Masonry construction method for filling wall core pillar, core girder and building blocks into framework structure

A technology of frame structure and construction method, applied in the direction of walls, buildings, building components, etc., can solve the problems of increasing hidden dangers, affecting the overall progress, and reducing time, so as to ensure the quality of decoration, shorten the period of decoration, and improve economic benefits. Effect

Active Publication Date: 2011-07-06

中铁建工集团装饰工程有限公司 +1

View PDF5 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, the problem with the use of lightweight solid blocks is that the lightweight solid blocks have stricter requirements on the setting of ring beam structural columns, and the ring beam structure needs to be added according to the seismic and crack resistance requirements and the length and height of the wall. column

[0003] The shortcomings of adding ring beam structural columns are as follows: 1) In terms of masonry quality, the formwork support and reinforcement of structural column ring beams are most likely to cause cracks or even deformation of the wall, which affects the overall firmness; ring beam structural columns It is also the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

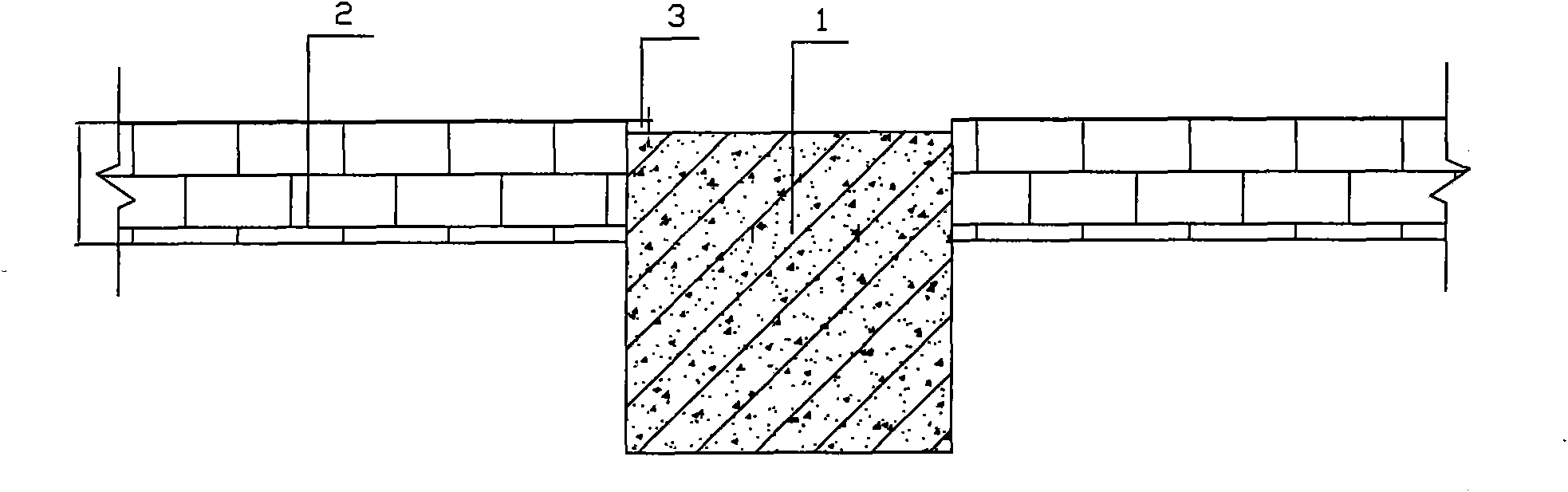

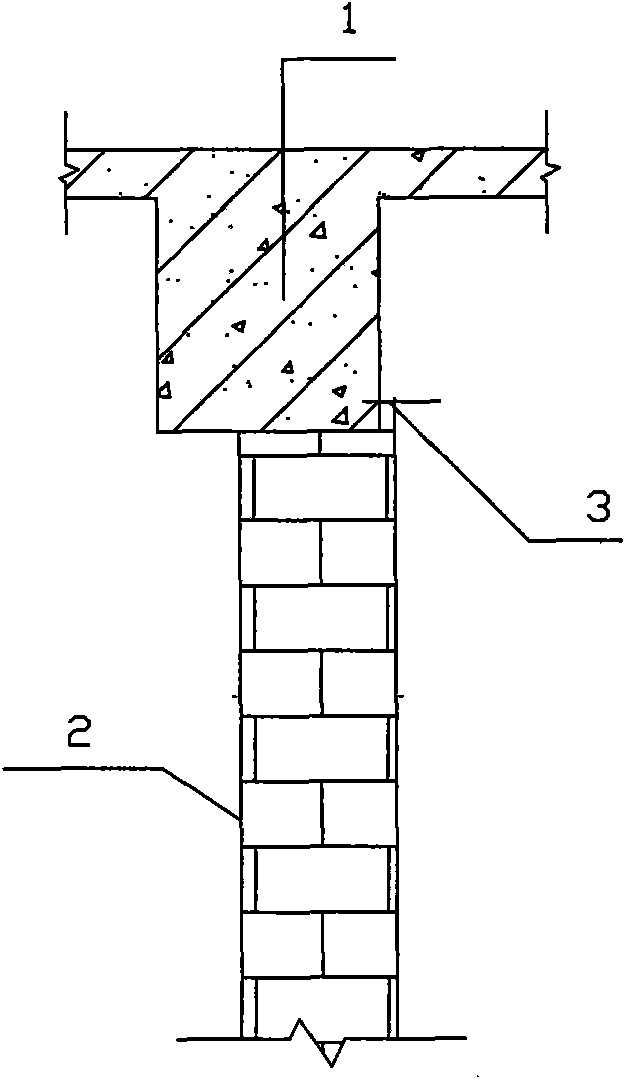

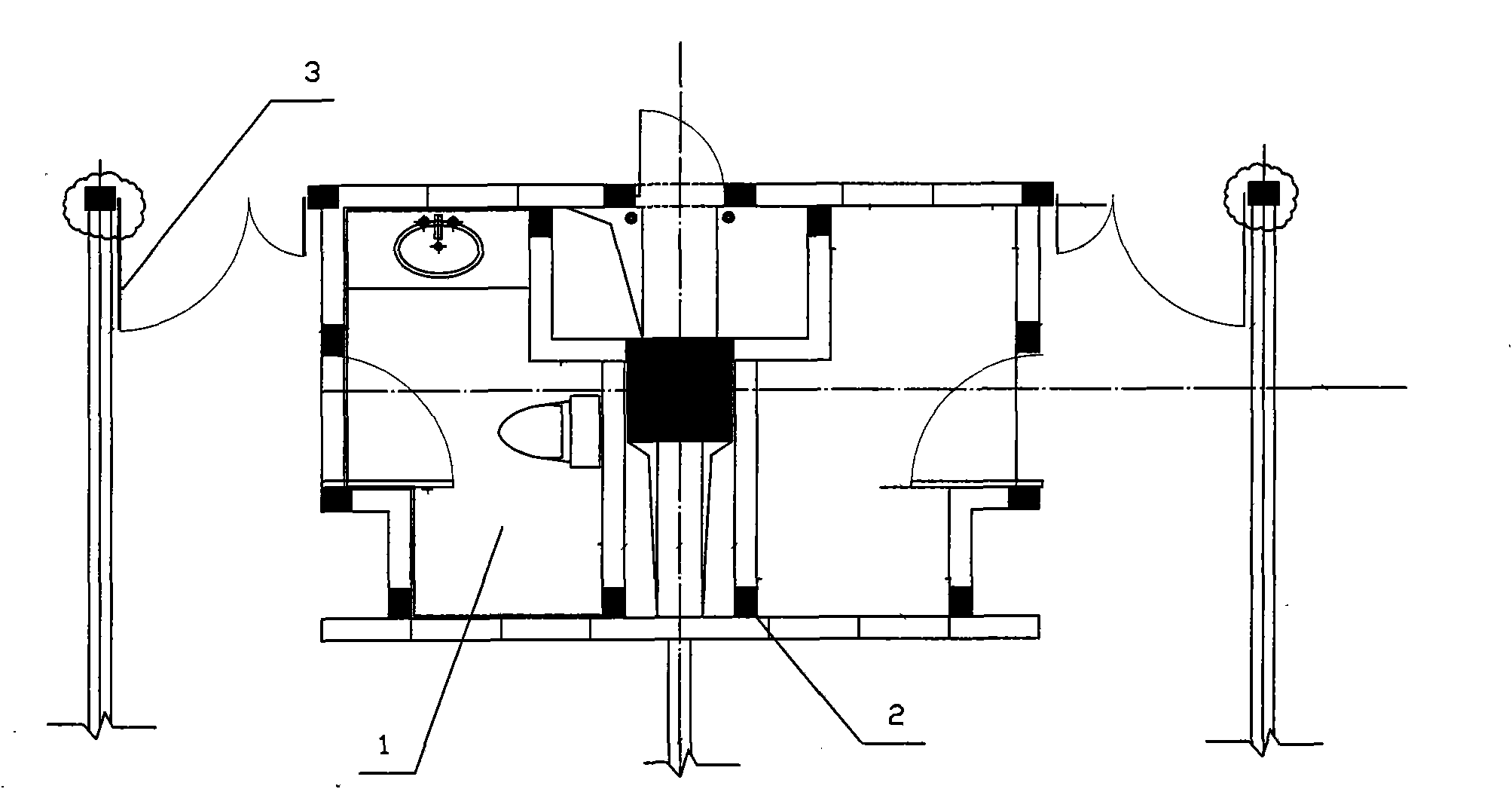

The invention relates to a masonry construction method for filling a wall core pillar, a core girder and building blocks into a framework structure. The method comprises the following steps of: construction preparation, masonry installation, synchronous inspection and puttying according to the condition of the wall surface of brickwork, wherein in the masonry installation step, a construction mode of the core pillar and the core girder is described; the hollow part of a small concrete hollow building block is used for substituting a construction pillar ring and an intel template, so the problems