Device for separating pollutant in garbage leachate

A technology of landfill leachate and gas-liquid separation device, which is applied in the direction of water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of high process cost, unreachable, and polluted environment and other problems to achieve the effect of small size and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

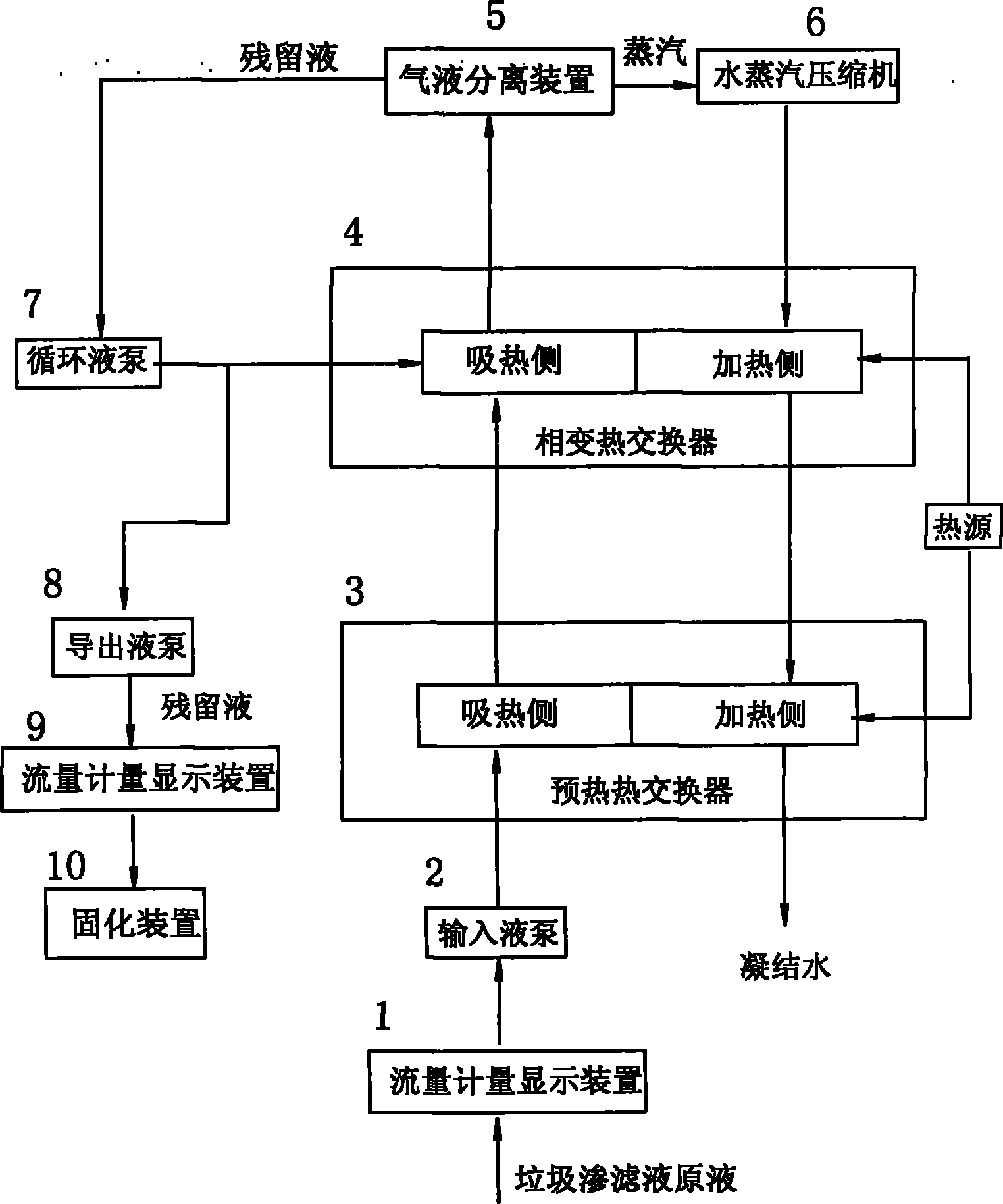

[0028] This example is a device system connected by pipelines for the separation of pollutants in landfill leachate. The structure of the system is:

[0029] There is an input liquid pump 2 with a flow quantitative and adjustment control device, its input channel is connected with a flow measurement display device 1, and its output end is connected with the input end of the heat absorption channel of the preheating heat exchange device 3;

[0030] The preheating heat exchange device 3 is a plate evaporator, and the heat-absorbing channel and the heat-releasing channel are separated by a heat transfer wall;

[0031] The output end of the heat absorption channel of the preheating heat exchange device 3 is connected to the input end of the heat absorption channel of the phase change heat exchange device 4;

[0032] The phase-change heat exchange device 4 is a plate evaporator, which separates the heat-absorbing channel from the heat-releasing channel through a heat transfer wall,...

