Preparation method of core shell type nanowire

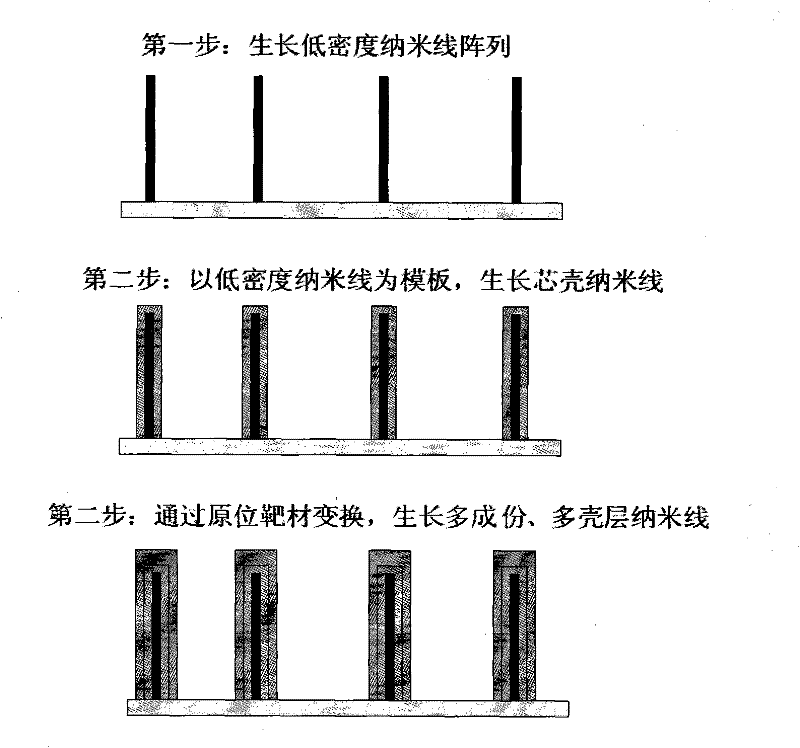

A technology of nanowires and nanowire arrays is applied in the field of laser deposition preparation of core-shell nanowires and the growth of zinc oxide-based nanowire heterojunctions, which can solve the problem of expensive metal-organic vapor deposition equipment and affecting nanowire heterojunctions. Uniformity, irregularity of zinc oxide nanowires, etc., to achieve the effect of convenient shell thickness control, uniform heterojunction, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

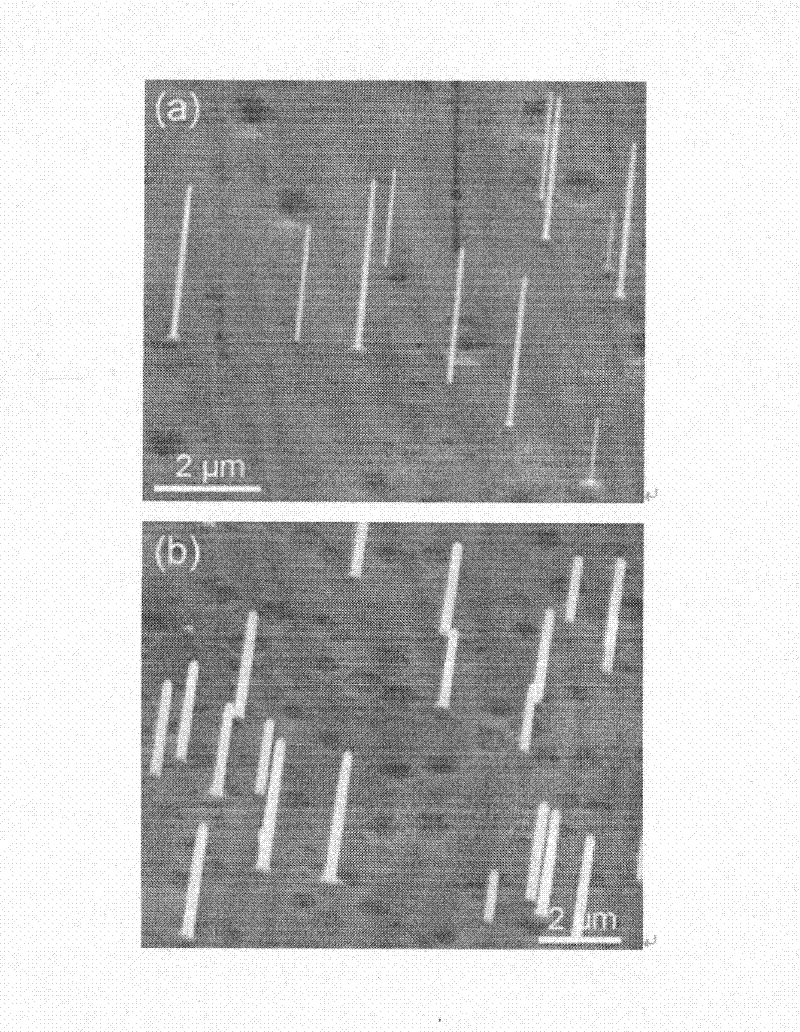

[0021] (ZnO / Zn 0.9 Mg 0.1 Preparation of O core-shell nanowires)

[0022] (1) Using zinc oxide powder with a purity of 99.999% as a raw material, the target material of zinc oxide is made through tableting and sintering processes.

