Cocoa butter replacer composite as well as preparation method and application thereof

A technology of cocoa butter substitute and composition, which is applied in the field of cocoa butter substitute composition for chocolate coating and its preparation, which can solve problems such as poor taste, poor heat resistance of CBR, cracking of chocolate coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] CBR1

[0050] Shea butter (iodine value 50-60gI / 100g), acetone fractionation obtains shea butter liquid oil (iodine value 60-70gI / 100g), then with 9908 as catalyst (addition 0.1% (by weight of oil) )) for hydrogenation, the reaction temperature is 150-200°C, the pressure is 1-5bar, the iodine value is reduced to 45-56gI / 100g, and then refined, and lecithin is added to obtain CBR 1. The results are shown in Table 1 and Table 2.

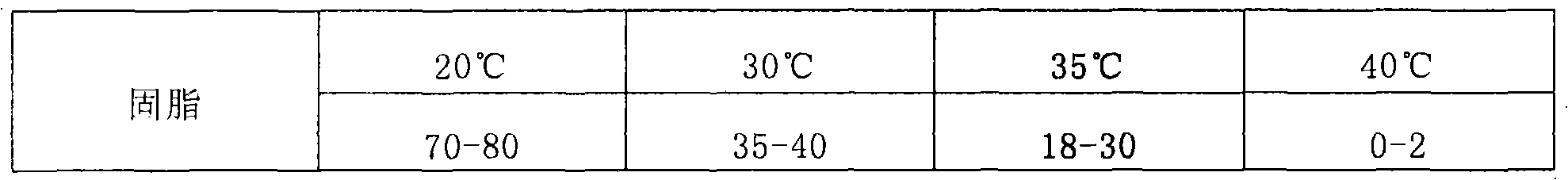

[0051] Table 1

[0052]

[0053] Table 2

[0054]

Embodiment 2

[0056] CBR2

[0057] Shea butter (iodine value 55-60gI / 100g), petroleum ether fractionation obtains shea butter liquid oil (iodine value 60-70gI / 100g), then with 9908 (addition amount 0.08%) and 9920 (addition amount 0.02%) % (based on the weight of oil) is used as a catalyst for hydrogenation, the reaction temperature is 150-200 ° C, the pressure is 1-5 bar, the iodine value is reduced to 45-56 gI / 100 g, and then refined, adding PGPR 0.2% (to obtain CBR The total weight basis), to obtain CBR 2. The results are shown in Table 3.

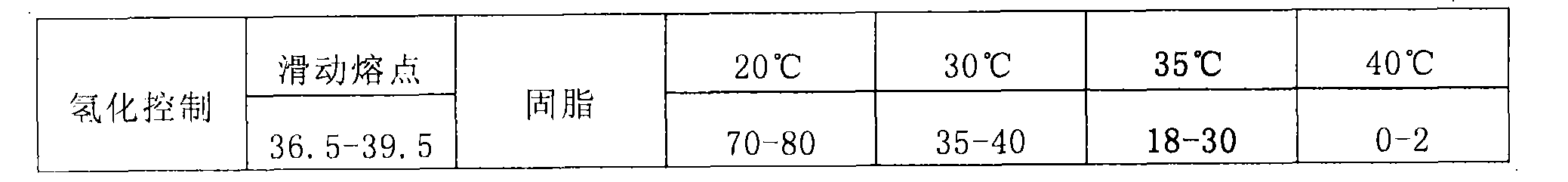

[0058] table 3

[0059]

Embodiment 3

[0061] CBR3

[0062] Shea butter can obtain shea butter liquid oil (iodine value 60-70gI / 100g) through dry fractionation, carry out 9908 hydrogenation or 9920+9908 mixed hydrogenation (with the condition of embodiment 1), then carry out refining, The results are shown in Table 4.

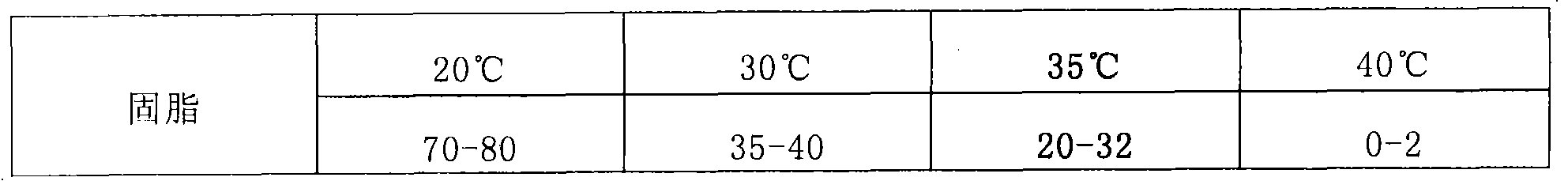

[0063] Table 4

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com