Method for manufacturing radiator of LED street lamp

A technology of LED street lamps and manufacturing methods, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problem that radiators cannot form multi-directional convection circulation, and aluminum extrusion technology cannot be vertical , Die-casting molds are difficult and other problems, to achieve the effect of light weight, material saving and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention is achieved in this way.

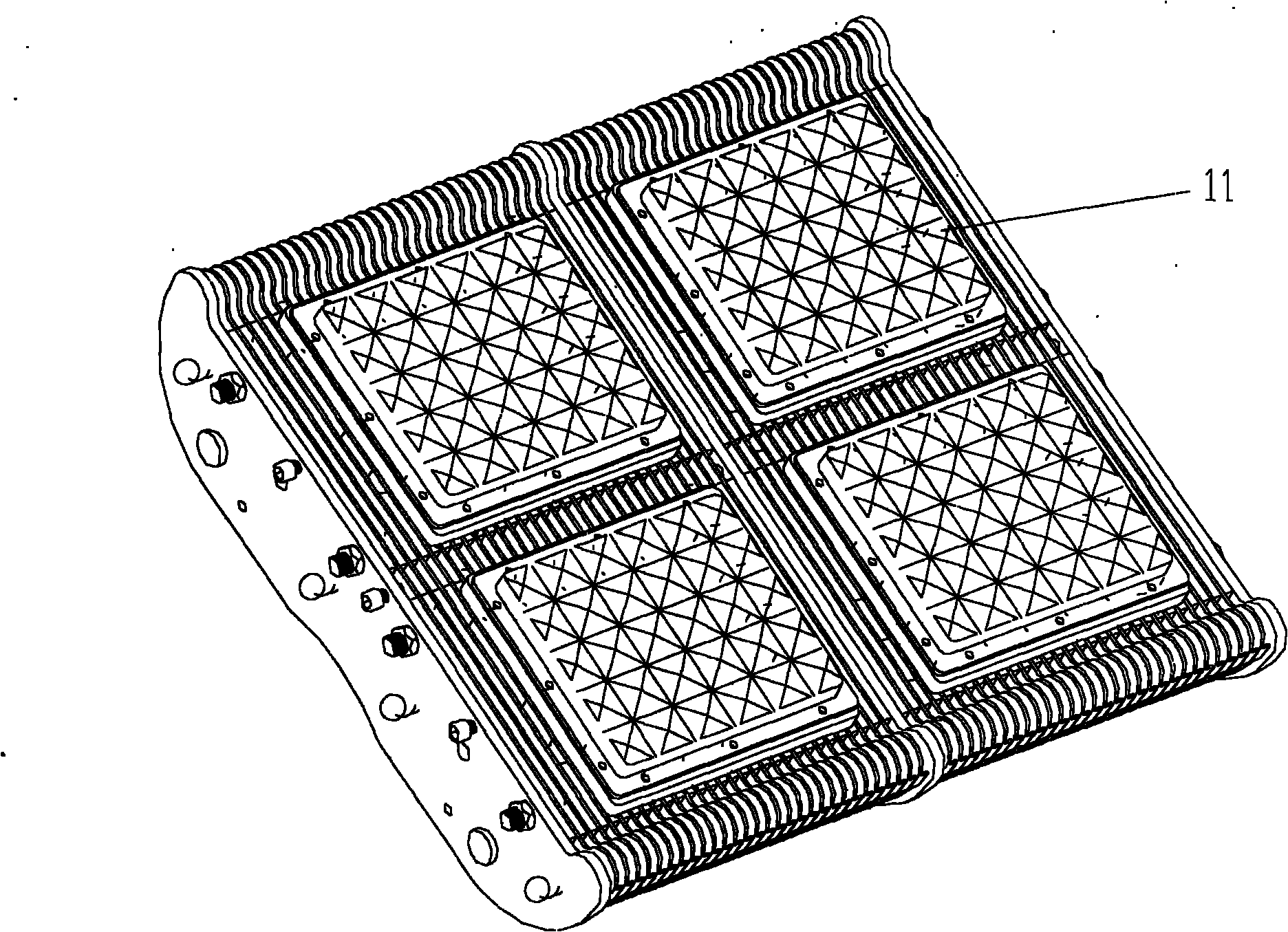