[0023] (2) Zinc oxide thin film material is grown by traditional low-pressure pulse deposition process. The specific growth parameters are as follows: the target is a zinc oxide target as described in (1) preparation method, the growth temperature is 650°C, and the growth pressure is 10 -4 mbar, the background pressure is high-purity oxygen, and the substrate is sapphire (Al 2 o 3 ), size 1×1cm 2 , the laser working conditions are: wavelength 248nm, frequency 10Hz, energy density 1-2J / cm 2 , the growth time is 10 minutes.

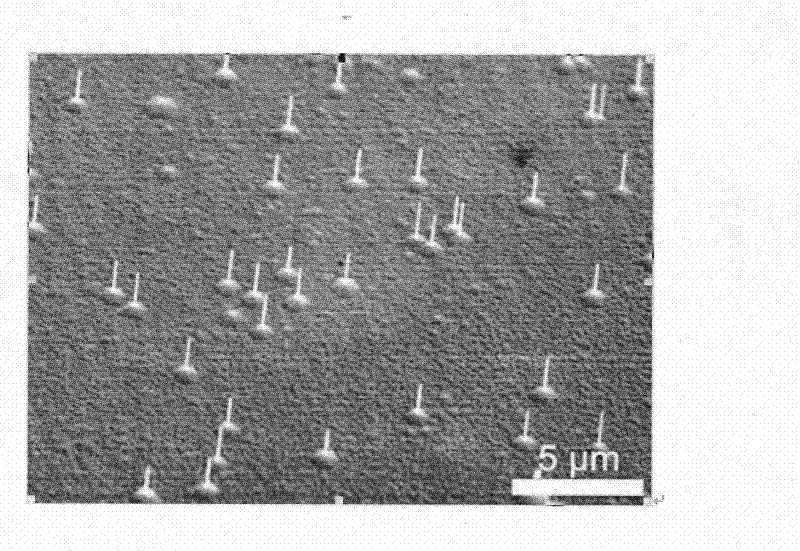

[0024] (3) A low-density zinc oxide nanowire array is grown by a high-voltage pulsed laser ablation method. The specific growth parameters are as follows: the growth temperature is 850 ° C, the growth pressure is 100 mba...

Embodiment 2

[0026] Embodiment 2 (ZnO / (Zn 0.9 Mg 0.1 O / ZnO / Zn 0.9 Mg 0.1 O) Preparation of core-multi-shell (quantum well) nanowires)

[0027] (1-4) step with embodiment 1, prepare ZnO / Zn 0.9 Mg 0.1 O core-shell nanowire array samples.

[0028] (5) with ZnO / Zn 0.9 Mg 0.1 O core-shell nanowires are used as templates, and the target material is replaced with zinc oxide (ZnO) in situ, and the zinc oxide shell layer is epitaxially grown under the following low-voltage pulse deposition process conditions: the growth temperature is 650 ° C, and the growth pressure is 10 -4 mbar, the background pressure is high-purity oxygen, the working conditions of the laser are: wavelength 248nm, frequency 1Hz, energy density 1-2J / cm 2 . And strictly control the growth thickness of the zinc oxide shell through the growth time, so as to grow ZnO / Zn 0.9 Mg 0.1 O / ZnO core-shell nanowires.

[0029] (6) with ZnO / Zn 0.9 Mg 0.1 O / ZnO core-shell nanowires are used as templates, and the target is replace...

Embodiment 3

[0030] Embodiment 3 (growth of different composition multi-shell nanowires)

[0031] (1-6) synchronous example 2, as connotation and extension of the present invention, its shell composition can be following multiple and is suitable for laser pulse deposition material: Zn x Mg 1-x O(0≤x≤0.3); Al 2 o 3 ; MgO; MnO; ZnO: X (X: N; P; As, etc.); under the technical process conditions described in the present invention, the number of shell layers can be 1-15. As the above-mentioned processes included in the present invention, they are not listed one by one in this specification, but are also included in the present invention.

[0032] In summary of the above implementation examples, the process of the present invention can realize the growth of a class of core-shell nanowires with a uniform structure. Core-shell semiconductor nanowires are of vital scientific and practical significance for the assembly of semiconductor heterostructures of ZnO nanowires, light-emitting diode devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap