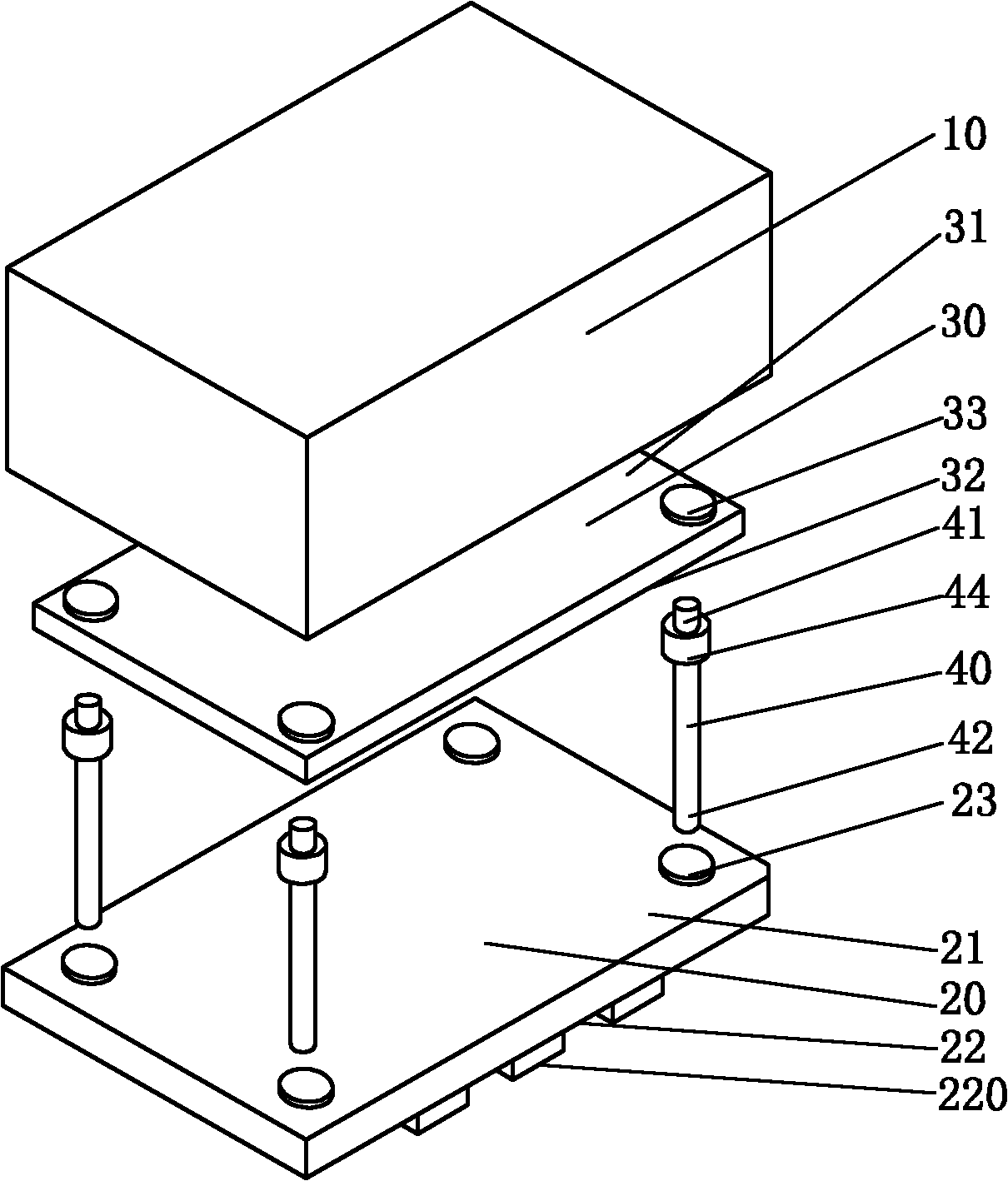

[0022] First please refer to figure 1 , The connection structure of the PCB board of the present invention includes a metal casing 10 , a PCB motherboard 20 , a PCB daughter board 30 and a plurality of connection pins 40 . The upper surface 21 of the PCB motherboard 20 is the component welding surface, the lower surface 22 of the PCB motherboard 20 forms the device pads 220, and the device pads 220 are the function lead-out pads of the device. The lower surface 22 of the board 20 is made of a copper clad layer and is used for soldering on the PCB board of the application product; and the PCB motherboard 20 is provided with a number of buried holes 23 through the upper surface 21 and the lower surface 22 . The upper surface 31 and the lower surface 32 of the PCB sub-board 30 are both component welding surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com