caused by template construction are avoided; during construction, concrete hollow building blocks, light-weight solid building blocks and U-shaped concrete building blocks which meet the national building standard atlas are adopted to build a wall body; according to a preset position, steel bars of the core pillar and the core girder are connected with an original structural layer according toa designed specification and a required quantity of embedded bars; the concrete hollow building blocks are put into the steel bars; and after the mortar of the building body reaches a certain intensity, concrete is poured into holes so as to form a firm whole together with the wall body to achieve a very ideal effect. By the method, a very good economic benefit is achieved, and a wide social favorable comment is obtained.

Description

Technical field: [0001] The invention relates to a wall construction method in house construction. More specifically, it relates to a construction method for filling wall core columns, core beams and blocks in a frame structure. Background technique: [0002] With the development of the economy and the improvement of people's living standards, the requirements for buildings are getting higher and higher, and the contradiction with the increasingly scarce land resources, the small high-rise, high-rise, super high-rise and other frame shear walls of industrial plants There are more and more buildings. From the consideration of energy saving and emission reduction, as well as the purpose of protecting cultivated land, clay bricks are banned or restricted. In addition, lightweight solid blocks have many advantages such as light weight, good sound insulation and heat insulation effects, and good machinability. Filled walls are used more and more. In the prior art, the problem w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B2/56E04B2/64E04C1/00

Inventor 王建营吉明军张志强钱少波朱明浩王坚曹志刚高松田启华周广张丽

Owner 中铁建工集团装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com