Embodiment 2

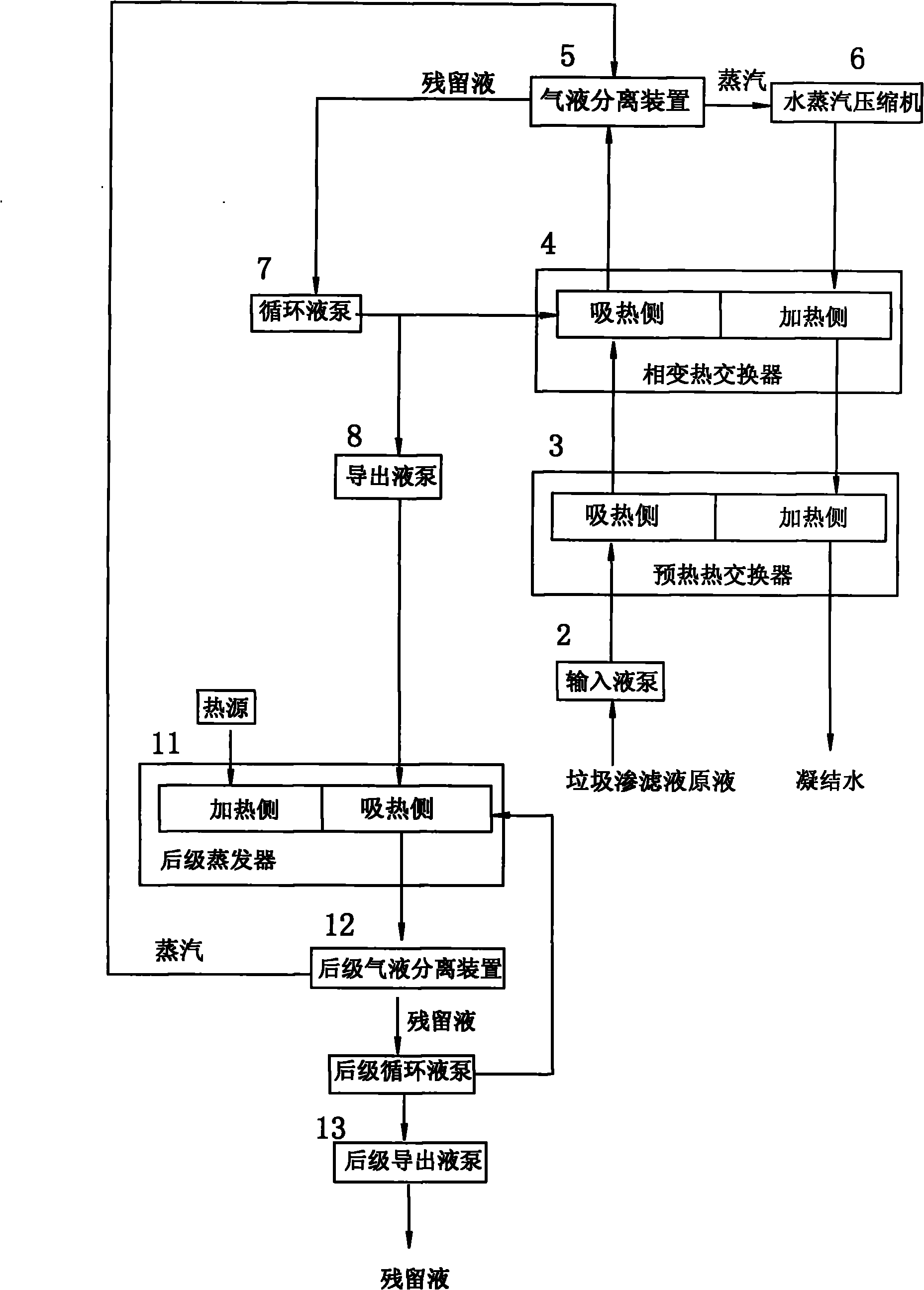

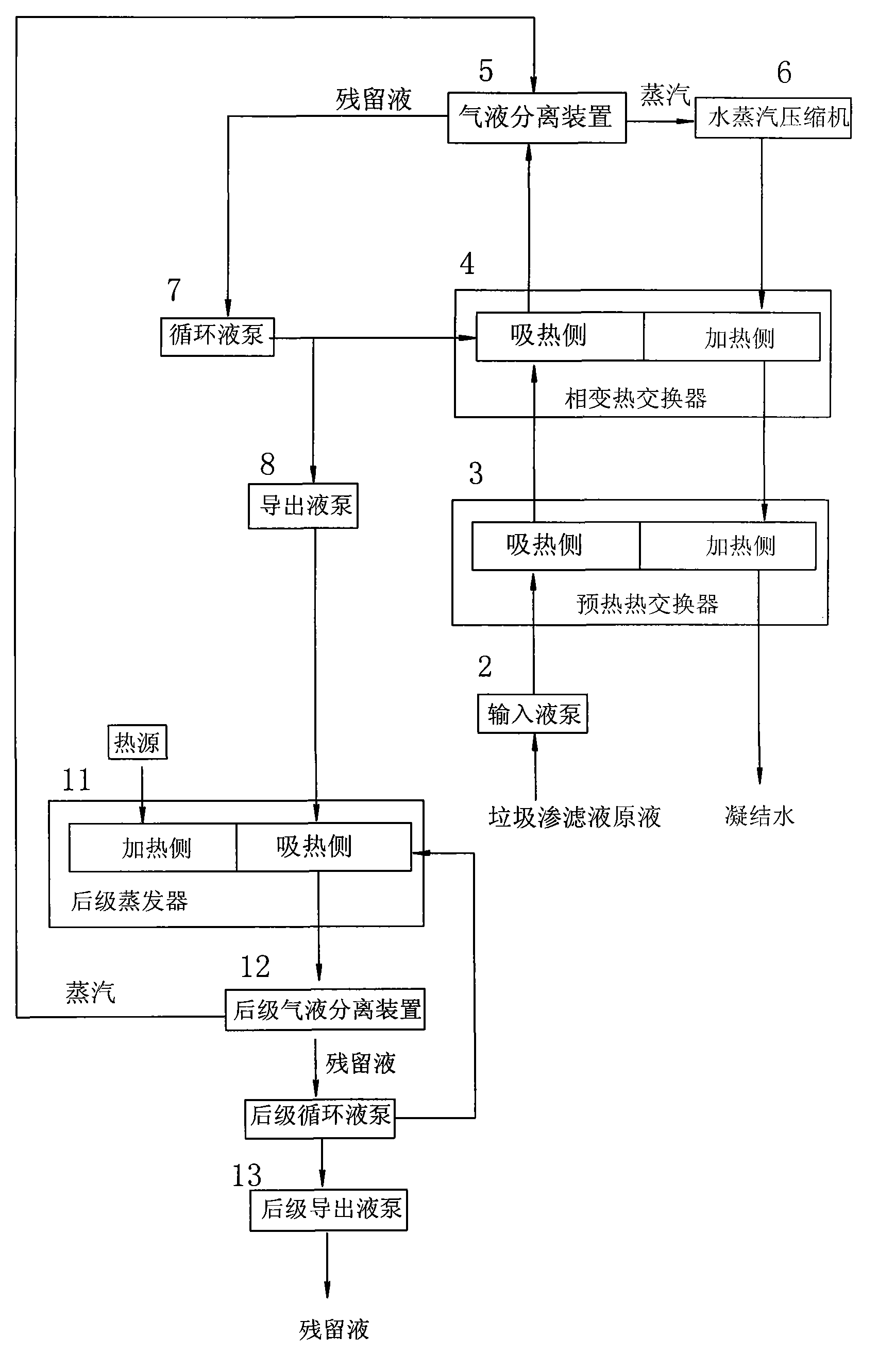

[0039] The difference with embodiment 1 is:

[0040] In this example, a first-stage post-stage evaporator 11 (multi-stage can also be set) is set at the rear of the outlet liquid pump 8, specifically:

[0041] The output end of the export liquid pump 8 is connected to the heat absorption channel of the rear-stage evaporator 11, the output end of the heat absorption channel is connected to the input end of the subsequent gas-liquid separation device 12, and the steam output end of the rear-stage gas-liquid separation device is connected to the upstream steam channel The liquid output end of the second-stage gas-liquid separation device is connected to the residual liquid output end through the second-stage export liquid pump 13, and the heating side of the latter-stage evaporator 11 is provided with a heat source.

[0042] The upstream water vapor passage may be the phase change heat exchange device 4, or the gas-liquid separation device 5, or the water vapor compressor 6, or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com