High-barrier non-woven fabric composite material, and manufacturing method and special equipment thereof

A technology of composite materials and non-woven fabrics, which is applied in the direction of textiles, papermaking, and non-woven fabrics. It can solve the problems of complex procedures, time-consuming and labor-intensive, high production costs, and achieve cost savings, improved barrier capacity, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

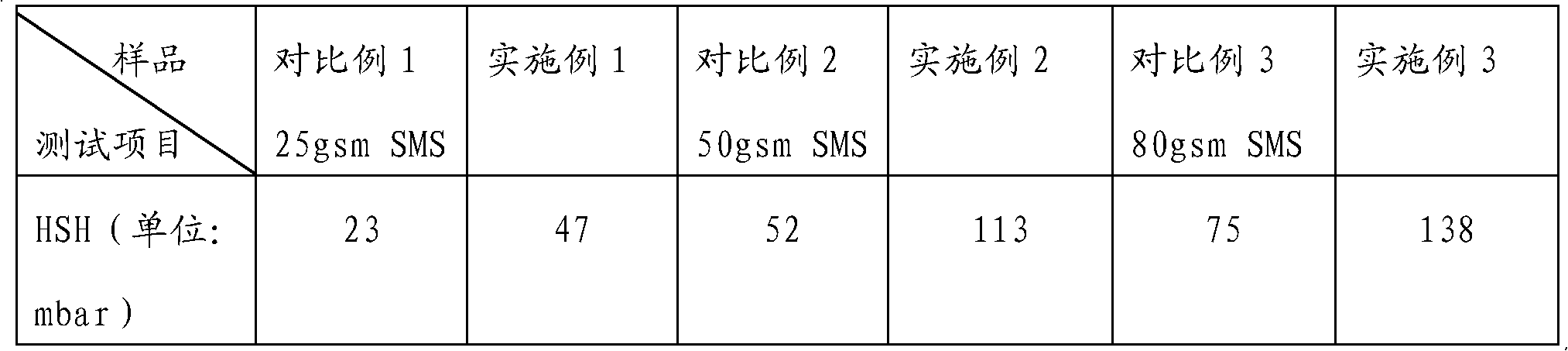

[0020] A high-barrier non-woven composite material, comprising at least two layers of spun-bonded non-woven fabrics and at least one layer of microfiber film-like structural material integrally formed; Between non-woven fabrics, each layer of spun-bonded non-woven fabric is 10g / m 2 , the microfiber membrane structure material is 5g / m 2 .

