Cross-flow fan of composite wire blade impeller

A blade impeller, cross-flow fan technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of not being able to independently take values one by one, and it is difficult to ensure the output and efficiency of the impeller, and achieve the effect of diversity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

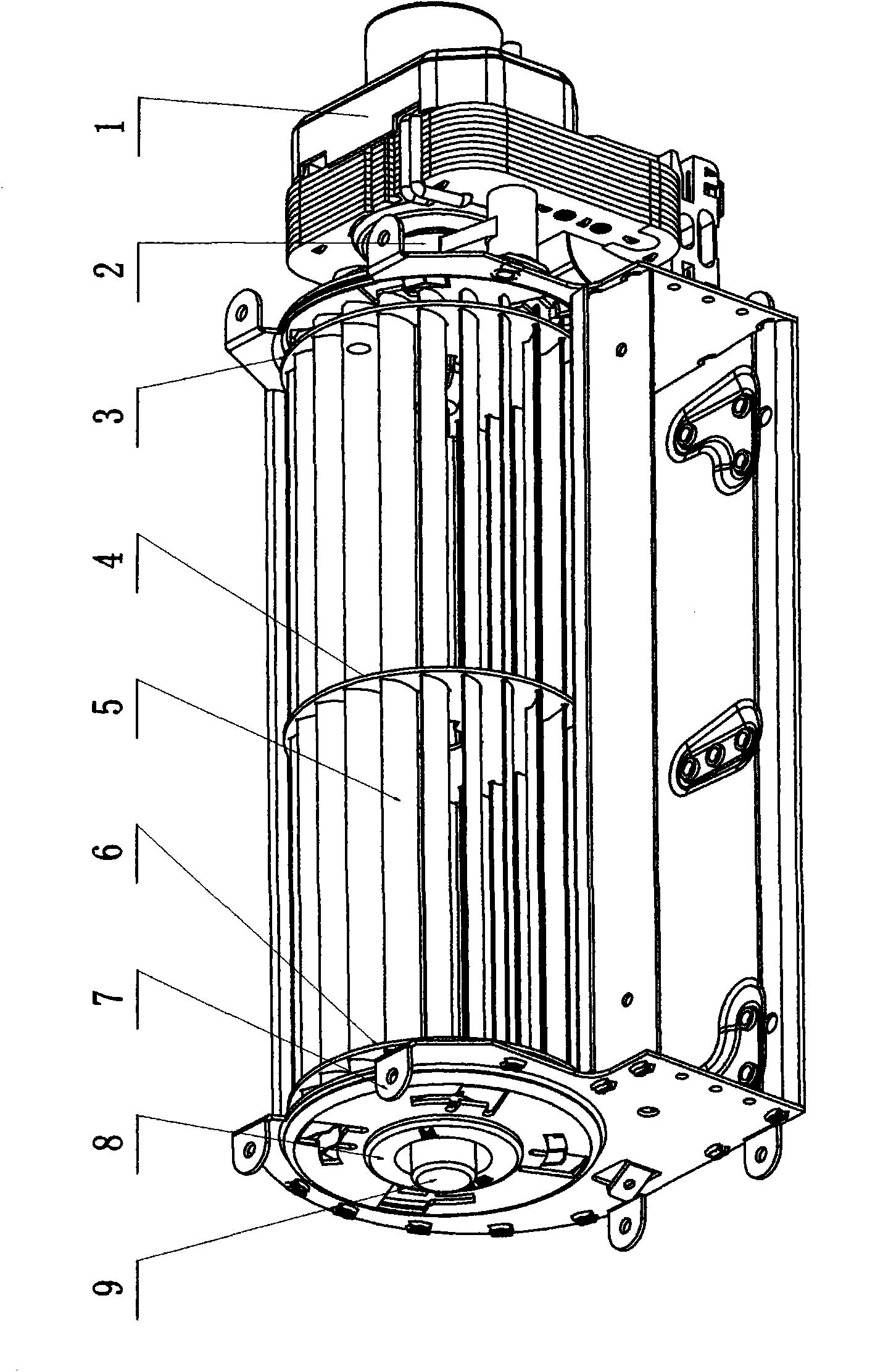

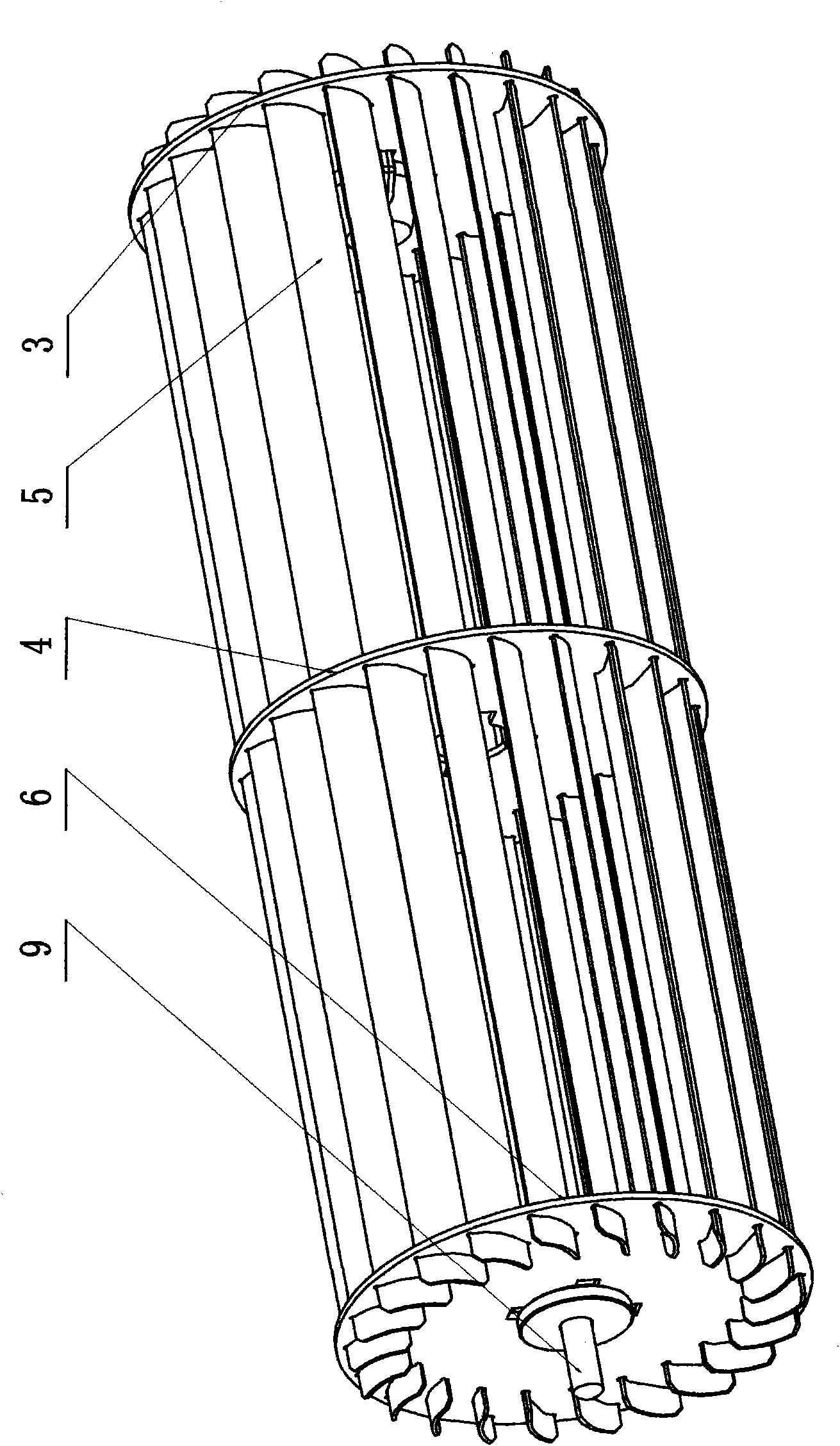

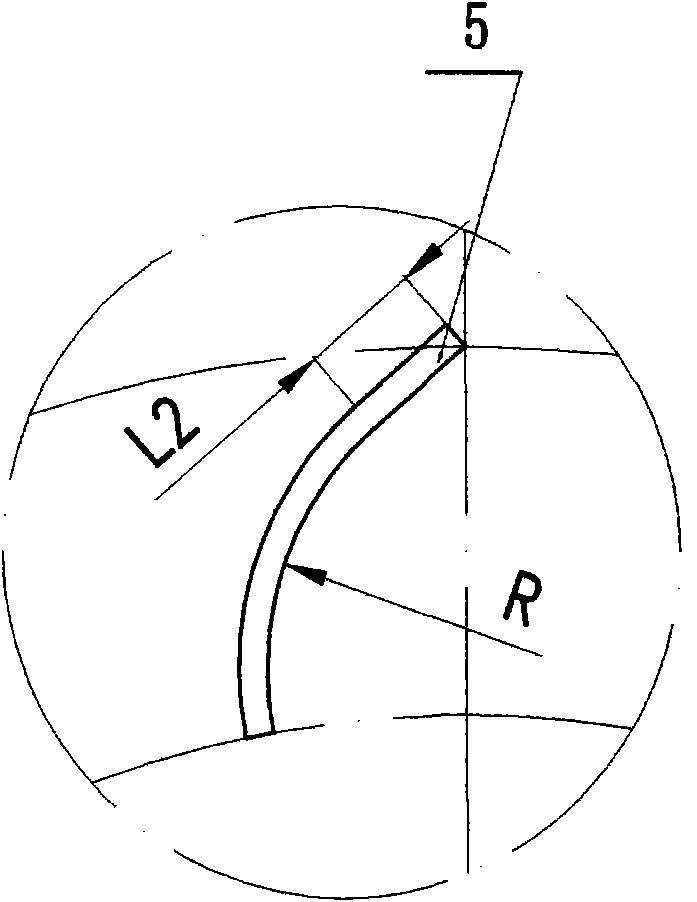

[0029] This embodiment is composed of a motor 1, a coupling 2, a cross-flow impeller, a casing assembly 7 and a bearing seat 8. The main arc section profile of the worm plate of the casing assembly 7 is an eccentric arc, and the casing assembly 7 consists of a volute The shell plate, the volute tongue plate and the side plates at both ends are riveted into a whole. The bearing seat 8 is installed in the middle hole of the two end side plates of the casing assembly 7 . The cross-flow impeller is composed of a left disc 6, a middle disc 4, a right disc 3, an impeller shaft 9, and blades 5 (the number of blades can be 20 to 27 pieces), and the internal shape line of the blade 5 is a (middle) segment The two ends of the arc (tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com