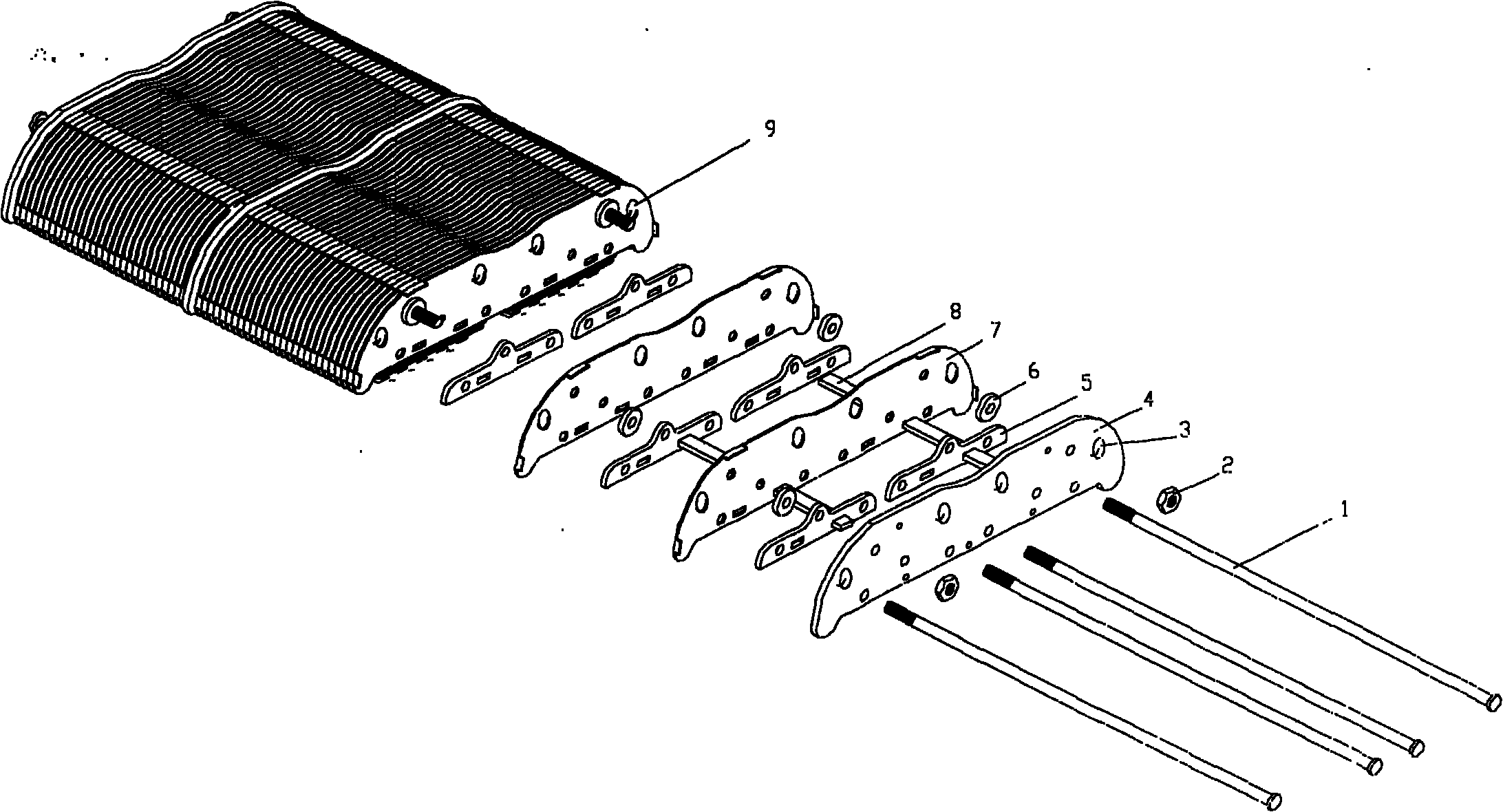

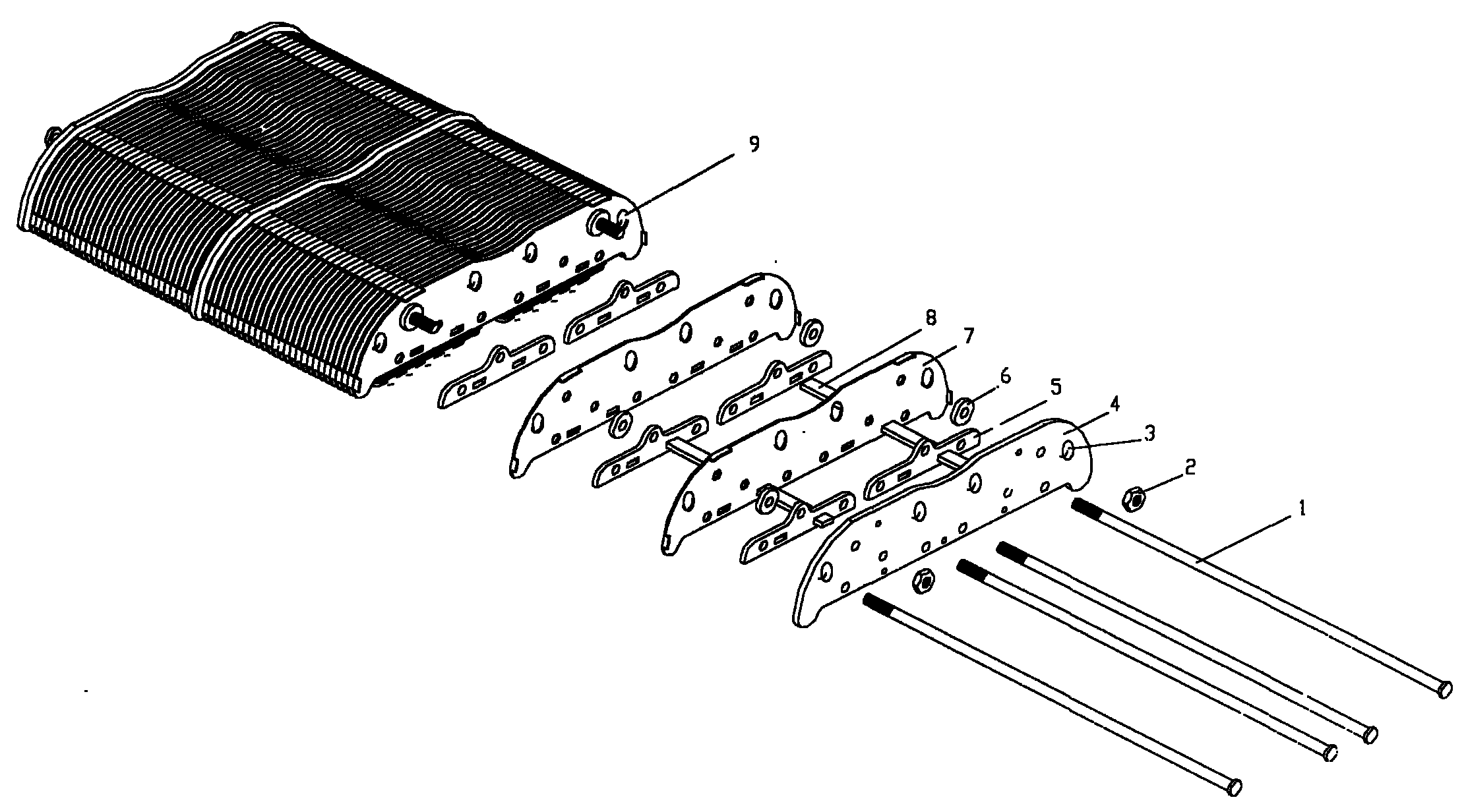

[0022] Such as figure 1 and 2 As shown, a LED street lamp heat sink is composed of an aluminum substrate, fins, layer partitions, screw rods, screws and the like. The heat dissipation fins and layer separators made by stamping are stacked together and fixed with screw screws to form a plane. This plane can be finished. The smooth plane after processing can be more closely combined with the aluminum substrate. A square aluminum profile is strung between the layer separator and the fins, holes are drilled and tapped on the square aluminum profile, and the aluminum substrate is fixed on the radiator with screws, so that the aluminum substrate is in full contact with the radiator. Finally, fix the LED circuit board on the aluminum substrate. And because there are a large number of multi-directional ventilation holes on the radiator, it is conducive to air convection up and down, left and right, fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com