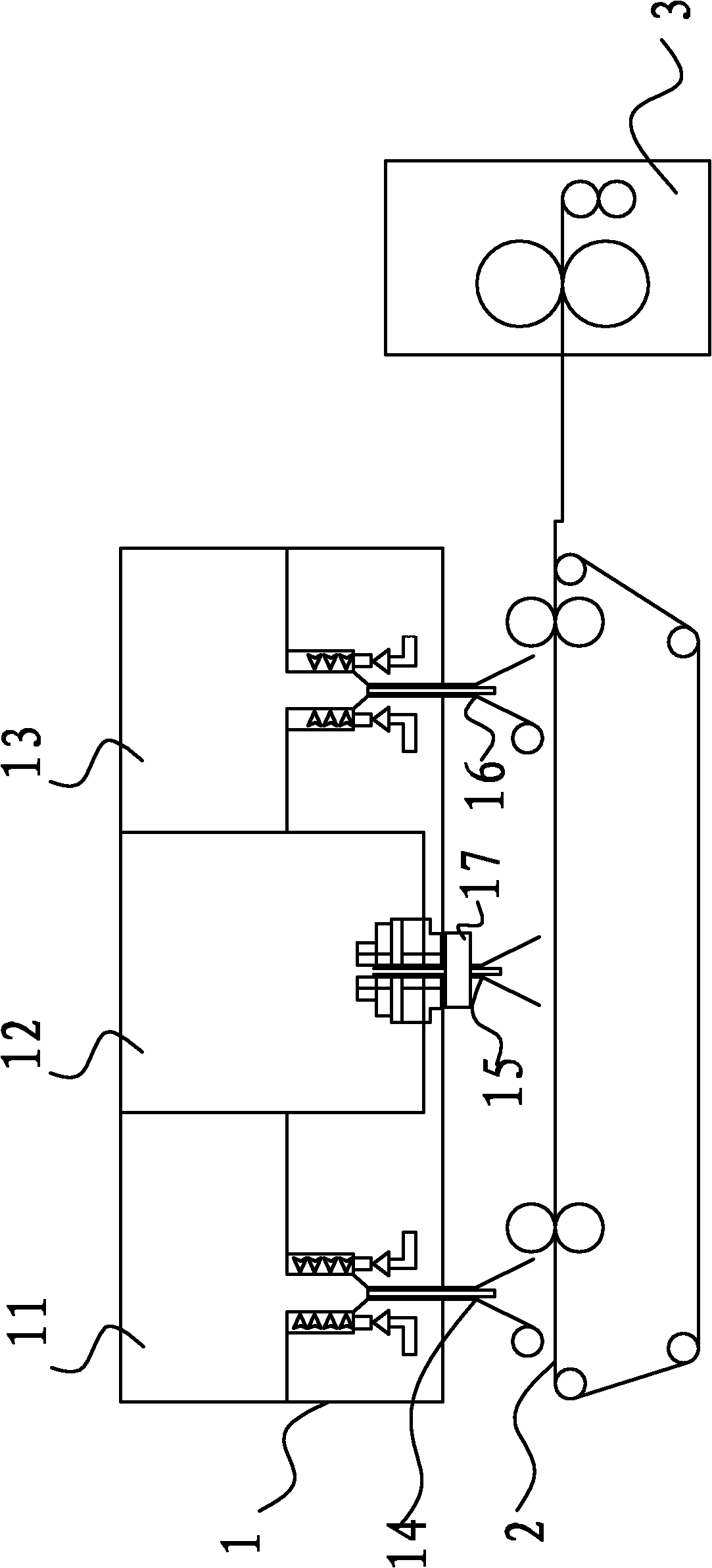

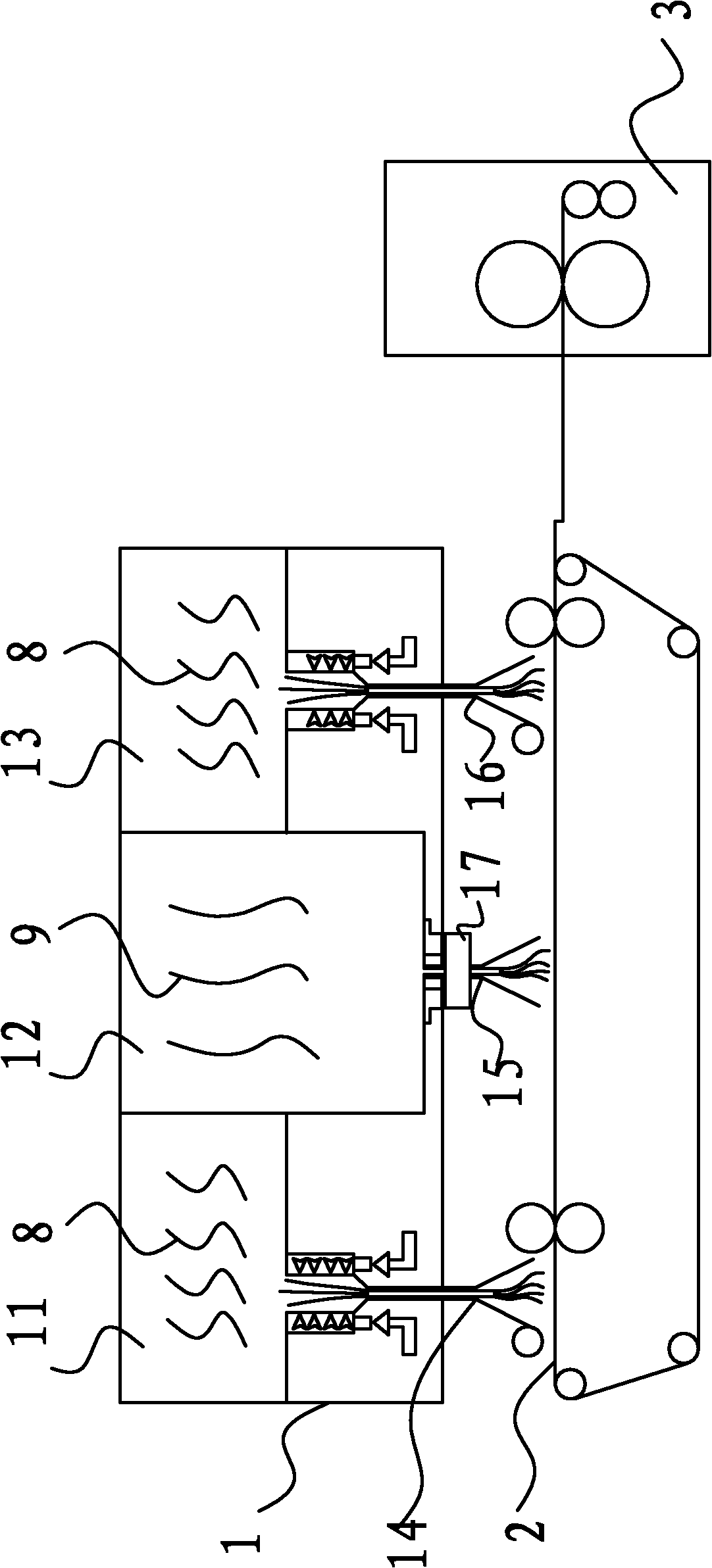

[0021] The equipment for preparing said high-barrier non-woven fabric, see figure 2 Including a workbench 2, a feeder 1 and a hot rolling mill 3, the feeder is provided with at least two completely isolated accommodation spaces for spunbond non-woven materials, the first accommodation space 11 for spunbond non-woven materials A first spun-bonded non-woven fabric material outlet 14 is provided near the end of the workbench, and a second spun-bonded non-woven fabric material outlet 16 is provided near the end of the workbench in the accommodation space 13 of the second spun-bonded non-woven fabric material; At least one melt-blown cloth ma...

Embodiment 2

[0029] A high-barrier non-woven fabric, comprising at least two layers of spunbond nonwoven fabric and at least one layer of ultrafine fiber film structure material integrally formed; the ultrafine fiber film structure material is sandwiched between the spunbond nonwoven fabric Between cloths, each layer of spunbonded non-woven fabric is 17.5g / m 2 , the microfiber membrane structure material is 15g / m 2 .

[0030] The equipment for preparing the high-barrier non-woven fabric is the same as that of Example 1; the difference is that the step C, opening the equipment, and opening the calender 17, the surfaces of the two rollers in the calender 17 are smooth, It is two metal rollers; the melt-blown cloth material 9 is hot-pressed under the process conditions of 110°C and 50N / mm to obtain a superfine fiber film-like structural material 91;

[0031] The method for preparing a high-barrier non-woven fabric with the above-mentioned equipment is the same as that of Example 1, except t...

Embodiment 3

[0033] A high-barrier non-woven fabric, comprising at least two layers of spunbond nonwoven fabric and at least one layer of ultrafine fiber film structure material integrally formed; the ultrafine fiber film structure material is sandwiched between the spunbond nonwoven fabric Between cloths, each layer of spunbonded non-woven fabric is 28g / m 2 , the microfiber membrane structure material is 24g / m 2 .

[0034] The equipment for preparing the high-barrier nonwoven fabric is the same as in Example 1; the difference is that the step C, opening the equipment, and opening the calender 17, the surfaces of the two rollers in the calender 17 are smooth, which is a A metal roller and a rubber roller; the melt-blown cloth material 9 is hot-pressed under the process conditions of 115°C and 60N / mm to obtain a superfine fiber membrane structure material 91;

[0035] The method for preparing high-barrier non-woven fabrics with the above-mentioned equipment is the same as in Example 1, ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com